Intelligent grouting system

An intelligent, grouting pump technology, applied in general control systems, control/regulation systems, non-electric variable control and other directions, can solve the problems of high labor intensity, tampering with grouting data, inaccurate proportions, etc. The effect of saving labor costs and ensuring personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

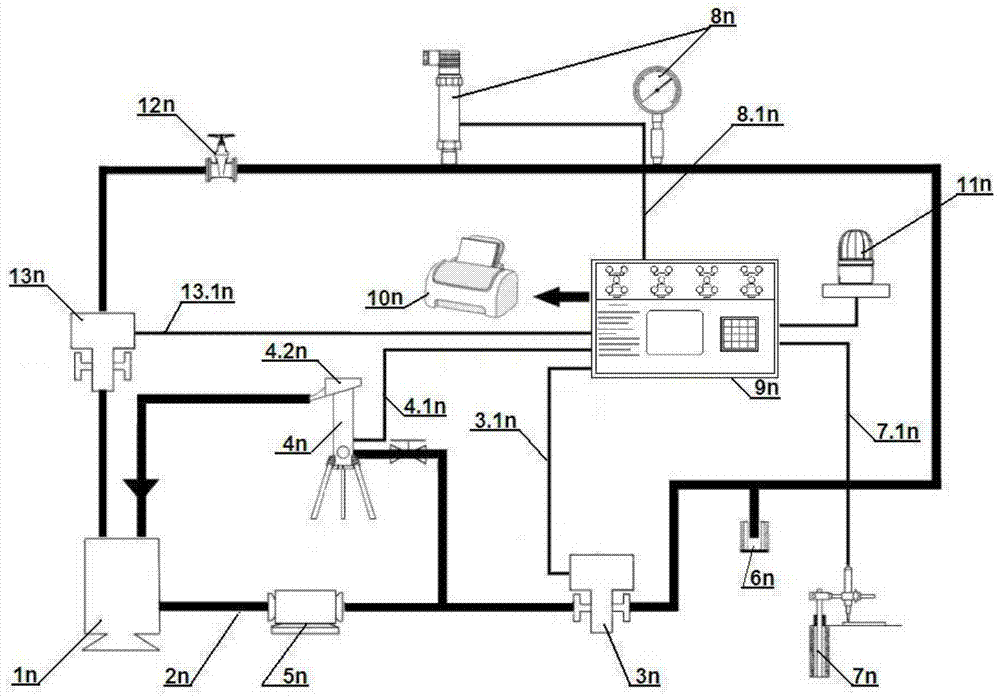

[0028] The intelligent grouting system of this embodiment is composed of the following parts, which will be described one by one with reference to the accompanying drawings.

[0029] 1) see Figure 4 , set up a single-chip microcomputer control system 6, a keyboard 7, and a display 8. The single-chip microcomputer control system has an optocoupler isolation circuit 6.1, an A / D conversion 6.2, a single-chip microcomputer 6.3 and a communication port 6.7 which are sequentially connected along the input information transmission direction. Keyboard 7 is used for input setting, is connected with single-chip microcomputer keyboard interface 6.8. Display 8 is used for displaying data, and is connected with MCU display interface 6.9.

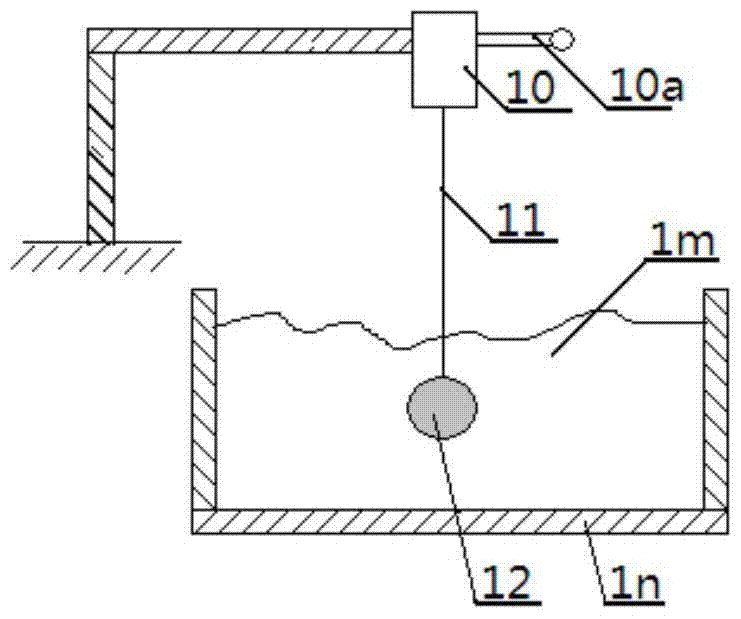

[0030] 2) On-line cement slurry hydrometer: see image 3 In the grouting detection and recording system, a tension sensor 10 is fixed above the grouting barrel 1n filled with the measured cement slurry 1m. The lower end of the tension sensor suspends a...

Embodiment 2

[0044] Embodiment 2: except that the following features are different from Embodiment 1, all the other are the same.

[0045]

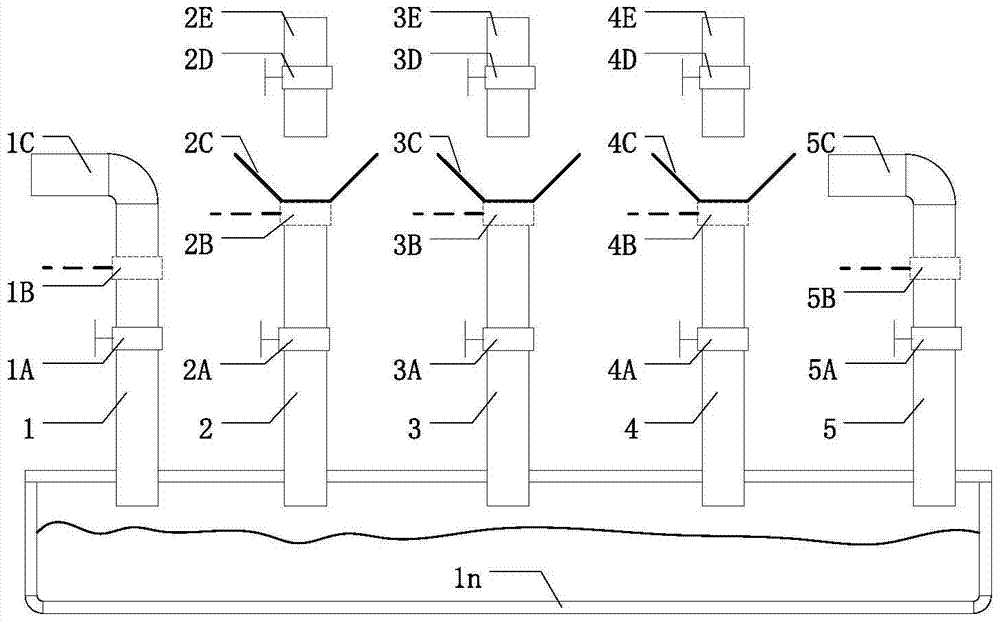

[0046] 1) see figure 2 , the following two pipelines and devices for inserting into water and thick slurry respectively are arranged and inserted in the pulping barrel 1n:

[0047] ① Insert the tap water pipe 1 equipped with the water pipe solenoid valve 1A, and the inlet end of the tap water pipe communicates with the tap water supply pipeline 1C equipped with the water flow sensor 1B. ⑤ Insert the thick slurry pipe 5 equipped with the thick slurry solenoid valve 5A, and the inlet end of the thick slurry pipe is connected with the thick slurry supply pipeline 5C equipped with the thick slurry flow sensor 5B.

[0048] 2) see Figure 4 , the above-mentioned water flow sensor 1B, thick slurry flow sensor 5B, tension sensor 10 (see image 3 ) The electrical signal output terminals of the three sensors in total are connected to the input terminal of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com