Efficient and safe tubular bus static contact

A technology of tube busbar and static contact, which is applied in the direction of fully enclosed busbar device, busbar installation, cable installation, etc., can solve the problems of not meeting the performance requirements of parts, reducing service life and reliability, and high contact resistance, etc. Achieve the effect of ensuring safe operation, reliable operation and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

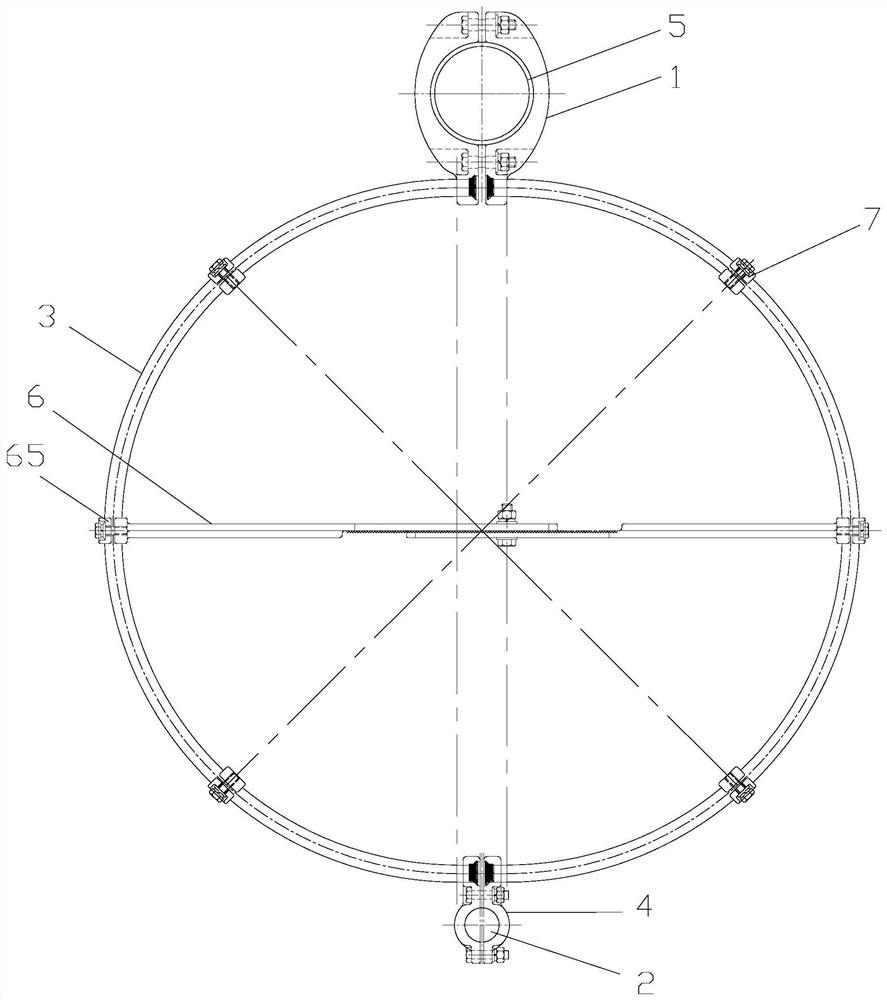

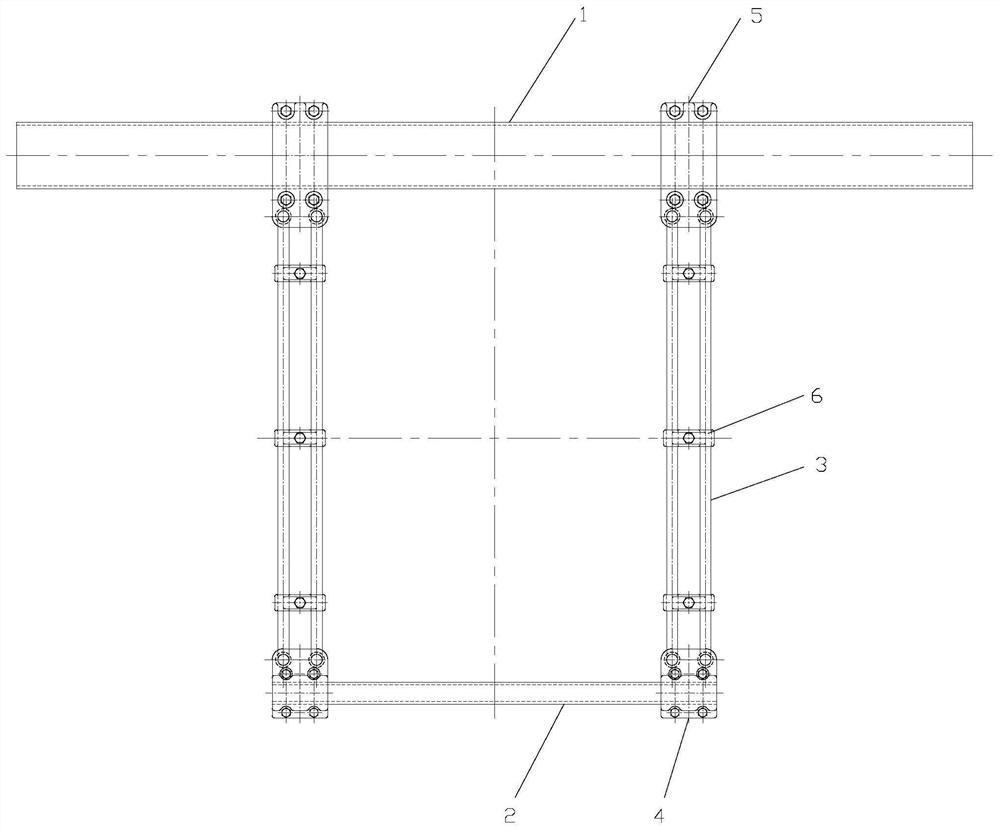

[0045] The present invention as Figure 1-10 As shown, it includes a pipe busbar 1, and also includes a copper pipe 2, two annular conductor coils 3, two copper pipe holding clips 4 and two busbar holding clips 5,

[0046] The pipe busbar 1 is connected in two busbar holding clips 5,

[0047] The copper tube 2 is connected in two copper tube clamps 4,

[0048] The busbar holding clip 5, the annular conductive coil 3 and the copper pipe holding clip 4 correspond to each other respectively, and the annular conductive coil is located between the busbar holding clip and the copper pipe holding clip;

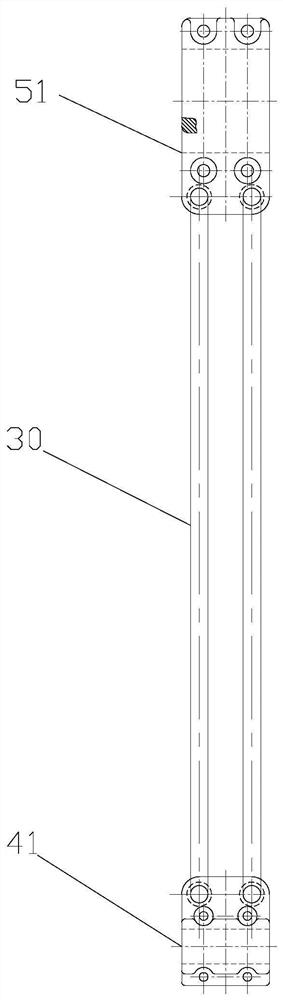

[0049] The annular conductor coil 3 includes a pair of symmetrical semicircular conductors 30, the bottom of the busbar holding clip 5 is provided with a symmetrically arranged sink hole 50, and the top of the copper pipe holding clip 4 is provided with a symmetrically arranged upper The counterbore 40 , the two ends of the semicircular wire 30 are welded in the sink hole 50 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com