A device and method for testing the safety performance of resin diamond soft grinding discs

A technology of safety performance and testing device, applied in the direction of applying stable torque to test the strength of materials, can solve the problems of large errors, incomplete testing items, inconvenient operation, etc., and achieve the effect of eliminating errors, uniform testing conditions, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

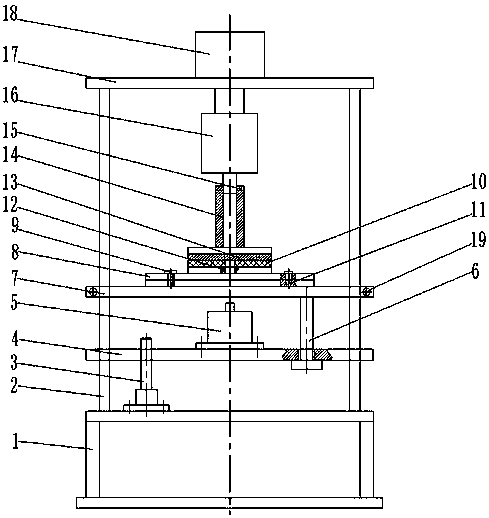

[0022] The safety performance testing device for resin diamond soft grinding discs provided by the present invention comprises a sample fixing unit, a torque loading unit and a control unit, the sample fixing unit includes a frame 1, and a guide rail 2 is arranged on the frame 1, and the guide rail 2 is arranged from bottom to top. The movable beam 4 and the base plate 7 that can move along the guide rail 2, the movable beam power device is set on the frame 1, preferably a screw nut mechanism 3, the fixed load sensor 5 is fixed on the movable beam 4, and the load sensor 5 is used to display the nylon during the test. The buckle and the soft grinding plate are subject to pressure, the movable beam 4 and the base plate 7 are movably connected by the connecting bolt 6, the connecting screw 6 passes through the through hole on the movable beam 4 and is fixed on the base plate 7, the length of the connecting bolt 6 is greater than the height of the load cell 5, The length of the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com