A single-coil magnetic latching relay

A magnetic latching relay, single-coil technology, applied in electromagnetic relays, relays, electromagnetic relay detailed information and other directions, can solve the problems of glue contamination of the relay itself and the operating platform, difficulty in controlling the dimensional accuracy of parts, and unstable relay parameters. Dispensing operation, accurate dispensing, easy dispensing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

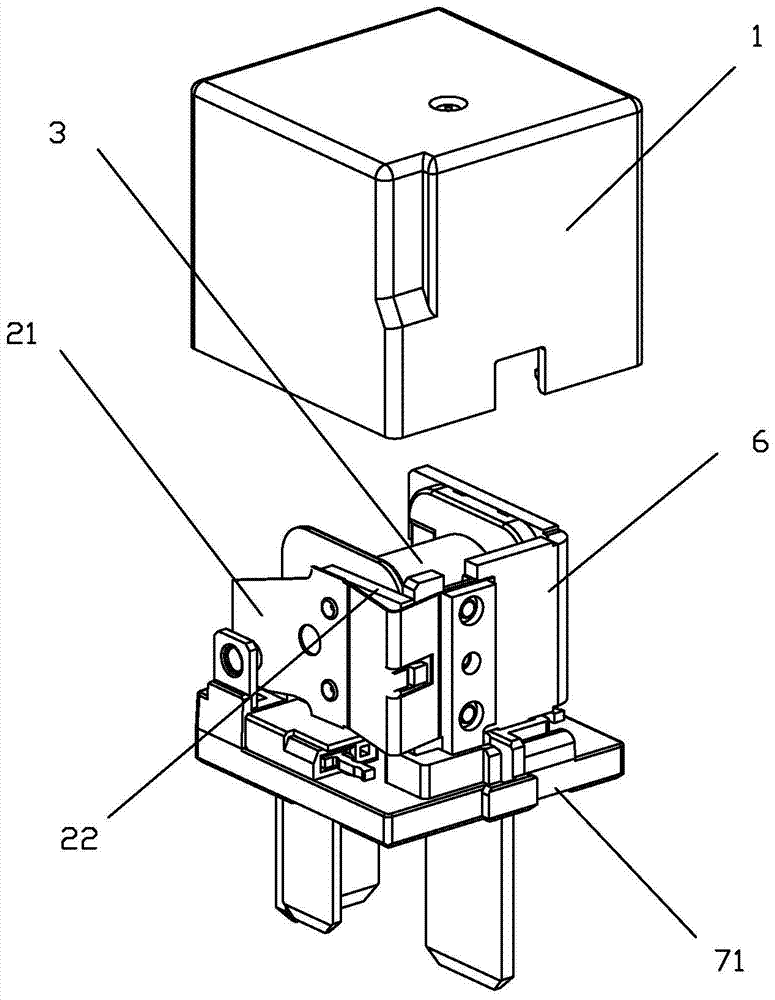

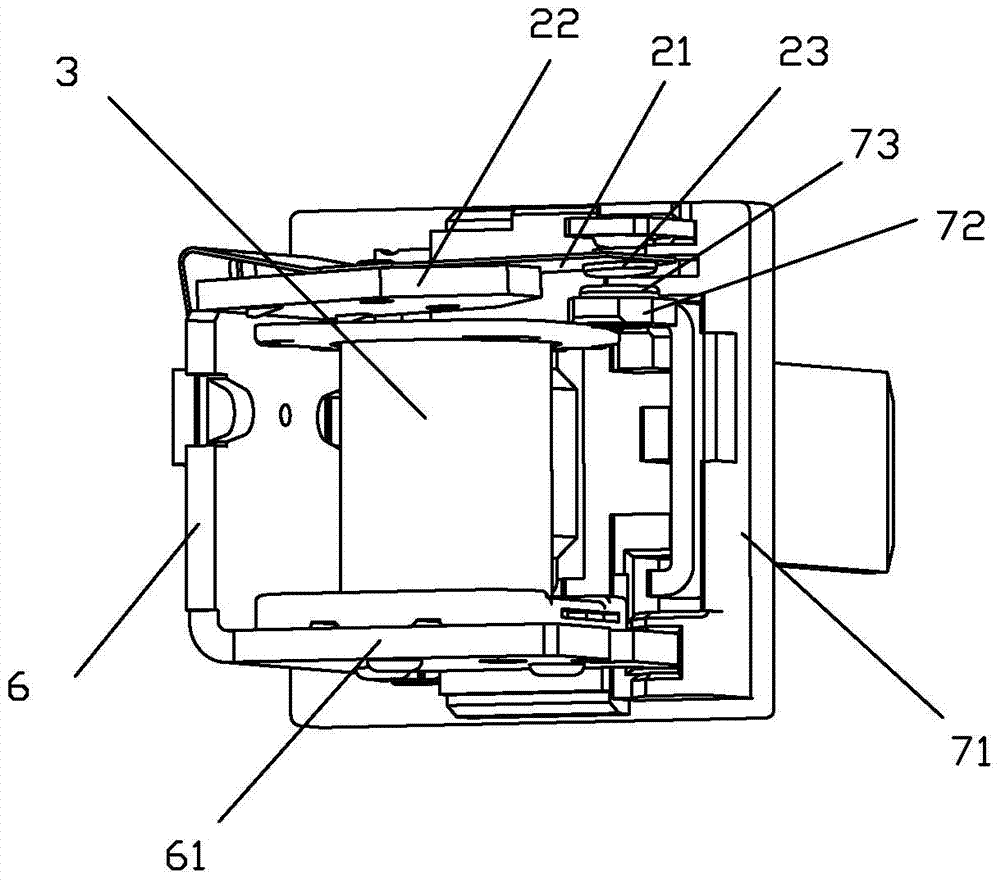

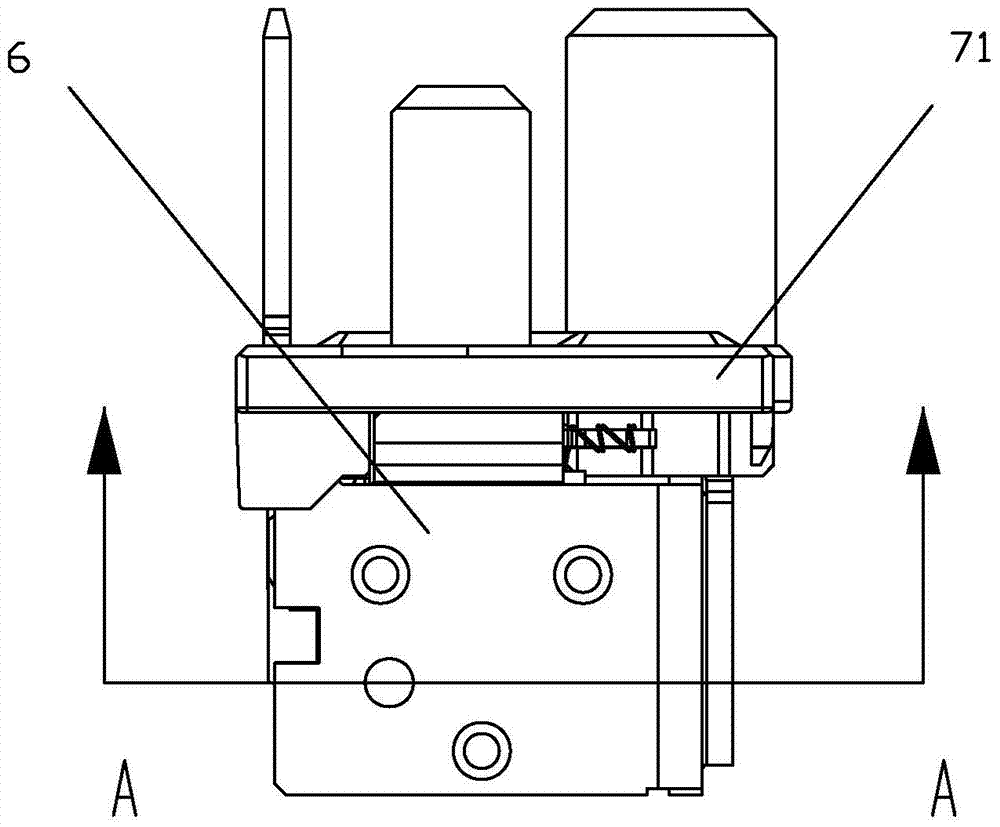

[0025] see Figure 1 to Figure 5 As shown, a single-coil magnetic latching relay of the present invention includes a housing 1, a moving spring armature part, a magnetic circuit part, and a base part; the moving spring armature part includes a moving spring 21, an armature 22, and a moving contact 23; the magnetic circuit part It includes coil frame 3 , magnetic steel 4 , iron core 5 and yoke iron 6 , coil frame 3 is wound with enameled wire; the base part includes base 71 , static spring 72 and static contact 73 . After the magnetic circuit part is assembled with the moving spring armature part, it is loaded into the base part, and then the shell 1 is assembled to form a relay.

[0026] The iron core 5 is inserted into the center hole 31 of the coil frame 3; a groove 32 is provided on the coil frame 3 corresponding to one end of the center hole, the yoke 6 is L-shaped, and one side 61 of the yoke 6 is attached to and fixed on one end of the coil frame 3 provided with a groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com