Touch display panel, manufacturing method and repairing method thereof

A technology of a touch display panel and a manufacturing method, which are applied in the directions of instruments, electrical digital data processing, and data processing input/output processes, etc., can solve problems such as reducing the aperture ratio of a display device, and achieve the effect of reducing the influence of the aperture ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

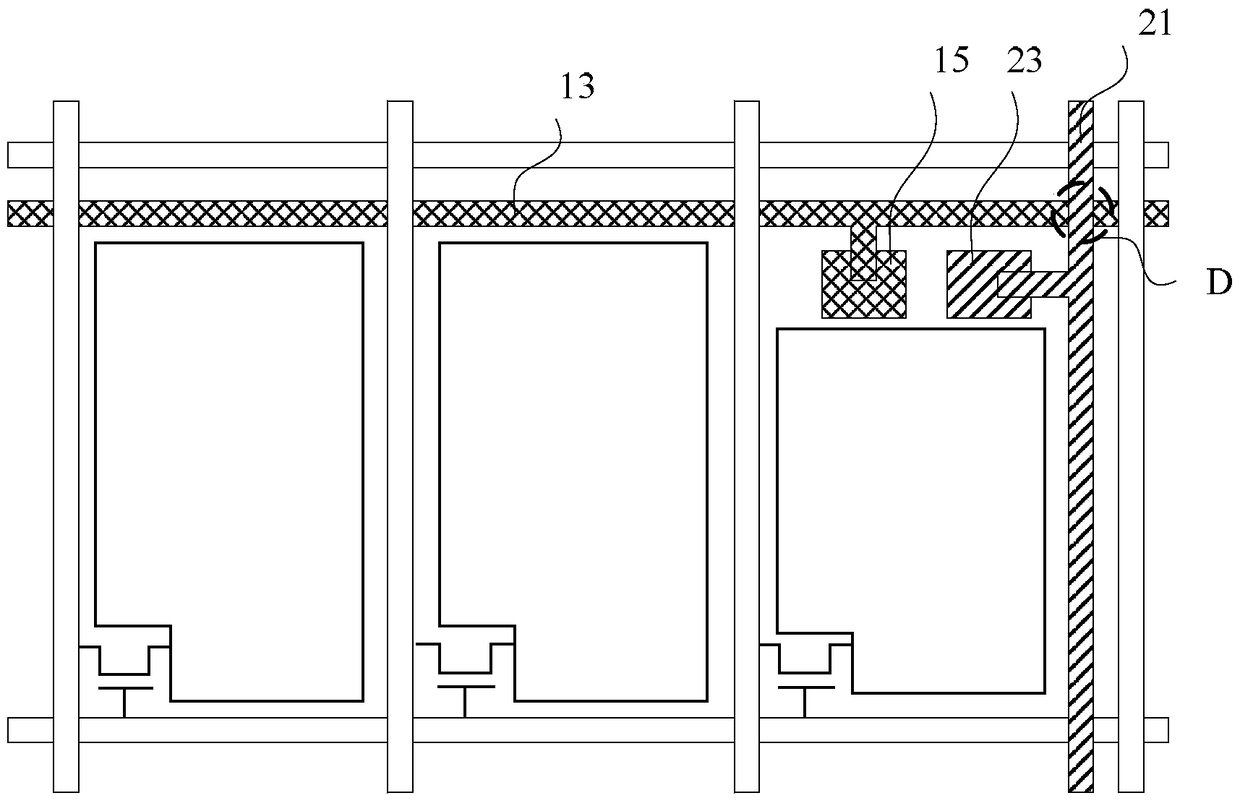

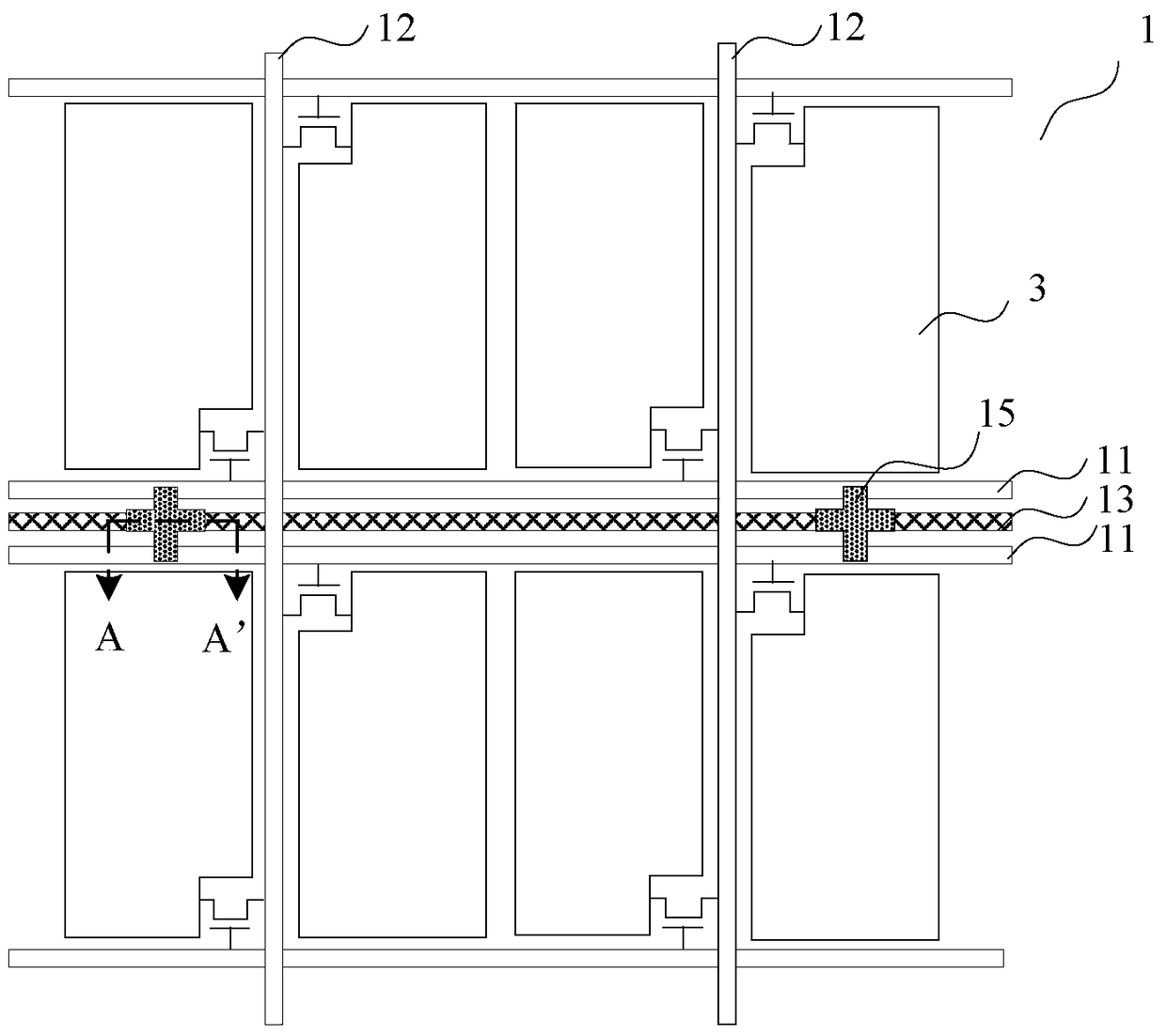

[0035] An embodiment of the present invention provides a touch display panel, such as Figure 2-Figure 7 As shown, the touch display panel includes a first substrate 1 and a second substrate 2 that are oppositely arranged. The first substrate 1 includes a plurality of first signal lines 11 parallel to each other and a plurality of second signal lines 12 parallel to each other. The first signal line 11 and the second signal line 12 are intersected and insulated.

[0036] The first substrate 1 further includes a plurality of first touch electrode traces 13 parallel to the first signal traces 11, and an insulating layer 14 and a first touch electrode 15 sequentially arranged on the first touch electrode traces 13, The insulating layer 14 is provided with a via hole 16 corresponding to the first touch electrode 15 , and the first touch electrode 15 is electrically connected to the first touch electrode wire 13 through the via hole 16 .

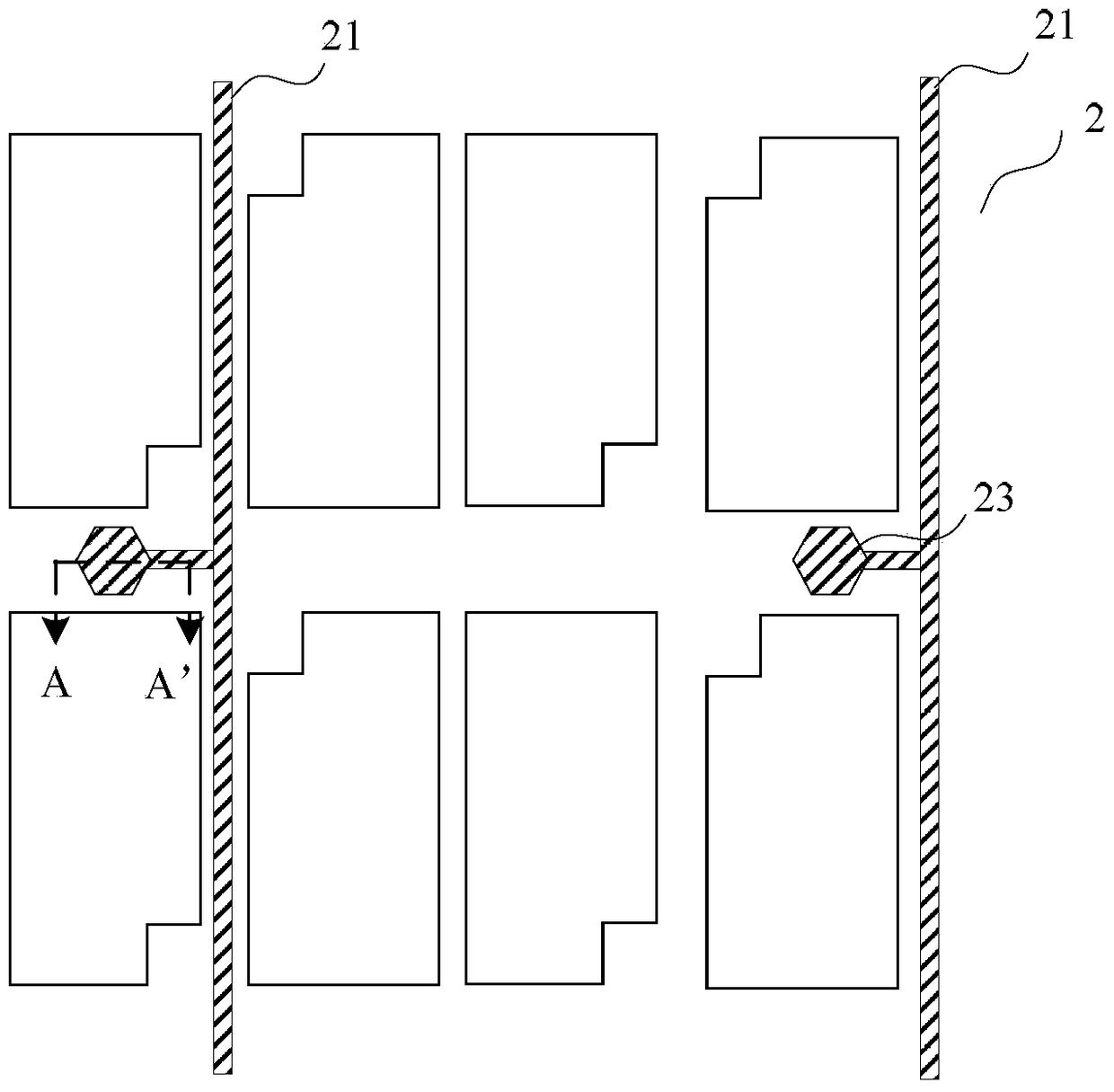

[0037]The second substrate 2 includes a se...

Embodiment 2

[0058] An embodiment of the present invention provides a method for manufacturing a touch display panel, the following combination Figure 2-Figure 7 The shown touch display panel describes the manufacturing method, which includes: the step of forming the first substrate 1 and the step of forming the second substrate 2, wherein:

[0059] The step of forming the first substrate 1 includes: forming a plurality of first signal lines 11 parallel to each other and a plurality of second signal lines 12 parallel to each other, and the first signal lines 11 and the second signal lines 12 are intersected and insulated.

[0060] The step of forming the first substrate 1 further includes: forming a first touch electrode wiring 13 parallel to the first signal line 11 , and sequentially forming an insulating layer 14 and a first touch electrode on the first touch electrode wiring 13 15 , wherein the insulating layer 14 is provided with a via hole 16 corresponding to the first touch electro...

Embodiment 3

[0077] An embodiment of the present invention provides a method for repairing a touch display panel. The touch display panel has the structure in Embodiment 1. It should be emphasized that the first touch electrode 15 and the first touch electrode 15 in the touch display panel The first signal lines 11 adjacent to the first touch electrode traces 13 are partially overlapped, such as Figure 8 and Figure 9 As shown, the repair method includes: if the first signal line is disconnected, cutting the first touch electrode 11 on the outside of the first touch electrode 11 located at the two ends of the first signal line disconnection, and connecting the first touch electrode The overlapping portion of the control electrode 15 and the first signal line 11 is connected to the first signal line 11 .

[0078] Since when the first signal line 11 is disconnected, the first touch electrode trace 13 is cut off outside the first touch electrode 15 located at both ends of the disconnection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com