Device and method for detecting height position of working face of 3D printing platform

A 3D printing and detection device technology, applied in the direction of additive processing, etc., can solve the problems of low positioning accuracy of mechanical switches, difficult starting layer height position, difficult adjustment of mechanical switch positions, etc., to offset errors and achieve accurate and reliable position detection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

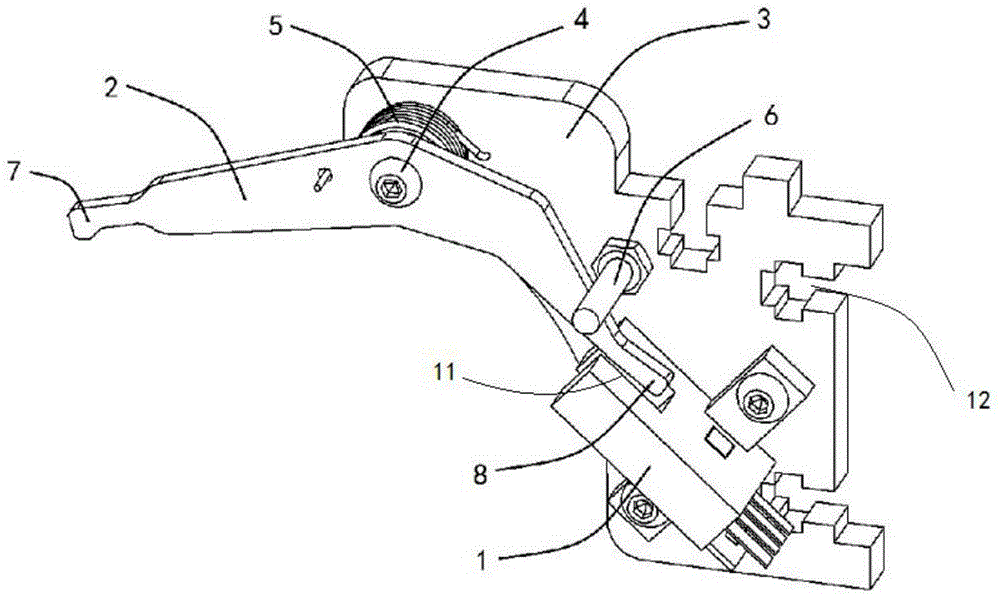

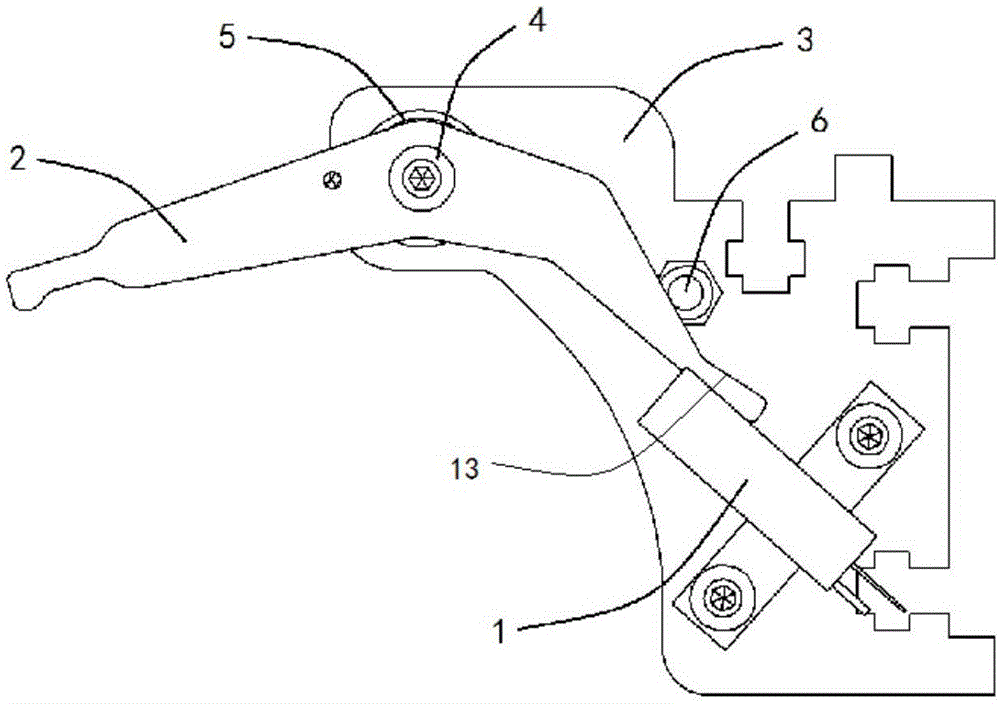

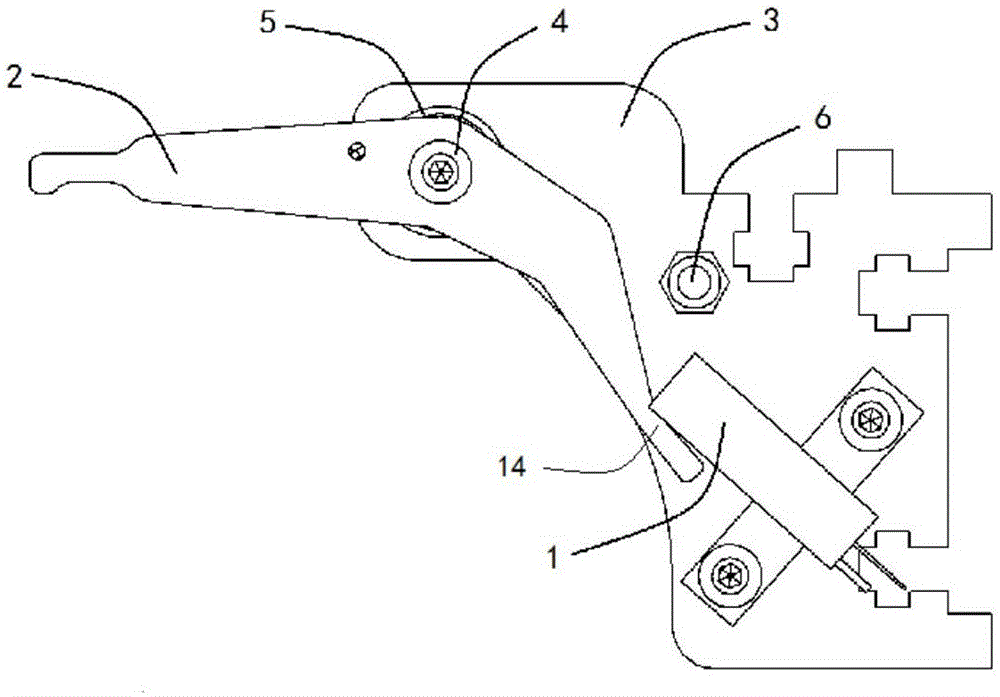

Embodiment 1

[0027] Such as Figures 1 to 2 As shown, a height position detection device for the working surface of a 3D printing platform provided by the present invention is specifically described, including a base plate 3 provided with a limit post 6 at the middle position, the base plate 3 is provided with a rotating shaft 4 and a photoelectric sensor 1, and the The rotating shaft 4 is connected to the cantilever 2 that rotates around its axis, and the sensing end 8 of the cantilever 2 is arranged in the photoelectric sensing area 11 of the photoelectric sensor 1 and can be between the first working position 13 and the second working position 14 Do reciprocating movement, the sensing end 8 is arranged under the limit post 6, the detection end 7 of the cantilever 2 moves up and down around the axis of the rotating shaft 4, and one side of the substrate 3 is provided with a 3D printer connected Mounting groove 12, the preferred photoelectric switch of described photoelectric sensor 1, th...

Embodiment 2

[0036] On the basis of Embodiment 1, the present invention also provides a detection method using a height position detection device on the working surface of the 3D printing platform. The difference from Embodiment 1 is that step 2) can also adopt the following methods. The steps are the same. The step 2) is to raise the working surface 9 of the 3D printing platform to contact with the detection end 7 of the cantilever 2, and continue to raise the working surface 9 of the 3D printing platform, so that the sensing end 8 of the cantilever 2 enters the photoelectric The sensing area 11 of the sensor 1, and trigger the photoelectric sensor 1, then the working surface 9 of the 3D printing platform changes direction from rising to falling, and close the electric sensor 1, the height at this time is h1, and then the 3D printing platform 9 is Decline and change direction to rise, so that the sensing end 8 of the cantilever 2 enters the sensing area 11 of the photoelectric sensor 1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com