Anti-freezing pressure gauge short casing joint

A pressure gauge and short-circuit technology, which is used in the measurement of fluid pressure, measuring devices, instruments, etc., can solve the problems of pressure gauge damage, breakage, pointer exceeding the maximum range, etc., and achieve the effect of convenient and stable connection and simplified replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

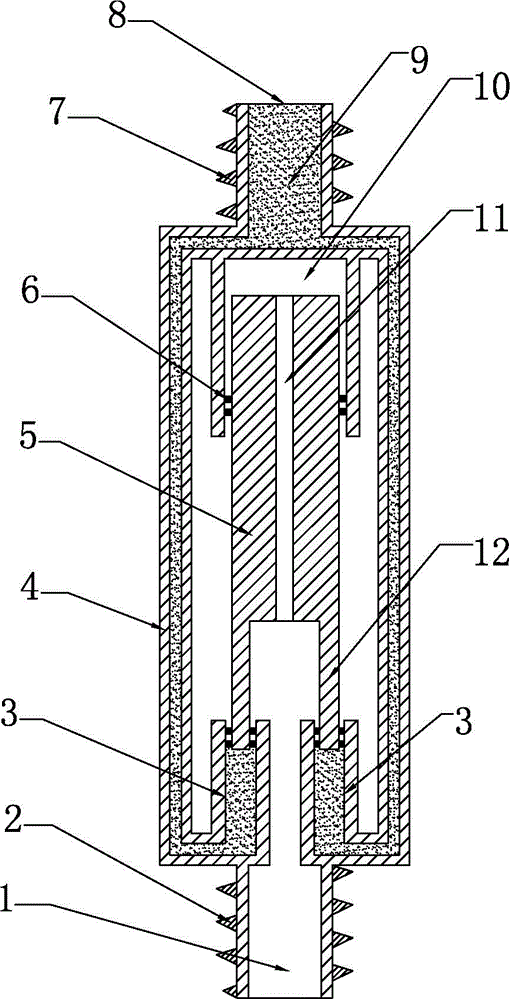

[0014] The reference signs in the drawings of the specification include: short-circuit inlet 1, inlet external thread 2, second cavity 3, casing 4, drive rod 5, sealing ring 6, outlet external thread 7, short-connect outlet 8, vaseline 9, A first cavity 10 , a through hole 11 , and a pressing rod 12 .

[0015] The embodiment is basically as attached figure 1 As shown: the antifreeze pressure gauge is short-circuited, and the antifreeze pressure gauge is short-circuited, including a casing 4. The lower end of the casing 4 is provided with a short-circuit inlet 1, and the wall of the casing 4 of the short-circuit inlet 1 is provided with a connection with the measured medium pipeline. The inlet external thread 2 connected to the valve, the upper end of the casing 4 is provided with a short-circuit outlet 8, the wall of the casing 4 of the short-circuit outlet 8 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com