Flue dust remover for biomass energy boiler

A boiler flue and biomass energy technology, applied in chemical instruments and methods, dispersed particle separation, combined devices, etc., can solve the problems of limited blocking effect, reduce the passing rate of flue gas, etc., achieve extended service life, simple structure, easy-to-manufacture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

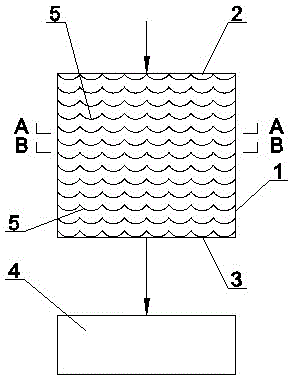

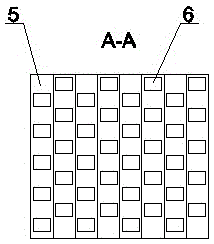

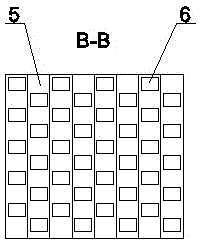

[0016] Such as figure 1 , figure 2 and image 3 As shown, a biomass boiler flue dust collector of the present invention includes a housing 1 arranged in the flue, the housing 1 is provided with an air inlet 2 and an air outlet 3, and the inner edge of the housing 1 is A plurality of rows of dust-shielding plates 5 are provided in the flow direction of the flue gas. The dust-shielding plates 5 are provided with through holes 6 staggered along the vertical and horizontal directions, and the dust-shielding plates 5 at adjacent positions are placed in a staggered arrangement of the through-holes 6 .

[0017] The dust shield 5 is wave-shaped, and its troughs face the direction of flue gas flow.

[0018] Thirteen rows of dust baffles 5 are arranged inside the housing 1 along the flow direction of the flue gas.

[0019] A biomass boiler flue dust collector of the present invention, in the shell 1 of the flue, a plurality of rows of dust baffles 5 are arranged along the flow direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com