Bagging mechanism for bagging machine

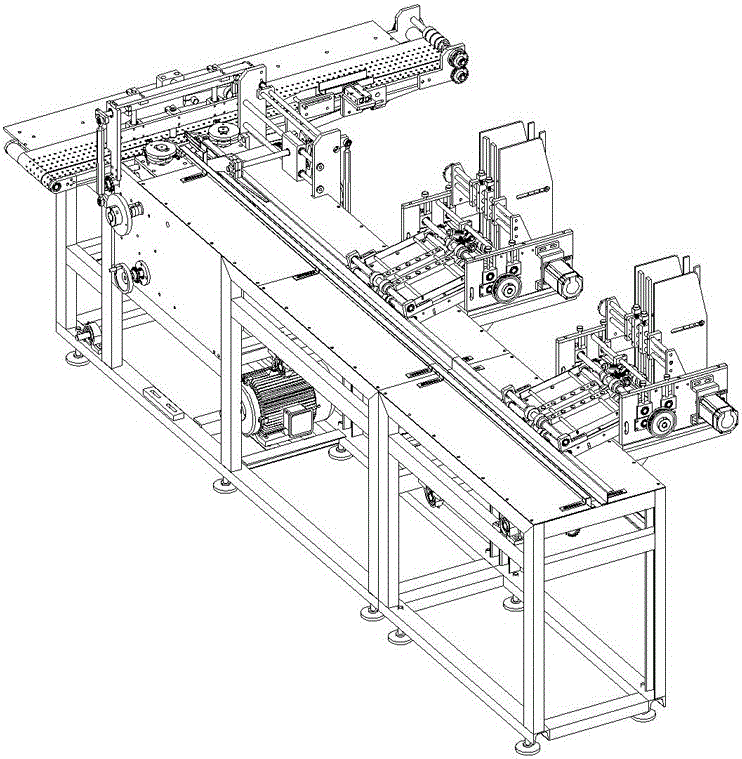

A machine bagging and bag clamping technology is applied in the field of bagging mechanism of bagging machines, which can solve the problems of inability to carry out bagging work smoothly, limited production speed design, complicated structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

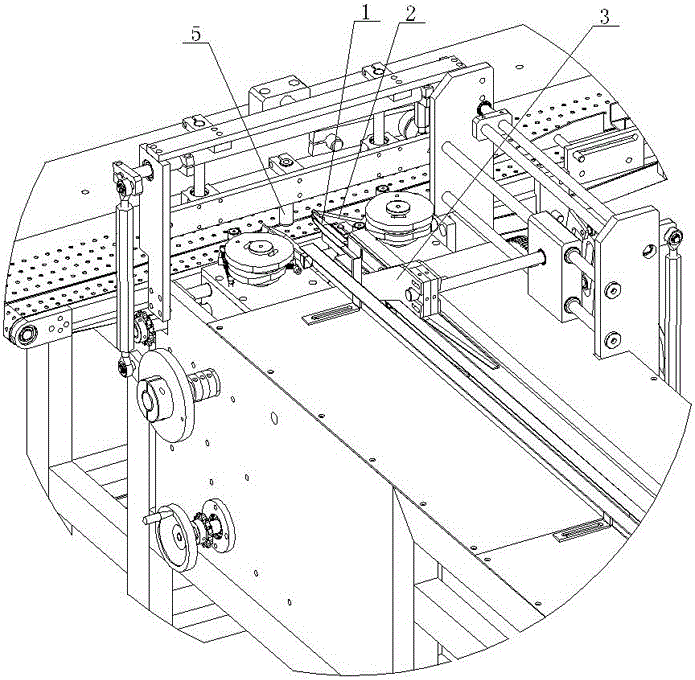

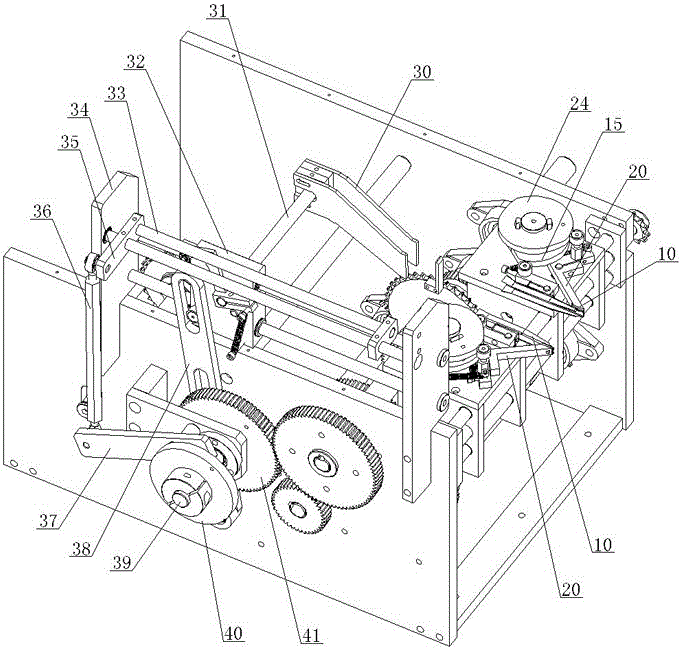

[0017] The accompanying drawings represent the technical solutions of the present invention, and the relevant details and working principles of the examples are further described below in conjunction with the accompanying drawings.

[0018] As shown in the figure, the bagging mechanism of the bagging machine of the present invention is composed of a suction bag part 5, a bag opening part 1, a bag clamping part 2 and a material pushing part 3. Comprising a bag opening arm 10 and a bag opening cam 15, the bag opening arm 10 is fixed on the bag opening arm seat 12, the bag opening arm seat 12 takes the bag opening rotating shaft 11 as a fulcrum for horizontal swing setting, and the bag opening arm seat 12 is installed with a Bag roller 14 and bag-opening return spring 13, the tension of bag-opening return spring 13 makes bag-opening roller 14 lean against the cam surface of bag-opening cam 15; Bag arm 20 and bag clamping cam 24, bag clamping arm 20 is positioned at the outside of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com