A device and method for expanding single output of diamond synthesis

A diamond and yield technology is applied in the field of devices for improving synthesis efficiency and synthesis quality in the synthesis process of superhard materials, and can solve the problems of reducing the synthesis benefit of a single block, affecting the safety of diamonds, affecting the synthesis efficiency, etc., and improving the synthesis efficiency of diamonds. , to avoid the air bubble accident, the effect of saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

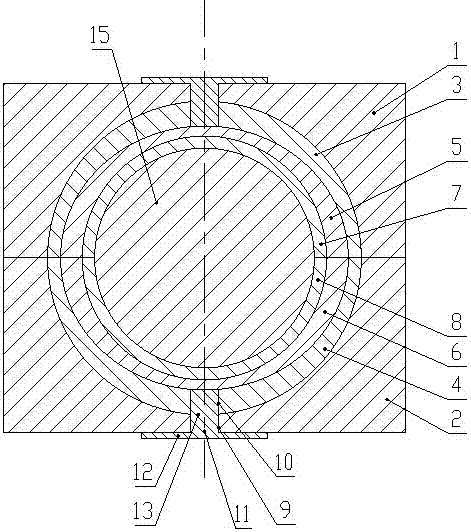

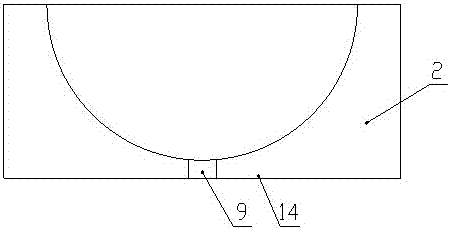

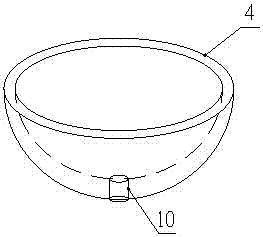

[0028] Such as figure 1 As shown, the device of the present invention includes a conductive ring 11 and a seat body, an outer-lined heat preservation bowl, a graphite bowl, an inner liner heat-resistance bowl, and graphite balls 15 that are sequentially wrapped from outside to inside. The shapes of the adjacent contact surfaces between the seat body, the outer lining insulation bowl, the graphite bowl, the inner lining insulation bowl, and the graphite ball 15 are compatible, and there is no spacing between the contact surfaces. Graphite ball 15 is spherical, and material is graphite. The seat body, the outer lining heat preservation bowl, the graphite bowl, and the inner lining heat preservation bowl all have the structure of upper and lower split bodies, which are divided into two parts, the upper and lower parts have the same shape. The openings of the upper and lower outer-lined insulation bowls, the graphite bowl, and the inner-lined insulation bowl are buckled to form a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com