Response energy and response impulse testing system of target

A technology of impulse test and test system, which is applied in the direction of measuring device, measuring blasting force, force/torque/work measuring instrument, etc., which can solve the problems of large test error and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

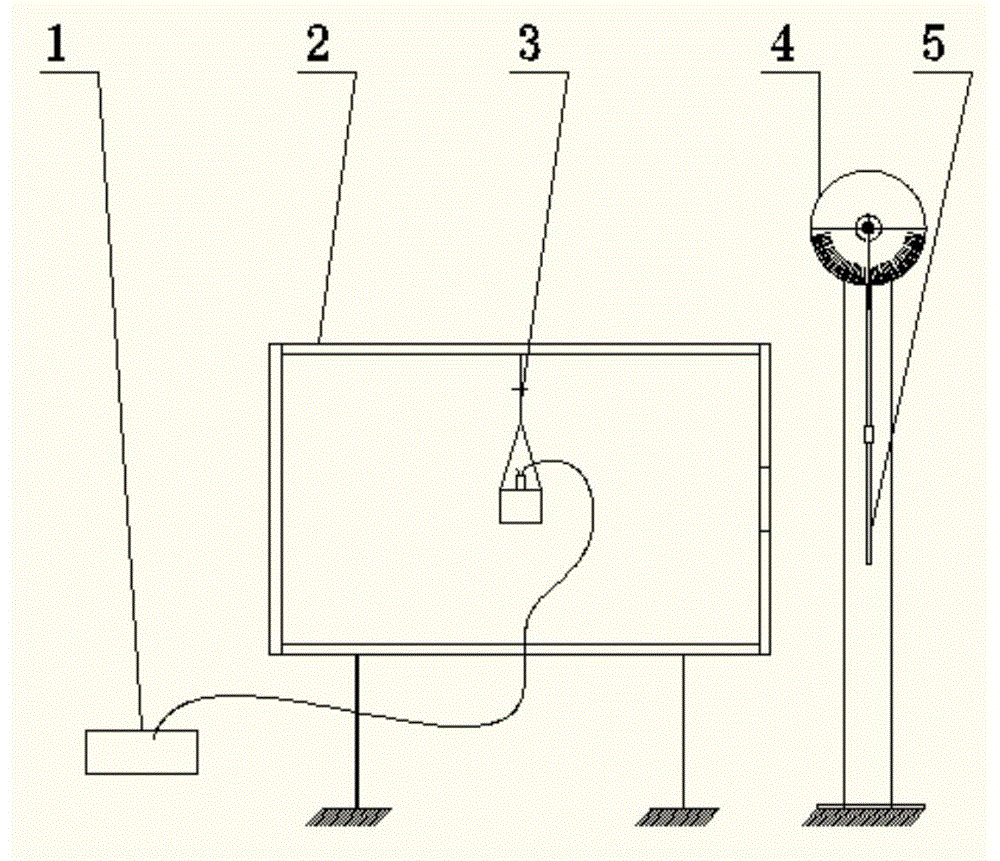

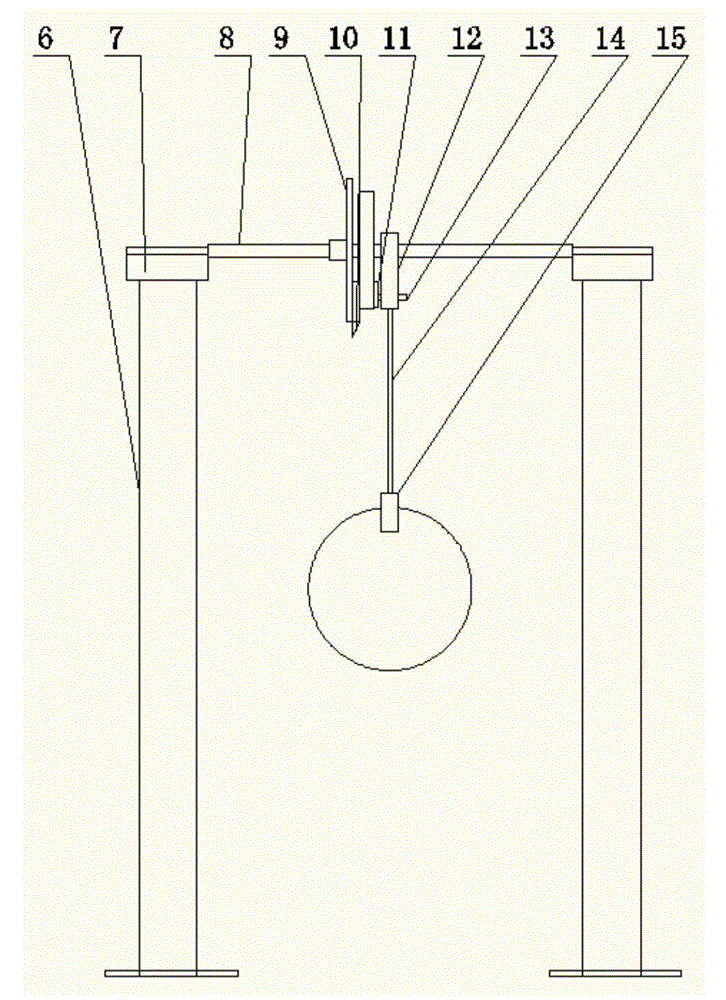

[0030] Described test system, it is characterized in that, test system comprises detonation system and data acquisition and processing system, and detonation system comprises explosion chamber 2, sample frame 3, detonator 1, explosion chamber 2 side openings, sample frame 3 is located in The central position of the explosion chamber is used to fix the explosive sample, and the detonator 1 is connected with the detonator line on the explosive sample through a wire, and is used for detonating the explosive sample; the data acquisition and processing system includes an angle measuring device 4, a swing plate 5, Test the pendulum support 6, the axle seat 7, the transverse axis 8, the transverse axis 8 of the test pendulum support 6 is fixed by two vertical columns and the column is fixed on the axle seat 7, and the transverse axis 8 is horizontally placed on the two columns, The pendulum plate 5 is fixed by two cycloids perpendicular to the bracket 6, and facing the side hole of th...

Embodiment 2

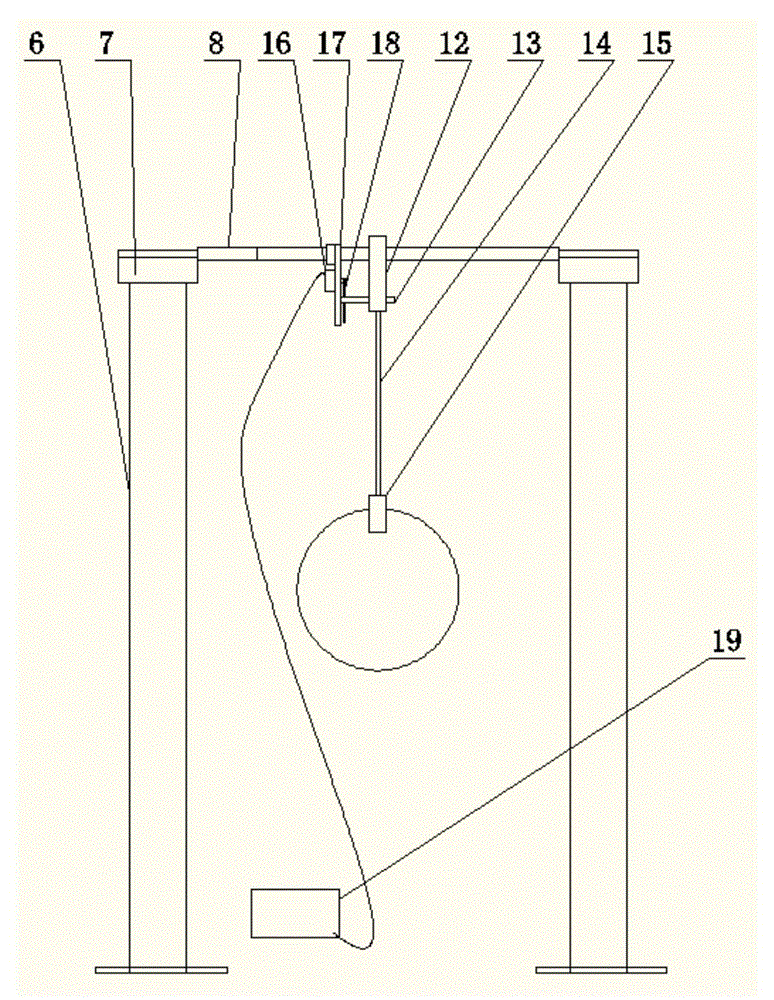

[0041] Described test system, it is characterized in that, test system comprises detonation system and data acquisition and processing system, and detonation system comprises explosion chamber 2, sample frame 3, detonator 1, explosion chamber 2 side openings, sample frame 3 is located in The central position of the explosion chamber is used to fix the explosive sample, and the detonator 1 is connected with the detonator line on the explosive sample through a wire, and is used for detonating the explosive sample; the data acquisition and processing system includes an angle measuring device 4, a swing plate 5, Test the pendulum support 6, the axle seat 7, the transverse axis 8, the transverse axis 8 of the test pendulum support 6 is fixed by two vertical columns and the column is fixed on the axle seat 7, and the transverse axis 8 is horizontally placed on the two columns, The pendulum plate 5 is fixed by two cycloids perpendicular to the bracket 6, and facing the side hole of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com