A continuous moving magnetic pole vibrating bed high gradient permanent magnet magnetic separator

A vibrating bed and high-gradient technology, applied in the field of magnetic separation, can solve the problems that it cannot be used in water-deficient areas, cannot be separated by magnetic materials with different magnetic properties, and is not worth promoting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Below, the technical solution of the present invention will be described in detail through specific examples.

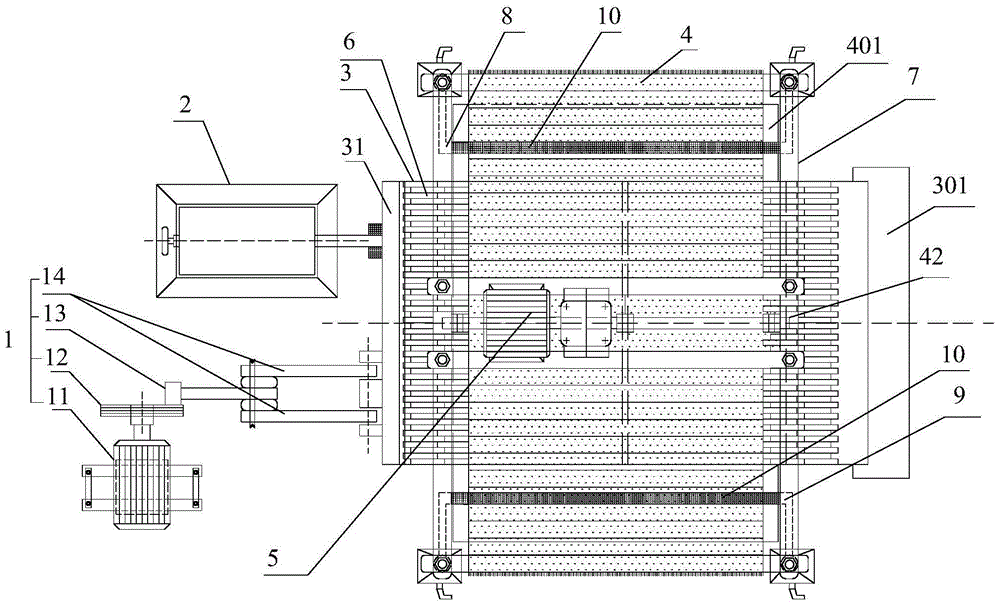

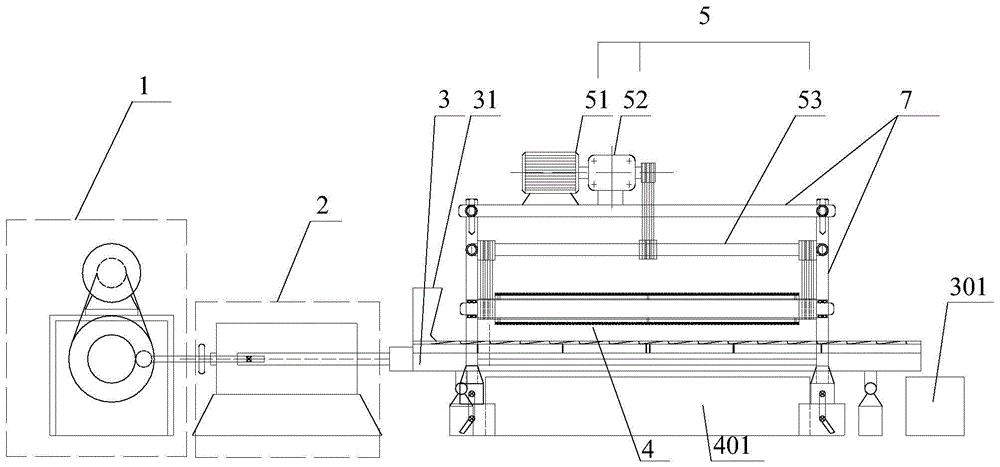

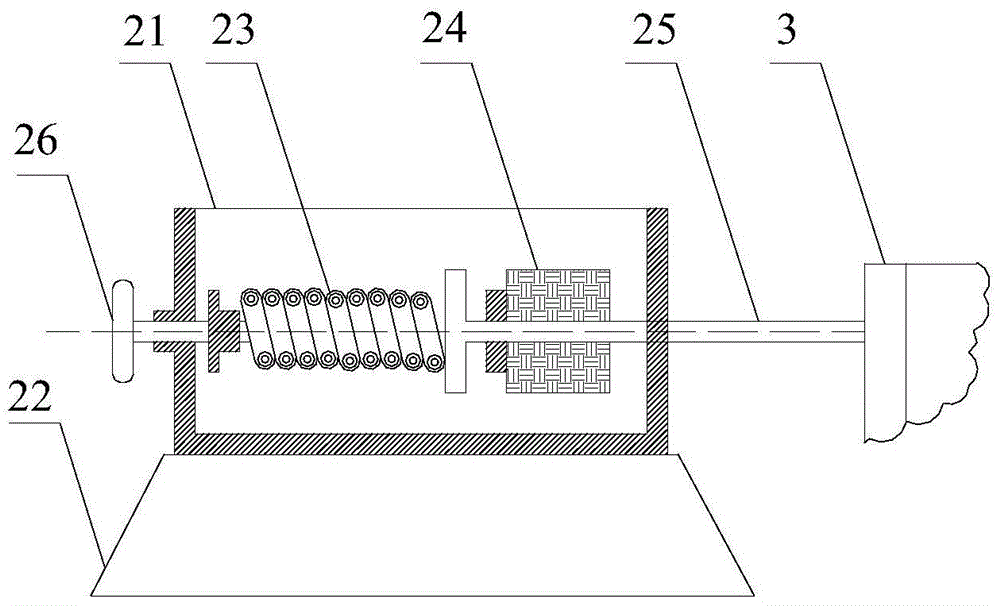

[0056] Such as Figure 1-11 as shown, figure 1 It is a structural schematic diagram of a continuous moving magnetic pole vibrating bed high-gradient permanent magnet magnetic separator proposed by the present invention; figure 2 A side view of a continuous moving magnetic pole vibrating bed high gradient permanent magnet magnetic separator proposed by the present invention; image 3 It is a structural schematic diagram of the differential structure described in a continuous moving magnetic pole vibrating bed high-gradient permanent magnet magnetic separator proposed by the present invention; Figure 4 It is a structural schematic diagram of the bed body in the high-gradient permanent magnet magnetic separator of a continuous moving magnetic pole vibrating bed proposed by the present invention; Figure 5 It is a structural schematic diagram of the wedge des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com