Virtual temperature sampling control device and method for induction heating

A technology of induction heating and control components, applied in the field of control, can solve the problems of temperature signal anti-interference ability, damage equipment, reliable operation of equipment that affects the quality of processed products, etc., to achieve strong anti-interference ability, improve accuracy and stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable those skilled in the art to understand the technical solution of the present invention, the appended preferred embodiments are attached with accompanying drawings for detailed description. The embodiments illustrated in the accompanying drawings are only used to illustrate the technical solution of the present invention, and are not intended to limit the present invention. invention.

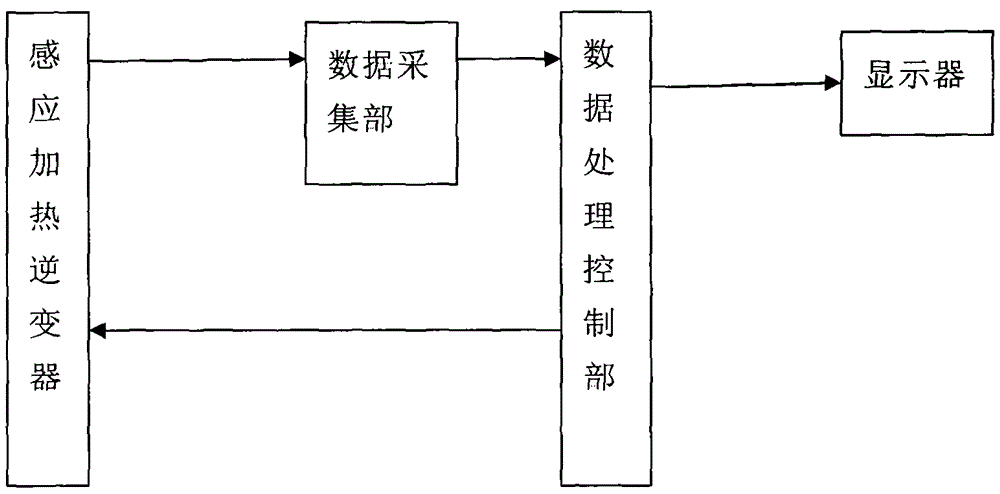

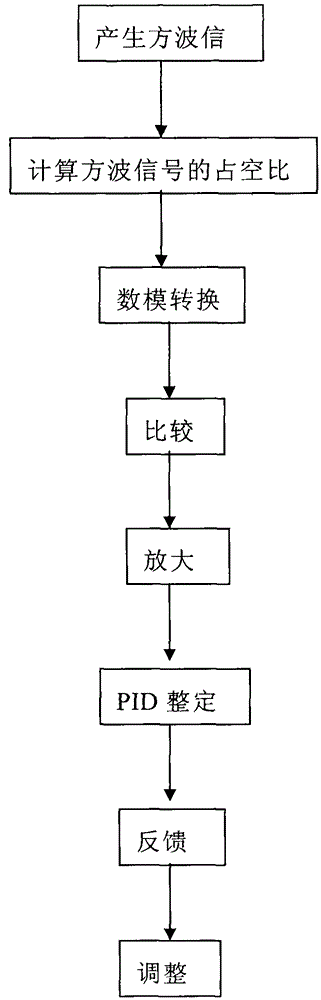

[0022] Please refer to figure 1 , 2 , this article combines the attached figure 1 The structural block diagram of the virtual temperature sampling system and the appendix figure 2 The flow chart of the temperature control method will introduce the embodiment of the present invention in detail.

[0023] The virtual temperature sampling system of the present invention is mainly composed of an induction heating inverter, a data acquisition component, and a data processing control component.

[0024] Induction heating inverters contain heating coils and power switch tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com