Method for preparing sweet sorghum solid beverage by utilizing constant low temperature fermentation method

A low-temperature fermentation and solid beverage technology, which is applied in the field of drinking product processing, can solve the problems of insufficient fermenting bacteria activity, changes in color and flavor, poor low-temperature fermentation effect, etc., and achieves the effects of being beneficial to physiological activities, having a pure taste, and accelerating the fermentation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

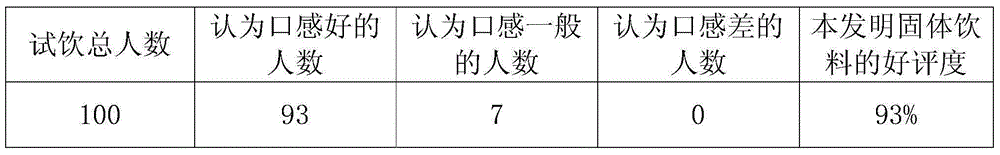

Examples

Embodiment 1

[0033] A pineapple-flavored sweet sorghum solid beverage, the raw material components of which are: 100kg of sweet sorghum, 25kg of sugarcane, 4.5kg of eucommia leaves, 0.5kg of pineapple essence, 0.3kg of a thickener, and 0.2kg of a foaming agent.

[0034] The preparation method is as follows:

[0035] 1) Raw material pretreatment and constant low temperature fermentation

[0036] 1. After crushing the sugarcane, sweet sorghum, and eucommia leaves of said parts by weight, add 4kg of salt water to make a paste, then import it into a blender and stir for 2 to 5 hours to obtain a paste mixture A. After adjusting by salt water, Due to free diffusion, the water in the cell penetrates to the outside of the cell, the concentration of the saline is 0.5-0.9mol / L, and the temperature is 7-10°C;

[0037]② Add 1-5°C alcohol solution to the mixture A, and mix and stir for 8-20 hours at a constant temperature of 5-10°C to obtain a pasty mixture B. The mass concentration of the alcohol sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com