Solder strip pulling device and method

A technology for welding strips and pressure welding strips is applied in the field of solar cell manufacturing equipment, which can solve the problems of long consumption time of drawing welding strips, affecting the welding efficiency of battery strings, and time-consuming drawing welding strips, etc., so as to improve handling efficiency and improve welding efficiency. Efficiency, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with specific drawings and embodiments.

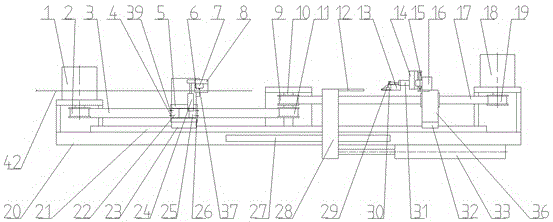

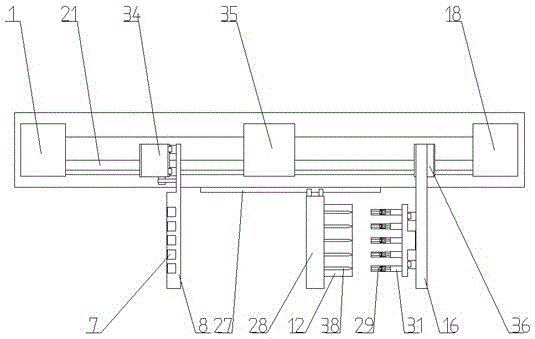

[0023] As shown in the figure, the present invention includes a bottom plate 20, a first line rail 21, a first strip-drawing device, and the first strip-drawing device and the first line rail 21 are respectively installed on the bottom plate 20. After the first strip-drawing device A second strip-drawing device is installed on the side, and a guiding strip device is provided between the first strip-drawing device and the second strip-drawing device, and the guiding strip device includes a guide plate 12, a second line rail 27, a fifth Mounting seat 28, electric cylinder 33, wherein, electric cylinder 33 is fixed on base plate 20, and the output end of electric cylinder 33 connects the 5th mounting seat 28, and the side end of the 5th mounting seat 28 is fixedly set guide plate 12, and guide plate 12 is arranged on the surface There are at least two guide slots ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com