Composite fiber electric heating twisted yarn and its preparation method

A composite fiber and electric heating technology, applied in the direction of heating element material, heating element shape, etc., can solve the problems of sparks or arcs, heating wires can only be heated, and no physical affinity, etc., and achieve the effect of reducing hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

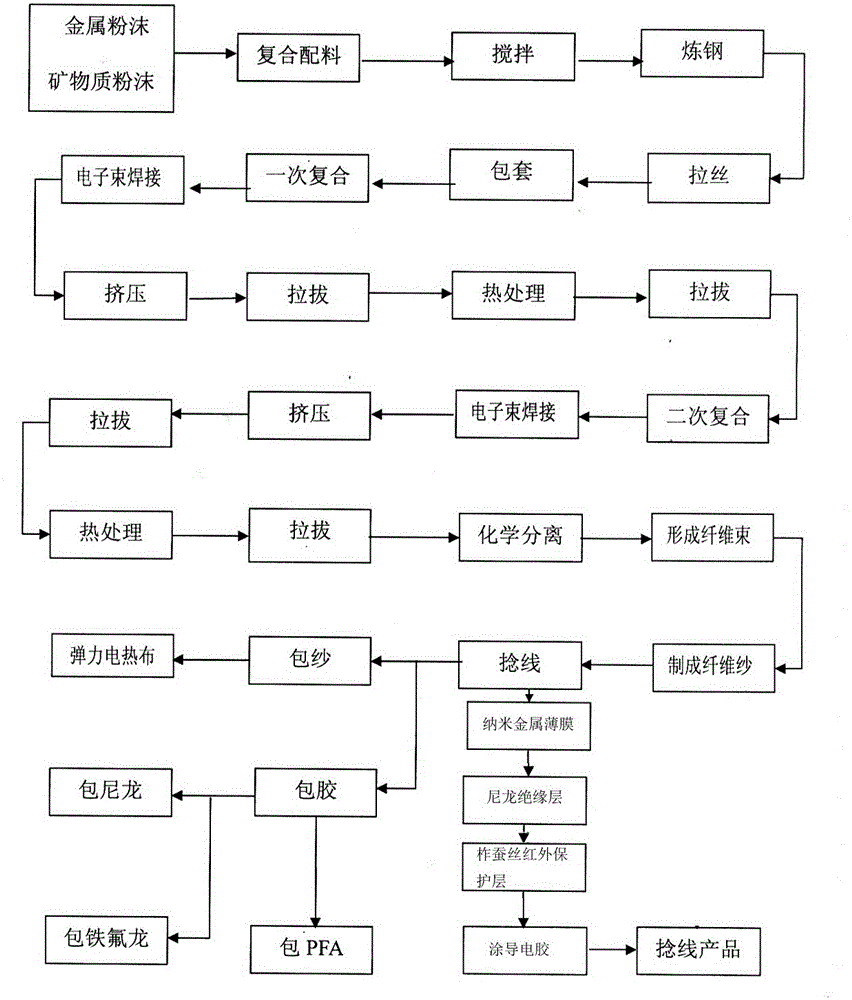

[0035] The specific embodiment: the present invention will be further described below in conjunction with accompanying drawing:

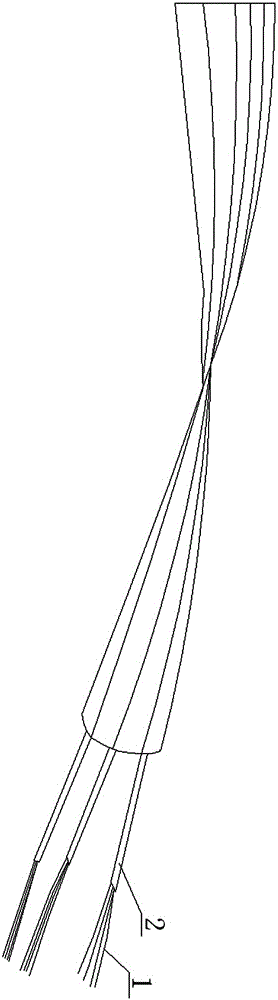

[0036] Such as figure 1 As shown, the present invention provides a composite fiber electrothermal twisted yarn, which is composed of superfine multi-strand composite fiber with a diameter of 7-15um after spinning and twisting. The surface of the superfine composite fiber is not insulated, and it is used for heating at low voltage (below 36V). It can be directly embroidered, corded, quilted, weaved, and cabled. It can also be used as a hand needle and sewing thread, and can work for a long time At 50-120°C.

[0037] The multi-strand composite fiber is 30-15000 strands, and the specific number of strands is selected according to the specific required heating degree.

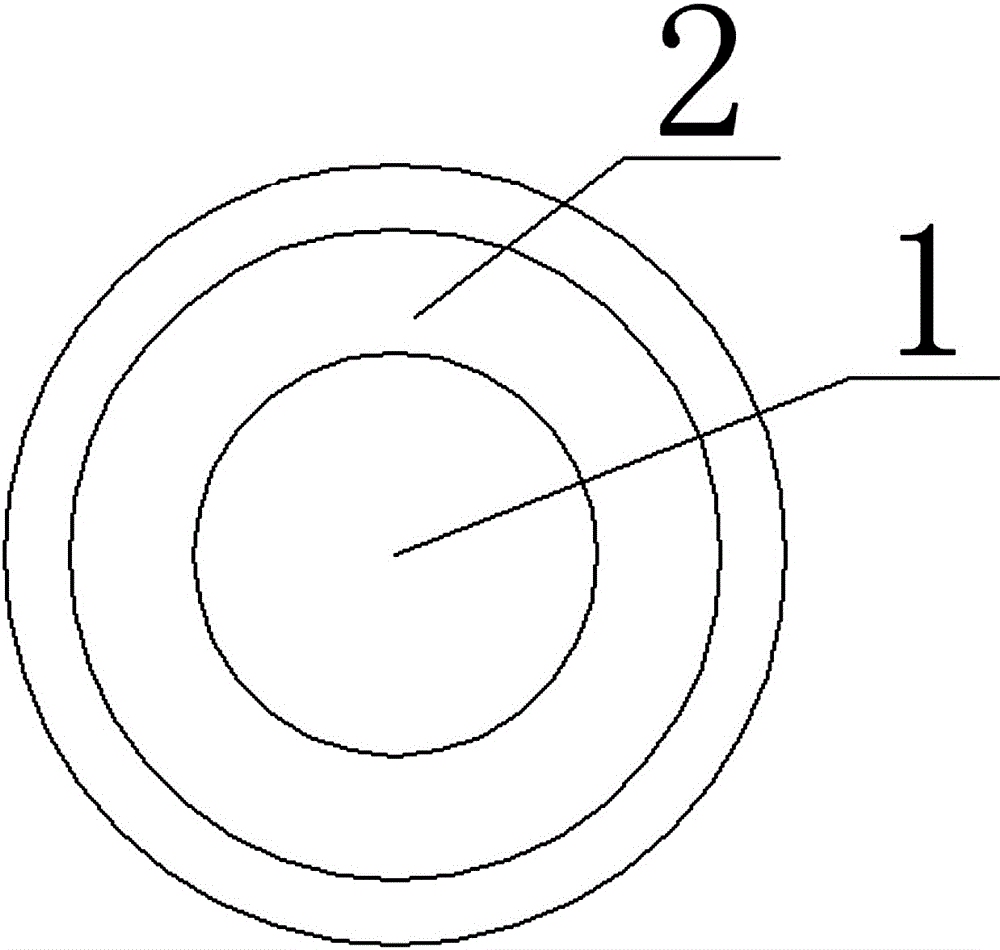

[0038] Such as figure 2 As shown, the nano-metal film 2 is coated on the periphery of the composite fiber 1. When the thickness of the nano-metal film is 2 to 3 microns, the effect i...

Embodiment 1

[0050] (1) Take C: 1.5 parts; Si: 1 part; Mn: 4 parts; Ni: 10 parts; Cr: 17 parts; Mo: 6 parts; W: 2 parts; P: 1 part, pine Skin powder: 3 parts, make compound ingredients, stir well and then use steelmaking method to refine;

[0051] (2) The refined product is wire-drawn, and then the wire-drawn product is successively sheathed and composited, and then electron beam welding is performed to form a primary composite fiber with a diameter of 16um;

[0052] (3) Extruding after electron beam welding, drawing after extrusion, heat treatment, and drawing again, so that the diameter of the primary composite fiber is 13um;

[0053] (4), carry out secondary compounding to the product in (3) step, then carry out electron beam welding, extruding and drawing successively, make the diameter of primary composite fiber be 10um;

[0054] (5) Carry out heat treatment to the product in the "(4)" step, draw after the heat treatment, and form ultrafine fiber bundles with a diameter of 9um after ...

Embodiment 2

[0057] (1) Take C: 2.5 parts; Si: 2.5 parts; Mn: 3 parts; Ni: 13 parts; Cr: 15 parts; Mo: 3 parts; W: 3 parts; The compound ingredients are mixed evenly and refined by steelmaking method;

[0058] (2) The refined product is subjected to wire drawing treatment, and then the drawn product is sequentially sheathed and composited, and then electron beam welding is performed to form a primary composite fiber with a diameter of 40um;

[0059] (3) Extruding after electron beam welding, drawing after extrusion, heat treatment, and drawing again, so that the diameter of the primary composite fiber is 30um;

[0060] (4), carry out secondary compounding to the product in (3) step, then carry out electron beam welding, extrusion and drawing successively, make the diameter of primary composite fiber be 25um;

[0061] (5) Carry out heat treatment to the product in the "(4)" step, draw after the heat treatment, and form ultrafine fiber bundles with a diameter of 20um after chemical separati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com