Simple sowing pipe

A seeding pipe and simple technology, applied in the field of seeding pipe, can solve the problems of waste of tunnels, high labor intensity, low seeding efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

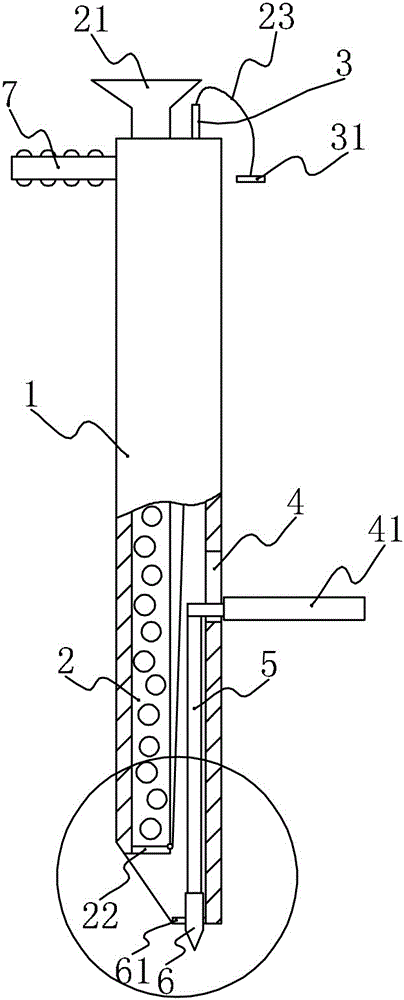

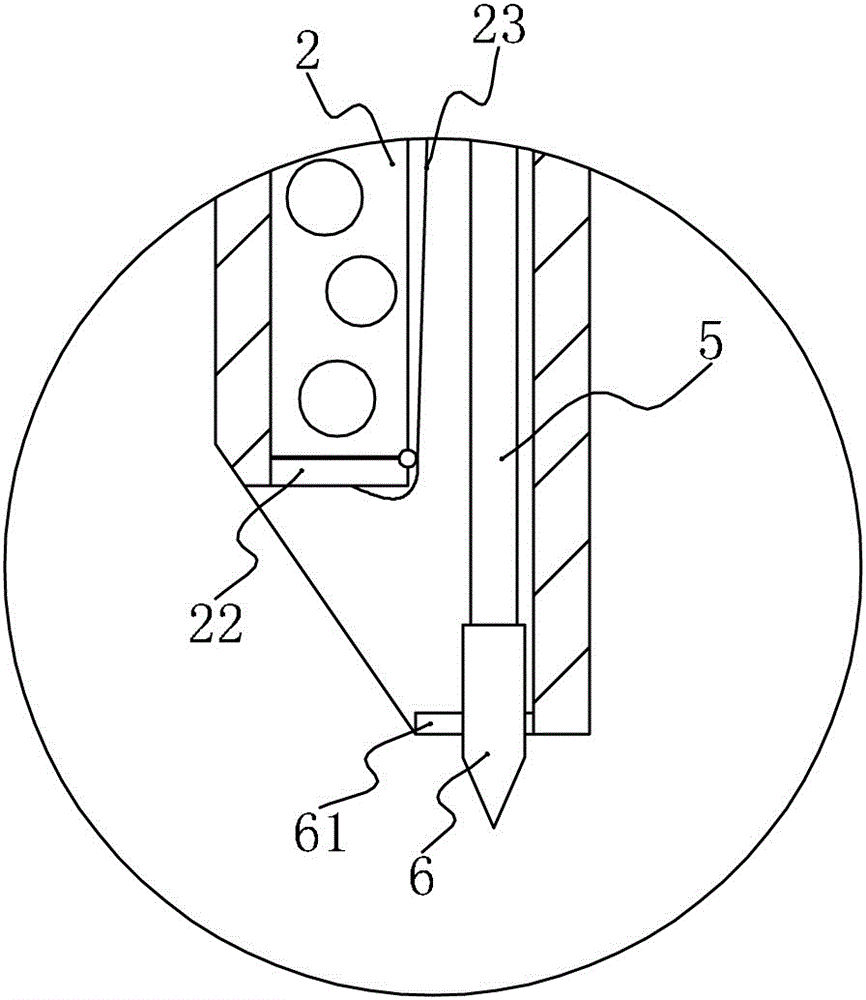

[0017] like figure 1 and figure 2 As shown, the simple seeding pipe of the present invention includes a vertical pipe body 1 , the lower end of which is tapered, and a circular nozzle is opened on the lower end surface of pipe body 1 . There is a cavity inside the tube body 1, and a material tube 2 for placing seeds is fixed in the cavity, and a funnel mouth 21 is formed at the upper end of the material tube 2, and seeds can be added into the material tube 2 from the funnel mouth 21. A baffle plate 22 is hinged at the lower end of the material tube 2, and a torsion spring is installed on the rotating shaft of the baffle plate 22, and the effect of the torsion spring is to control the lower port of the baffle plate 22 to seal the material tube 2 under normal conditions. In addition, in order to be able to open the baffle 22, a stay rope 23 is fixedly connected to the baffle 22, the stay rope 23 goes around the rotating shaft of the baffle 22, and the baffle 22 can be pulled b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com