Alcohol group fuel tobacco curing house

An alcohol-based fuel and flue-cured tobacco room technology, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of inconvenience in hanging and collecting tobacco leaves, low effective utilization rate of heat energy, and inability to adjust the tobacco hanging rack, so as to save electricity. The effect of increasing the flue gas circulation speed and shortening the air supply distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

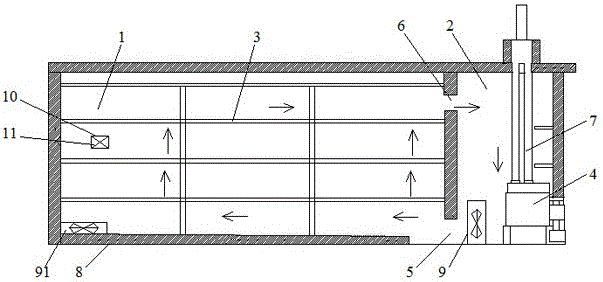

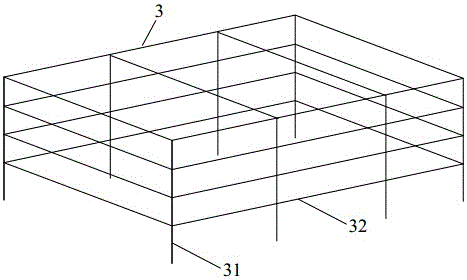

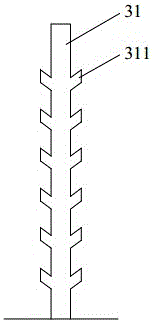

[0025] The accompanying drawings are for illustrative purposes only, and should not be construed as limitations on this patent; in order to better illustrate this embodiment, certain components in the accompanying drawings will be omitted, enlarged or reduced, and do not represent the size of the actual product; for those skilled in the art It is understandable that some well-known structures and descriptions thereof may be omitted in the drawings. The positional relationship described in the drawings is for illustrative purposes only, and should not be construed as a limitation on this patent.

[0026] Such as figure 1 As shown in -3, a flue-cured tobacco room for alcohol-based fuel, which includes a hot air chamber 2 equipped with a heating device 4, a flue-cured tobacco room 1 equipped with a tobacco rack 3, and an air inlet between the flue-cured room 1 and the hot air chamber 2 5 and the air return port 6 form a circulating flue, and the heating device 4 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com