Test seat of passive microwave radio frequency transformer

A microwave radio frequency, test seat technology, applied in the direction of the measuring device shell, etc., can solve the problems of inability to easily complete the device test, inability to complete the welding, damage to the properties of the device, etc., to achieve stable and reliable test data, improve test reliability and efficiency, The effect of reducing power attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

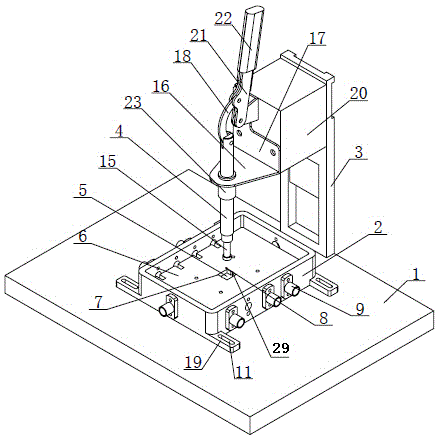

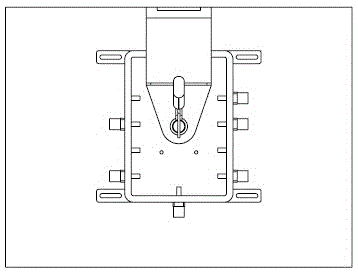

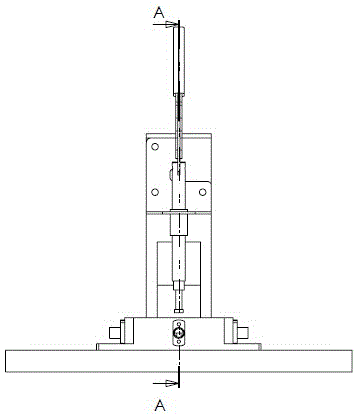

[0024] Such as Figure 1~Figure 6 As shown, a test seat for a passive microwave radio frequency transformer includes a cavity 2, a circuit board 5, a positioning plate 6 and a spring thimble fixture 4, and the cavity with an upper end face of the cavity 2 is fixedly connected to the base 1 , the circuit board 2 and the positioning board 6 are fixedly placed in sequence from bottom to top in the cavity 2, the circuit board 5 is connected to the monitoring equipment through wires, the positioning board 6 is provided with a groove 7 for placing the transformer, and the groove A symmetrical notch 29 is arranged inside to facilitate the removal of the test device through tweezers. The spring thimble clamp 4 is fixedly connected to the column 3, and is provided with a pressure rod 25 that can be elastically restored and stretched. The position of the pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com