Housing of multichannel speed sensor mounted at locomotive axle end

A speed sensor, multi-channel technology, applied in instruments, speed/acceleration/shock measurement, speed/acceleration/shock meter detailed information, etc., can solve the hidden danger of insulation voltage performance, cumbersome phase debugging steps, and inclined printed board components. and other problems, to achieve the effect of simple tolerance control, solving production bottleneck problems, and convenient phase adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the embodiments of the accompanying drawings.

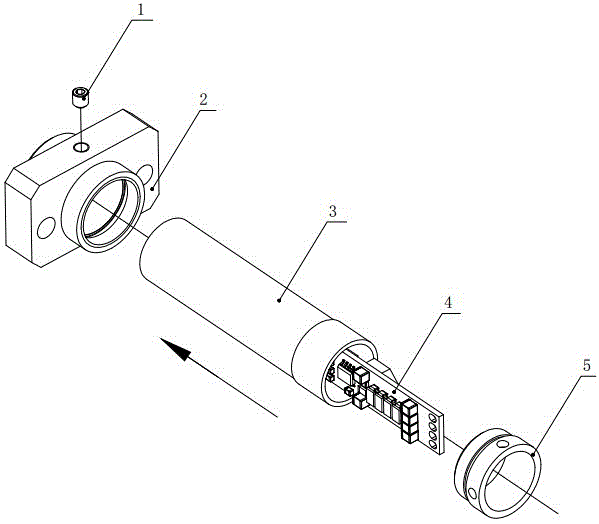

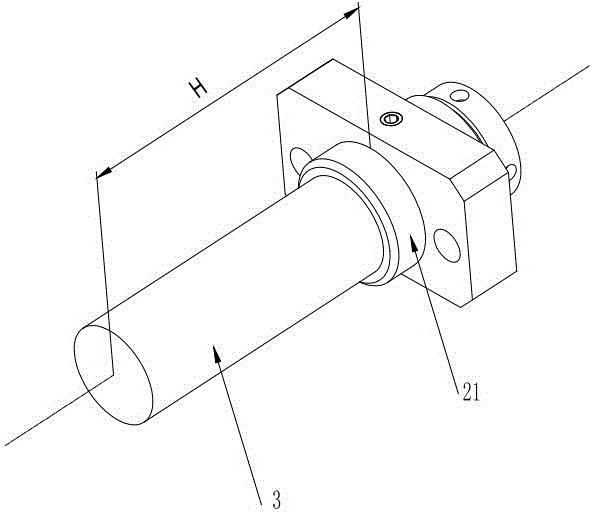

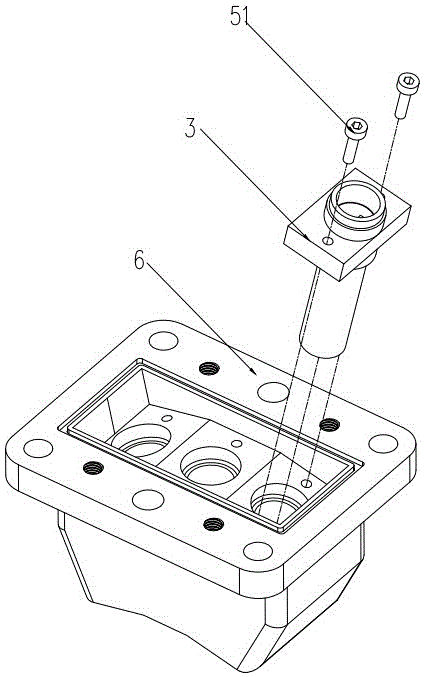

[0032] Such as Figure 5 As shown, the multi-channel locomotive shaft end speed sensor housing includes an integrated sensor head housing 8 , a printed board assembly 4 , and a printed board assembly fixing ring 7 .

[0033] The above-mentioned one-piece sensor head housing 8 is a cylinder, which includes a closed head 81, a cavity 85 for accommodating the printed board assembly 4, and a tail end 84. The tail end 84 is a positioning ring, and a positioning groove is arranged on the positioning ring. 82, used to fix the fixing ring 7 of the printed board assembly.

[0034] The above-mentioned printed board fixing ring 7 includes a ring that can be sleeved on the tail end of the integrated sensor head housing, and the inner ring of the ring is symmetrically provided with a protrusion 73 corresponding to the positioning groove 82 at the tail end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com