Prefabricated part mortise grouting device for assembly type subway station and using method

A technology for prefabricated components and subway stations, applied in underwater structures, infrastructure engineering, buildings, etc., can solve the problems of high grouting pressure, incomplete matching, messy, etc., to increase grouting pressure, reduce space occupation, Neat effect on the construction site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

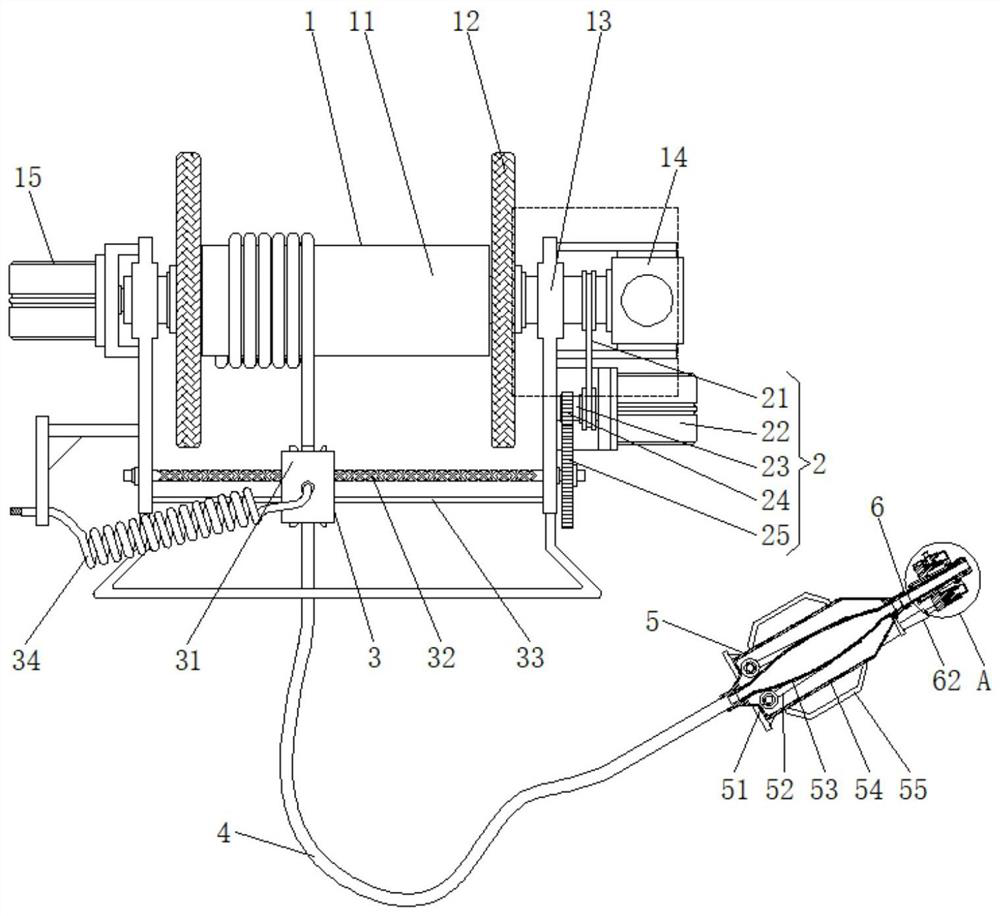

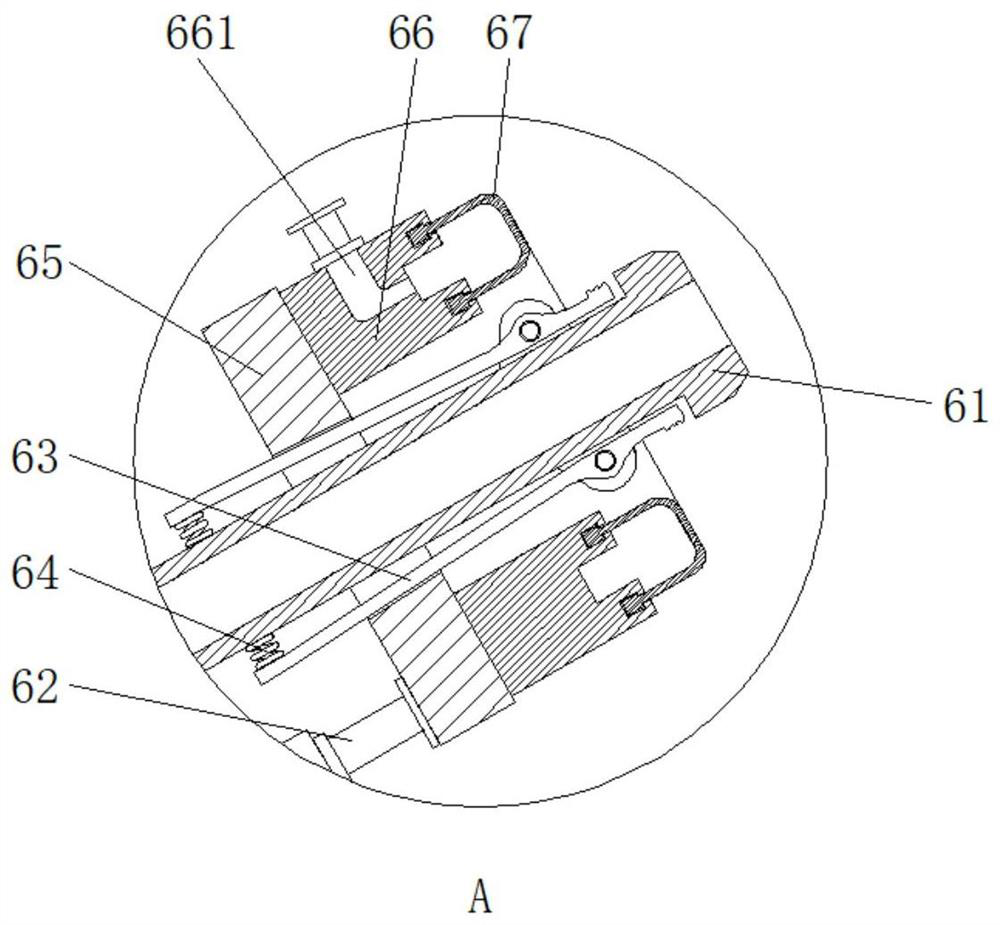

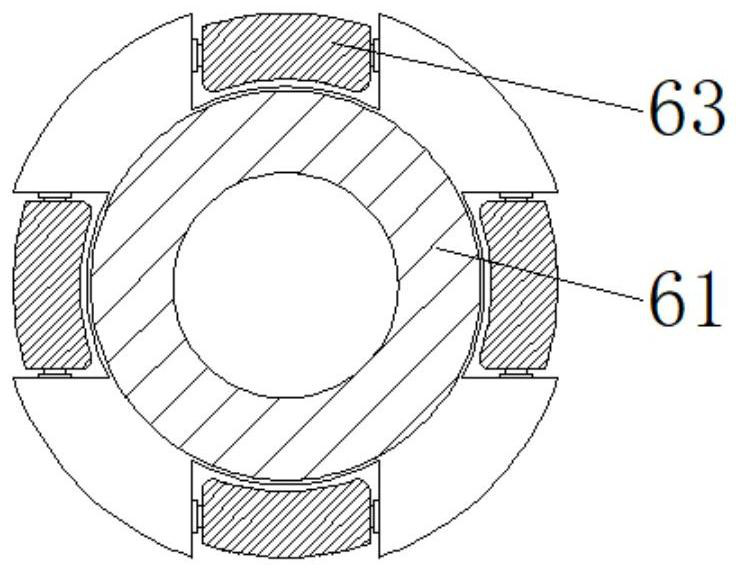

[0053] The present invention provides a prefabricated component tongue and groove grouting device for prefabricated subway stations through improvement, such as Figure 1-Figure 15 As shown, a prefabricated component tongue and groove grouting device for a prefabricated subway station includes a grout feeding pipe 4, one end of the grout feeding pipe 4 is connected to a grouting and rolling pipe integrated machine 1, and the other end of the grout feeding pipe 4 is passed through an increaser. One end of the self-locking grouting pipe 6 is connected to the pressing mechanism 5, and one side of the all-in-one grouting pipe rolling machine 1 is connected to the cleaning type cable arrangement 3 through the synchronous transmission mechanism 2, and the grout feeding pipe 4 is installed in the cleaning type row Connector 3.

[0054] The all-in-one grouting and coiling machine 1 can integrate the power function of grouting, the function of retracting and unwinding the pipe, and the...

Embodiment 2

[0068] The present invention provides a prefabricated component tongue and groove grouting device for prefabricated subway stations through improvement, such as Figure 1-Figure 15 As shown, a prefabricated component tongue and groove grouting device for a prefabricated subway station includes a grout feeding pipe 4, one end of the grout feeding pipe 4 is connected to a grouting and rolling pipe integrated machine 1, and the other end of the grout feeding pipe 4 is passed through an increaser. One end of the self-locking grouting pipe 6 is connected to the pressing mechanism 5, and one side of the all-in-one grouting pipe rolling machine 1 is connected to the cleaning type cable arrangement 3 through the synchronous transmission mechanism 2, and the grout feeding pipe 4 is installed in the cleaning type row Connector 3.

[0069] The booster mechanism 5 includes a push wheel 51, a soft rubber tube 53, a frame 54, a push-pull device 56 and a synchronous bar 57. Both sides of th...

Embodiment 3

[0074] The present invention provides a prefabricated component tongue and groove grouting device for prefabricated subway stations through improvement, such as Figure 1-Figure 15 As shown, a prefabricated component tongue and groove grouting device for a prefabricated subway station includes a grout feeding pipe 4, one end of the grout feeding pipe 4 is connected to a grouting and rolling pipe integrated machine 1, and the other end of the grout feeding pipe 4 is passed through an increaser. One end of the self-locking grouting pipe 6 is connected to the pressing mechanism 5, and one side of the all-in-one grouting pipe rolling machine 1 is connected to the cleaning type cable arrangement 3 through the synchronous transmission mechanism 2, and the grout feeding pipe 4 is installed in the cleaning type row Connector 3.

[0075] The all-in-one machine 1 for grouting and coiling includes a drum 11, a wheel body 12, a bracket 13, a feed hopper 14, a grouting control motor 15, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com