Selective laser melting technology-based pure titanium orthodontic bracket and making method thereof

A technology of orthodontic brackets and laser melting, applied in the direction of brackets, can solve problems such as uneven dentition and inability to match the oral cavity well, and achieve the effects of reducing powder consumption, shortening development time, and good curative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

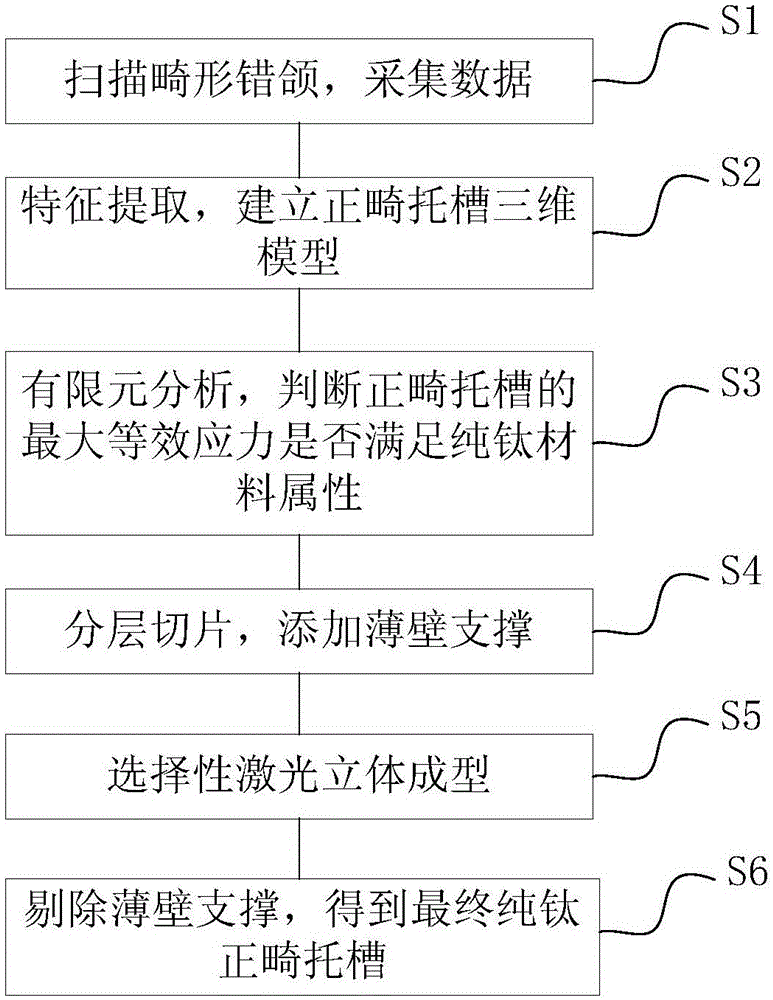

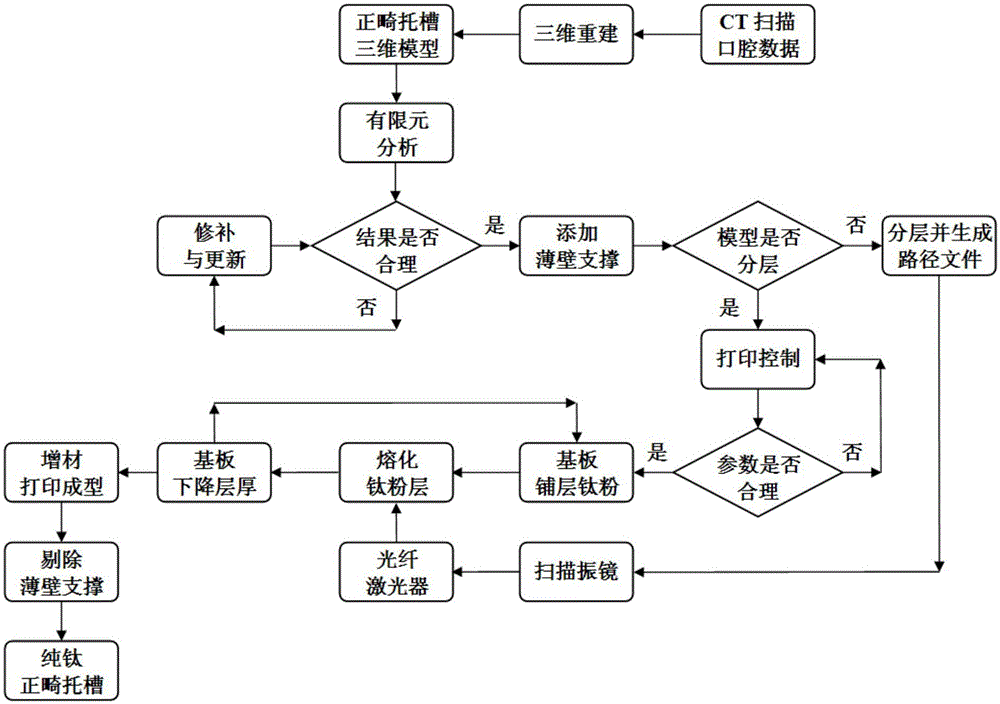

[0028] figure 1 with figure 2 A flow chart of a pure titanium orthodontic bracket based on selective laser melting technology and a manufacturing method thereof according to the present invention is shown, including the following steps:

[0029] S1. Perform CT scan on malocclusion to obtain three-dimensional data of jaws, teeth, etc.;

[0030] S2. Eliminate noise points through reverse engineering, and perform feature extraction and 3D reconstruction to obtain a 3D model of orthodontic brackets;

[0031] S3. Use finite element analysis technology to analyze the results of the maximum equivalent stress of orthodontic brackets, and judge whether they meet the properties of pure titanium materials under the double safety factor; The 3D model is repaired and updated to meet the conditions; if the conditions are met, enter the next step;

[0032] S4. Save the 3D model of the orthodontic bracket that needs to be printed, add thin-wall support to the 3D model of the orthodontic b...

Embodiment 2

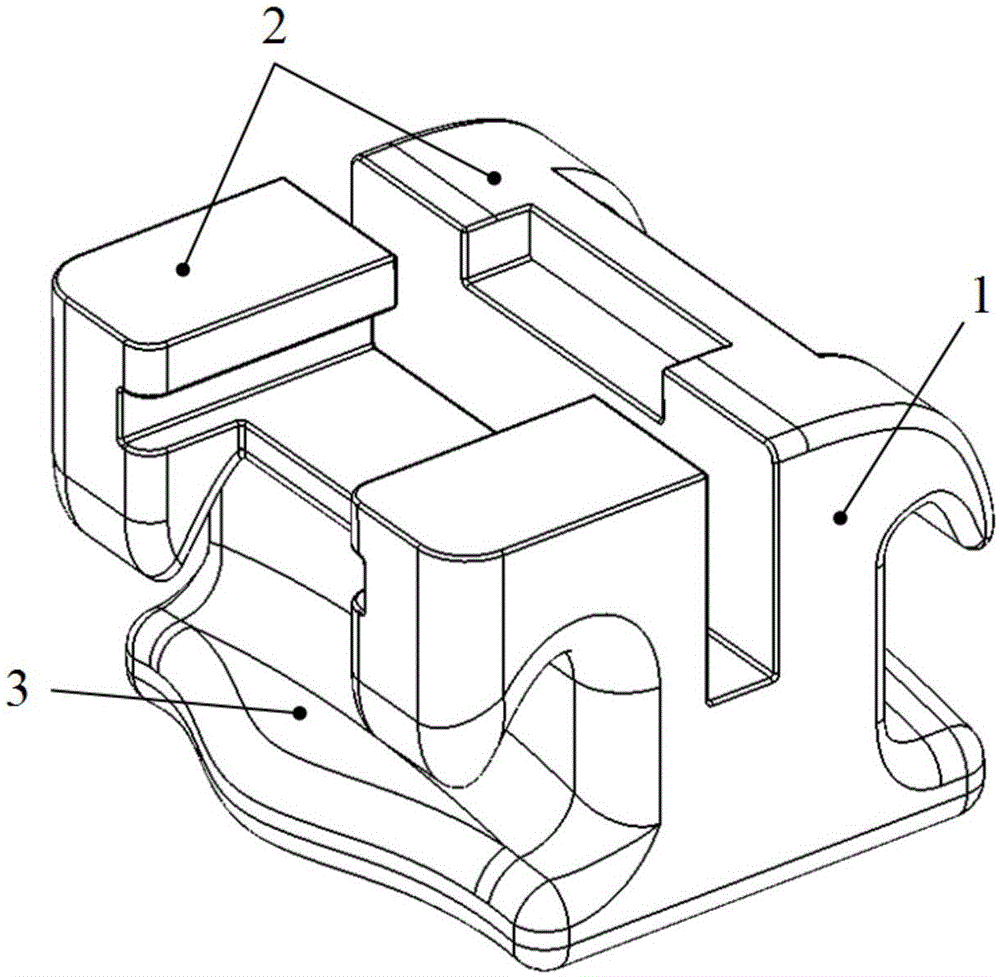

[0041] image 3 Shown is a pure titanium orthodontic bracket based on selective laser melting technology, including a tank body 1, a working wing 2, and a base plate 3, and its pure titanium orthodontic bracket is manufactured according to the method in Example 1 .

[0042]To sum up, the beneficial effects of the present invention are: adopting advanced computer-aided design, combined with medical imaging technology CT and high-precision selective laser three-dimensional forming technology, oral examination, structural design of orthodontic brackets, finite element analysis , selective laser three-dimensional molding, etc., to design the most suitable personalized pure titanium orthodontic self-ligating bracket for each patient according to the different oral conditions of each patient, which brings good news to the rehabilitation of patients and can greatly shorten the time for new products. Development time;

[0043] The direct additive molding of pure titanium orthodontic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com