Self-balancing method for cooling water of slag extractor

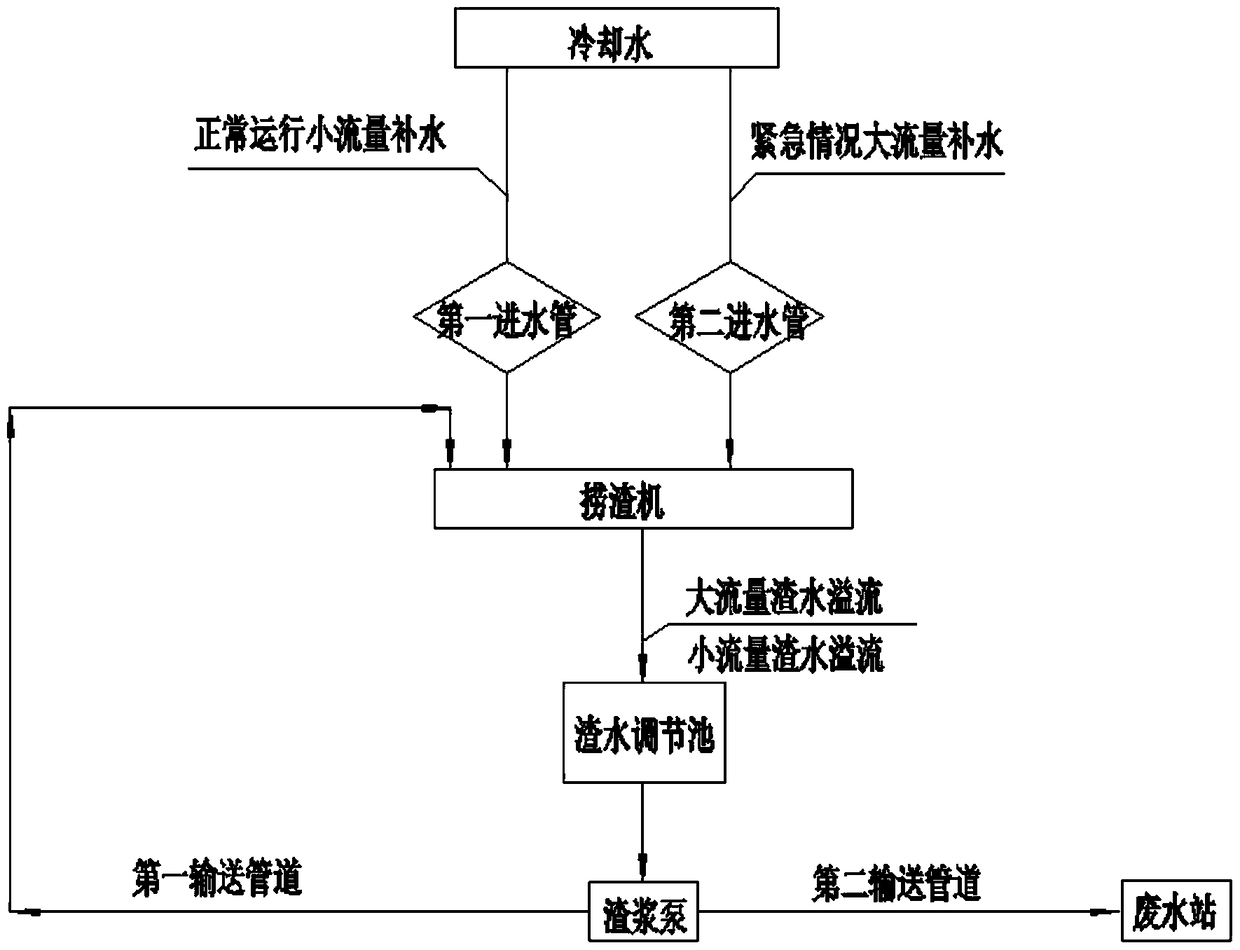

A technology of slag scraper and cooling water, which is applied in the field of coal-fired boiler slag discharge, can solve the problems of increased operating costs, greater influence of water temperature, unfavorable safe and reliable operation of slag scraper, etc., to improve service life and safety reliability , the balance of water replenishment and consumption, and the effect of reducing the number of times of large flow water replenishment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Embodiments of the present invention are described in detail below:

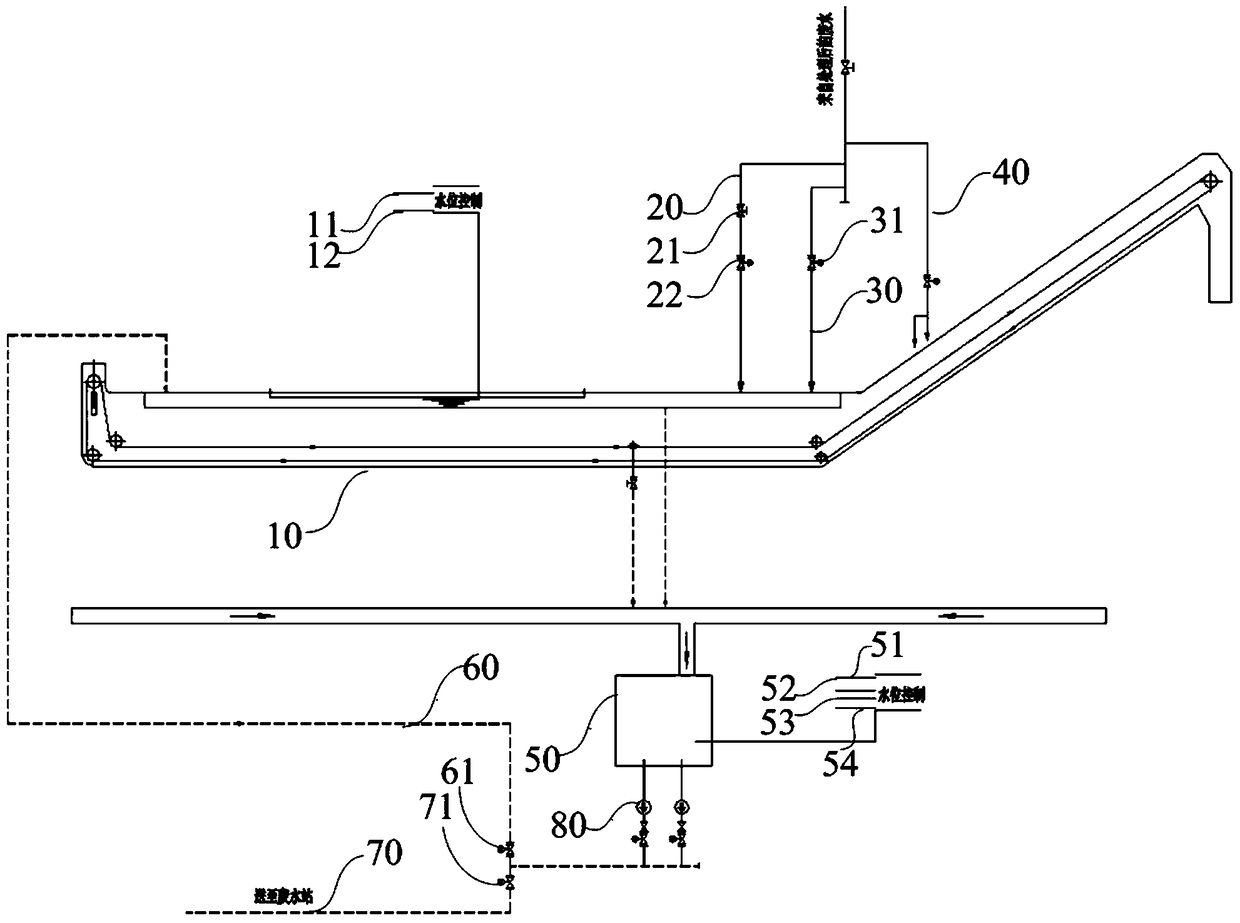

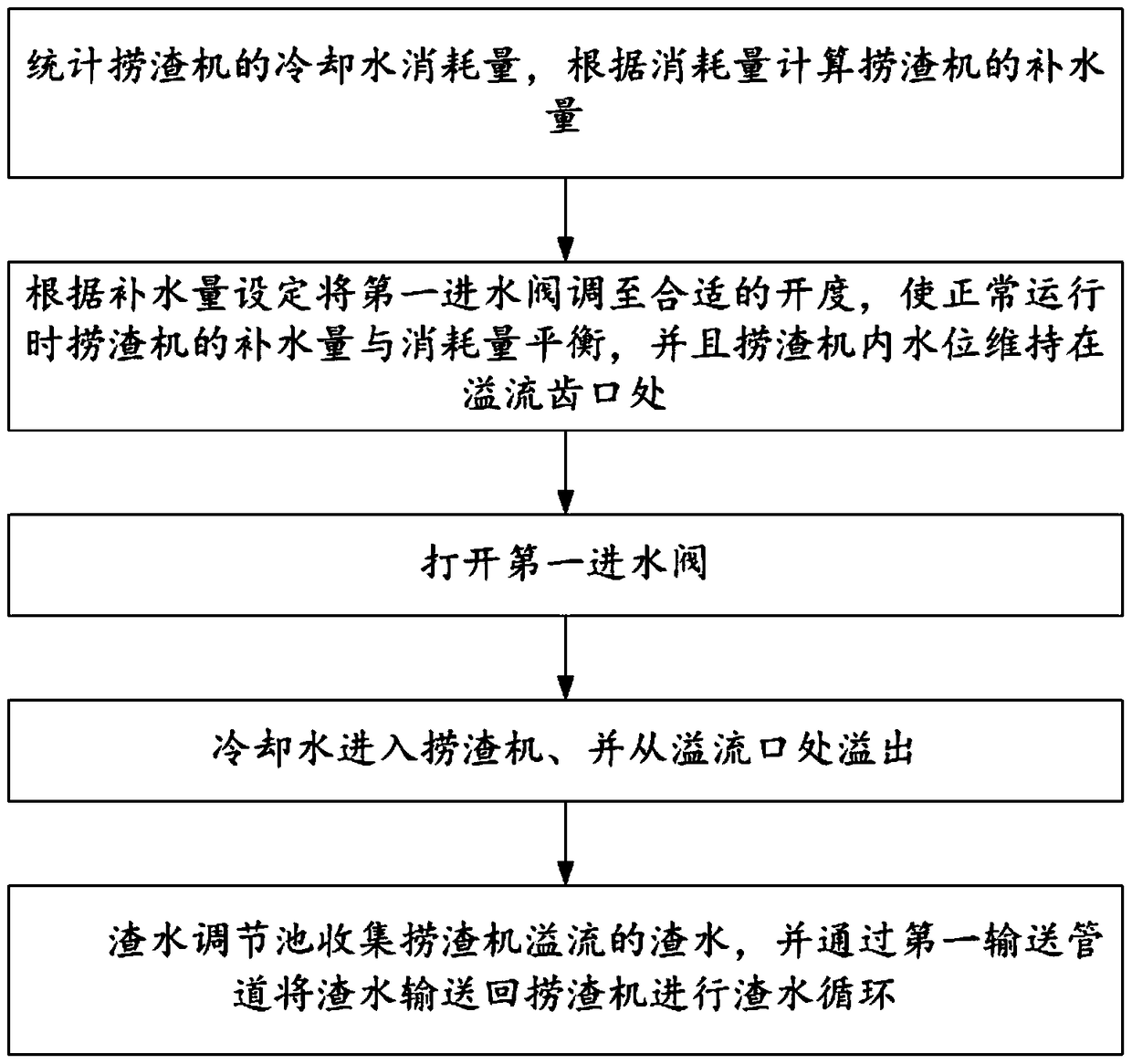

[0050] Such as figure 1 As shown, a self-balancing method for cooling water of a slag removing machine is provided with a first water inlet pipe 20 above the slag removing machine 10, and a first water inlet valve (not shown in the drawings) with an adjustable opening is provided on the first water inlet pipe 20. mark), the slag removal machine 10 is provided with an overflow port (not marked in the accompanying drawings), and the slag removal machine 10 is provided with a slag water regulating tank 50 connected to the overflow port, and the slag water regulating tank 50 is connected to the slag removal machine 10 A first conveying pipeline 60 is arranged between them, and a first conveying valve 61 is arranged on the first conveying pipeline 60. In this embodiment, a frequency conversion speed regulating slurry pump is arranged between the first conveying pipeline 60 and the slag water regulating tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com