Production process for preparing pickled cowpeas through fermentation with pickle water

A production process, kimchi water technology, applied in the direction of bacteria used in food preparation, application, food science, etc., can solve the problems of unfavorable economic benefits of enterprises, high processing costs, waste of water resources, etc., to make up for flavor defects and improve enterprise Benefits, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

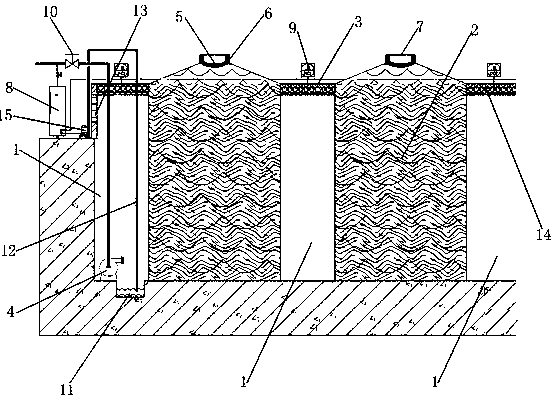

Image

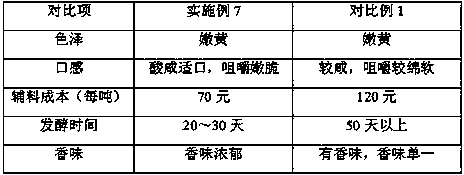

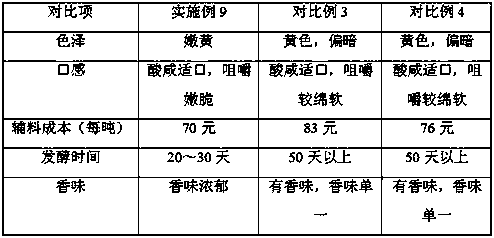

Examples

Embodiment 1

[0049] This example proposes a production process for preparing soaked cowpea by fermenting pickle water. The production process is to add cowpea, salt, pickle water and lactic acid bacteria preparations to the fermenter, and then prepare soaked cowpea through sealing and heat preservation fermentation. It solves the current production status of the traditional soaked cowpea with weak flavor, high salt and nitrite content, inconvenient management and low safety performance.

[0050] In the above-mentioned production process, cowpea adopts fresh cowpea after washing. The pickle water is obtained by pretreatment of pickle pickling water. The lactic acid bacteria preparation includes the following components by weight percentage: Lactobacillus plantarum powder 15.00% (the viable count of Lactobacillus plantarum powder meets 1.0×10 10 ~1.0×10 11 CFU / g), Lactobacillus acidophilus powder 20.00% (the viable count of Lactobacillus acidophilus powder reaches 1.0×10 9 ~1.0×10 10 CFU...

Embodiment 2

[0052] This example proposes a production process for preparing soaked cowpea by fermenting pickle water. The production process is to add cowpea, salt, pickle water and lactic acid bacteria preparations to the fermenter, and then prepare soaked cowpea through sealing and heat preservation fermentation. It solves the current production status of the traditional soaked cowpea with weak flavor, high salt and nitrite content, inconvenient management and low safety performance.

[0053] In the above-mentioned production process, cowpea adopts fresh cowpea after washing. The pickle water is obtained by pretreatment of pickle pickling water. The lactic acid bacteria preparation includes the following components by weight percentage: 25.00% of plantarum lactobacillus powder (the number of live bacteria of plantaractobacillus powder meets 1.0×10 10 ~1.0×10 11 CFU / g), Lactobacillus acidophilus powder 10.00% (the viable count of Lactobacillus acidophilus powder reaches 1.0×10 9 ~1.0×...

Embodiment 3

[0055] This example proposes a production process for preparing soaked cowpea by fermenting pickle water. The production process is to add cowpea, salt, pickle water and lactic acid bacteria preparations to the fermenter, and then prepare soaked cowpea through sealing and heat preservation fermentation. It solves the current production status of the traditional soaked cowpea with weak flavor, high salt and nitrite content, inconvenient management and low safety performance.

[0056] During the above production process,

[0057] (1) Fresh cowpea after washing is used for cowpea.

[0058] (2) The amount of salt added is 8% of the amount of cowpea added in the fermenter.

[0059] (3) Pickle water is obtained by pretreatment of pickle water, and the technical indicators of the pickle water meet: total acid content 0.50%, salt content 10.00%, salt-free solid content 0.80%, protein 0.05%, microorganism 10cfu / mL, acrylamide 0.10ug / L.

[0060] The preprocessing steps are as follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com