Direct-current charging pile

A technology for DC charging piles and chargers, which is applied in current collectors, electric vehicles, electrical components, etc., can solve the problems of sintering of main circuit control contacts, damage to electric vehicle batteries, and large device loss, and achieve intelligent charging, The effect of protecting against damage, ensuring safety and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with accompanying drawing:

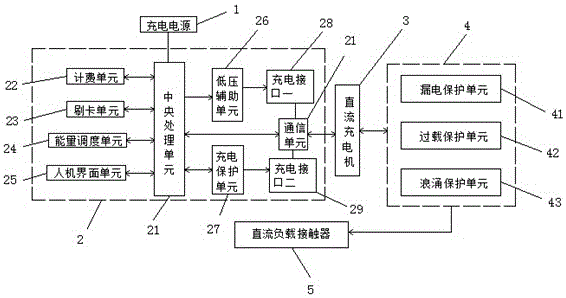

[0009] Such as figure 1 The shown DC charging pile includes a charging power source 1, an intelligent control module 2, a DC charger 3, a main control module 4 and a DC load contactor 5; the intelligent control module 2 includes a central control unit 21, a billing unit 22, Card swiping unit 23, energy scheduling unit 24, man-machine interface unit 25, low-voltage auxiliary unit 26, charging protection unit 27, and at least two charging interfaces, billing unit 22, card swiping unit 23, energy scheduling unit 24, man-machine interface unit 25. The charging protection unit 27 is interactively connected with the central control unit 21, the input terminal of the low-voltage auxiliary unit 26 is connected with the output terminal of the central control unit 21, and its output terminal is connected with the input terminal of the charging interface one 28, and the output termina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com