Method for machining middle die body of bending machine die for round workpieces

A circular workpiece and mold processing technology, which is applied in the field of mold processing of bending machine molds, can solve problems such as inability to process circular errors, and achieve improved hardness and wear resistance, improved wear resistance, and high hardness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

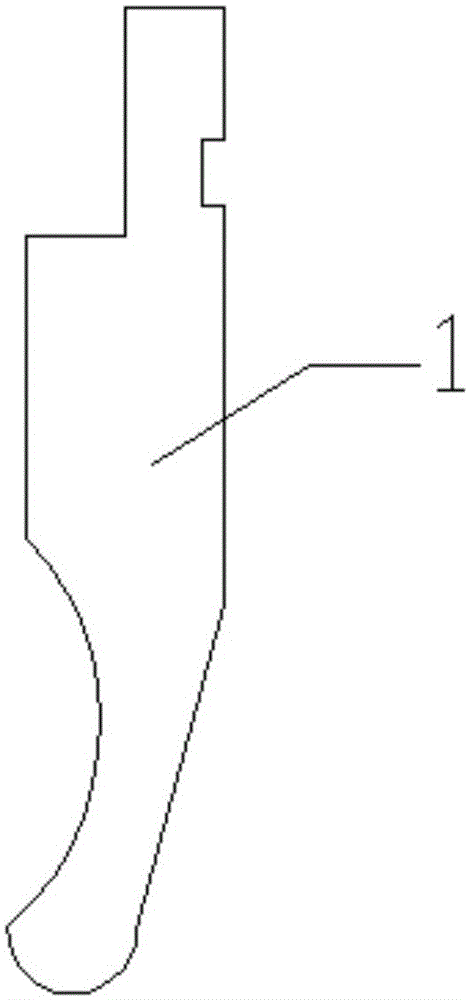

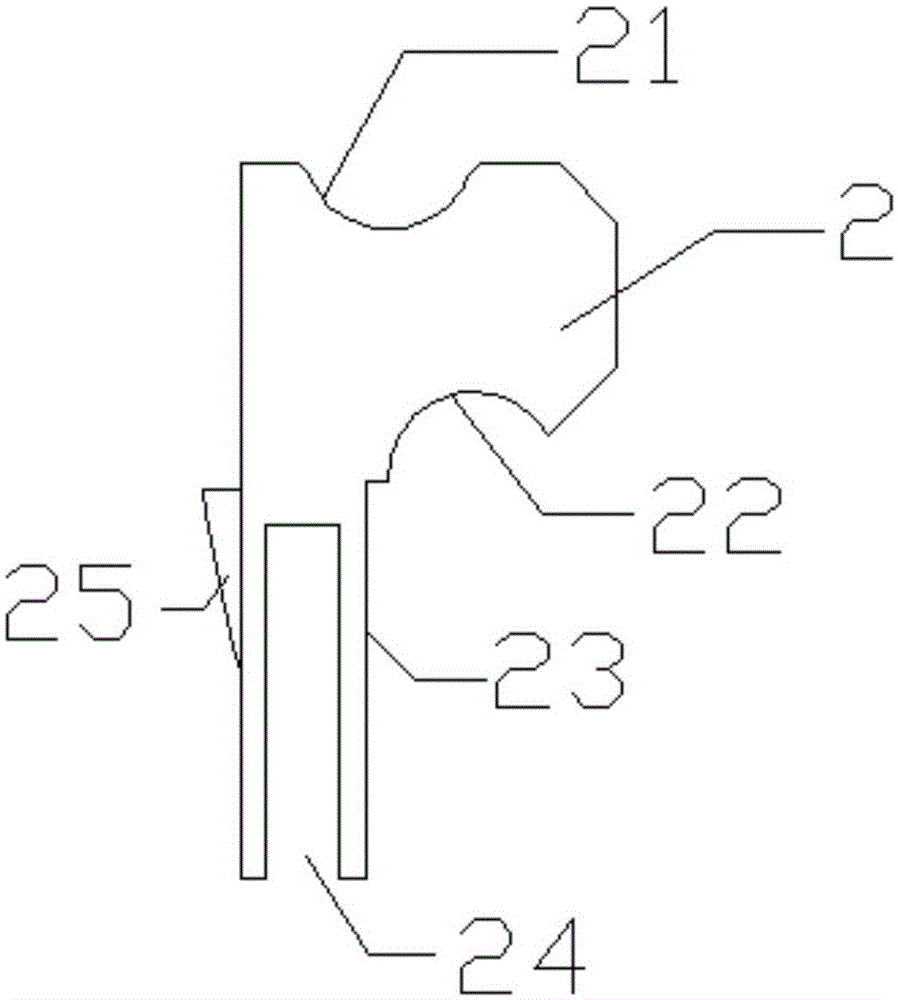

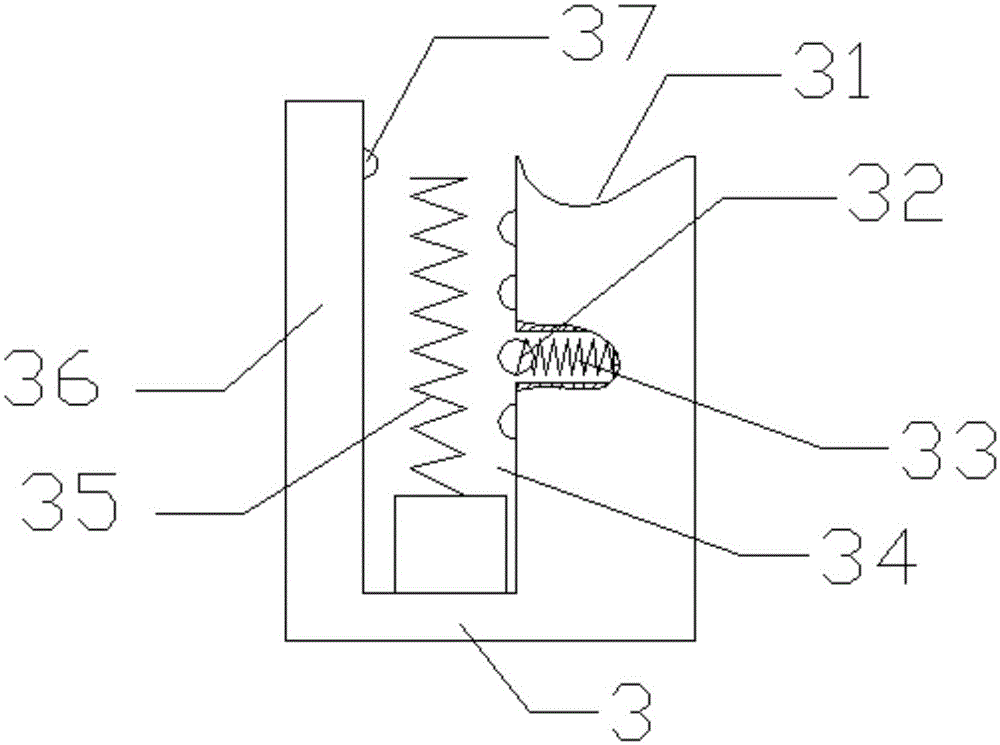

[0043] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 and Figure 7 As shown, a bending machine mold for a circular workpiece includes an upper mold 1, a middle mold 2 and a lower mold 3, the lower surface of the upper mold 1 is arc-shaped; the middle mold 2 is divided into upper and lower molds. part and the lower part 23 of the middle mold; the upper part of the upper part of the middle mold is provided with a downward concave first arc groove 21, and the first arc groove 21 is semicircular; the left side below the upper part of the middle mold is The lower part 23 of the middle mold, the right side below the upper part of the middle mold is provided with an upwardly concave second arc groove 22; the middle part of the middle mold lower part 23 is provided with a vertically upwardly concave first spring groove 24; the left side of the lower part 23 of the middle mold is provided with an arc-shaped protrusion 25; the middle part of the lower mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com