Multi-tool-bit type center cooling drill bit

A technology with multiple cutter heads and drill bits, which is used in repairing drills, drilling tool accessories, drilling/drilling equipment, etc. And the effect of stably disassembling and assembling the cutter head, improving the service life and slowing down the extraction frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

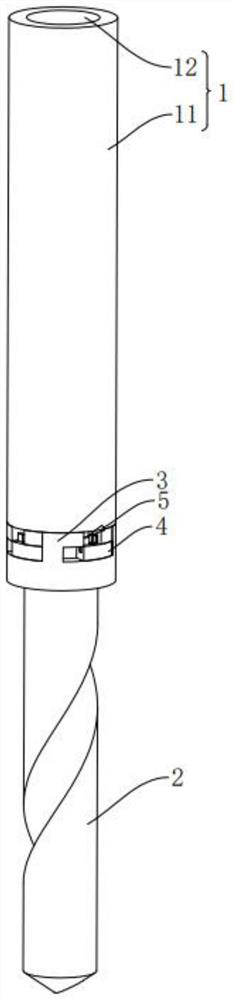

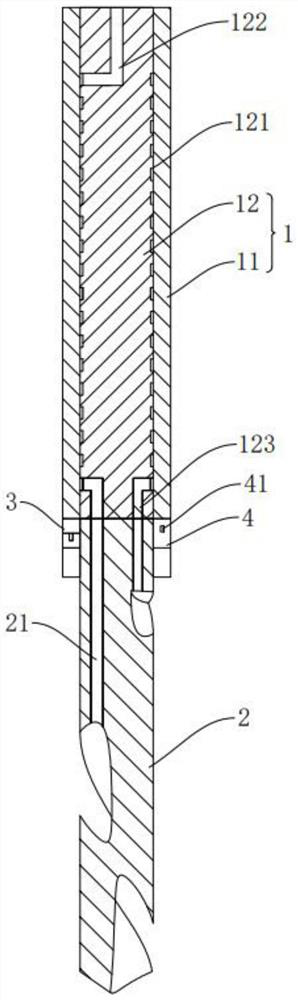

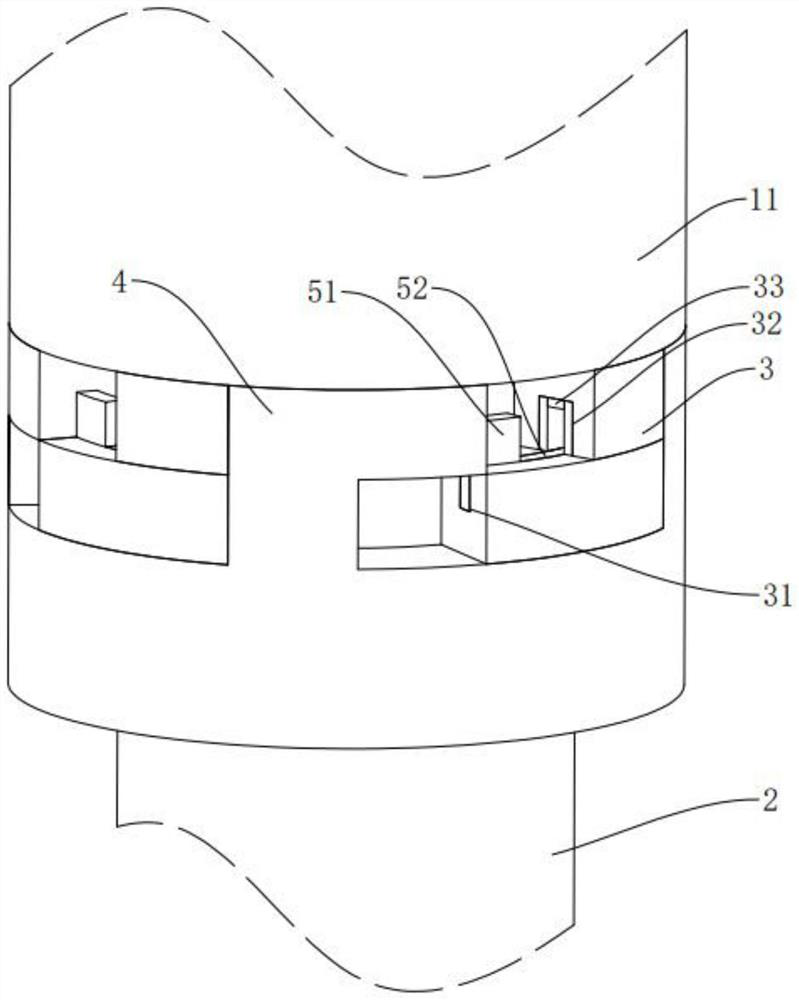

[0035] The embodiment of the present application discloses a multi-tip type central cooling drill. refer to figure 1 with figure 2 A multi-cutter central cooling drill bit includes a connected cutter bar 1 and a cutter head 2, the cutter bar 1 includes an outer ring 11 and an inner rod 12, the outer ring 11 is fixedly sleeved on the outer periphery of the inner rod 12, and the cutter head 2 One end of one end and one end of inner rod 12 are fitted and arranged. The outer wall of the inner rod 12 is provided with a first cooling waterway 121 around the outer circumference of the inner rod 12 , the end of the inner rod 12 away from the cutter head 2 is provided with a water injection hole 122 , and the end of the inner rod 12 facing the cutter head 2 is provided with a water outlet hole 123 and a water injection hole 122 The water outlet hole 123 communicates with the first cooling water channel 121 . The cutter head 2 is provided with a second cooling water channel 21 , and...

Embodiment 2

[0044] refer to Figure 5 The difference between this embodiment and Embodiment 1 is that no return spring 42 is provided in the positioning groove 41, and the end of the cutter bar 1 facing the cutter head 2 is connected with a threaded column 124, and the threaded column 124 is coaxially arranged with the tool bar 1. The cutter head 2 is connected with a threaded hole 22 , and the threaded post 124 extends into the threaded hole 22 and is threadedly connected with the cutter head 2 .

[0045] The implementation principle of a multi-cutter central cooling drill bit in the embodiment of the present application is as follows: the cutter bar 1 is threadedly connected with the cutter head 2 through the threaded column 124. Under the action of the thread, when the electromagnet 53 is accidentally powered off, the cutter head 2 It will not fall off suddenly and cause accidents, and it can give the operator a certain amount of time to stop the operation, and the safety is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com