Automatic unpacking and discharging device

An unloading device, automatic technology, applied in packaging, transportation and packaging, cutting and unsealing, etc., can solve the problems of complex adaptability and large size of the mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

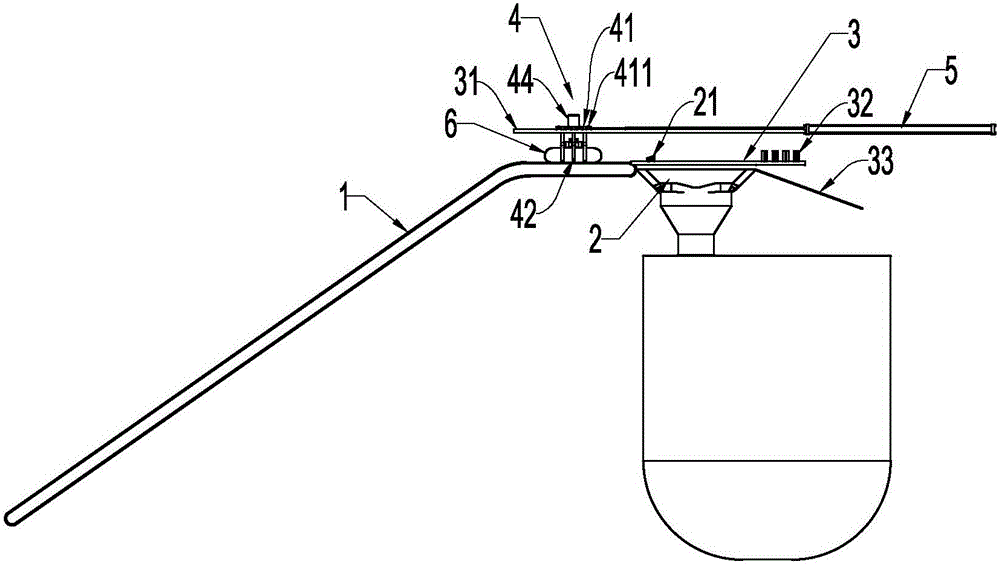

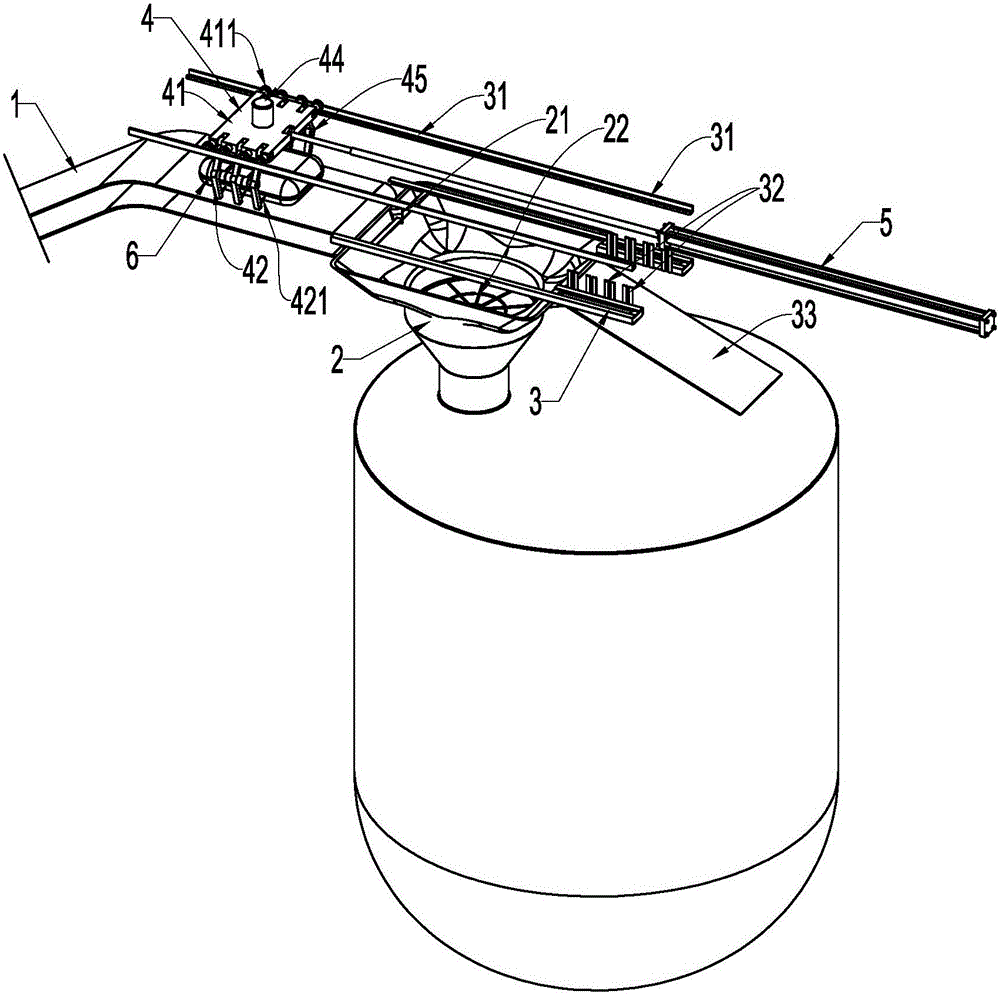

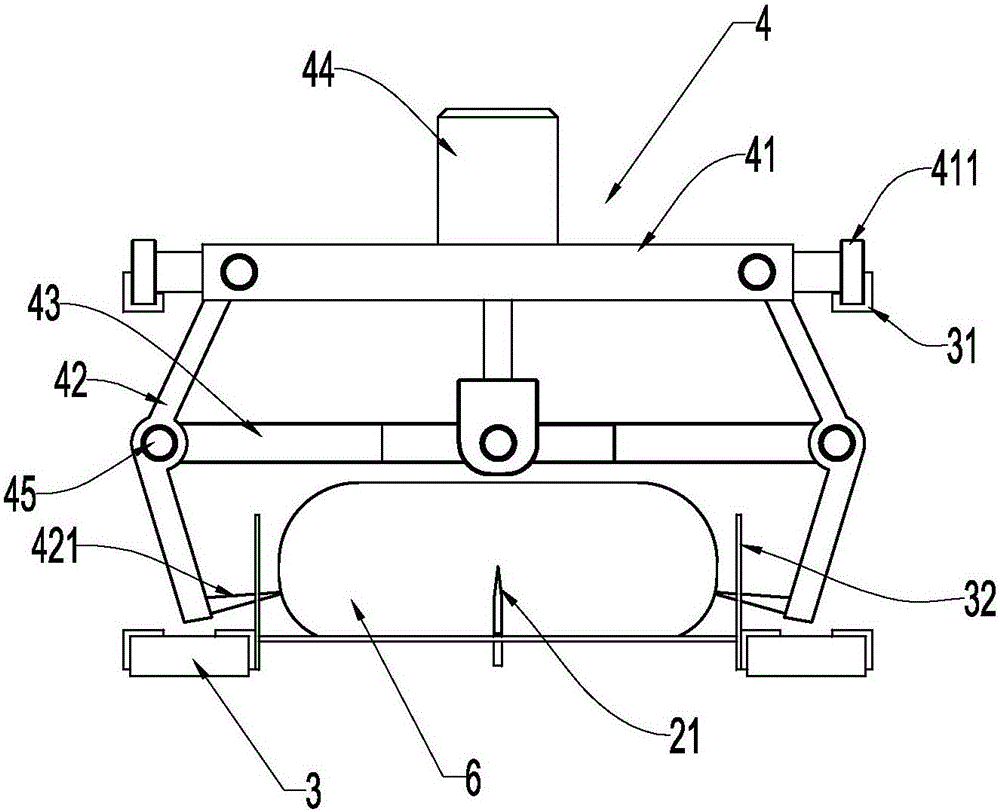

[0021] refer to figure 1 , figure 2 and image 3 , an automatic unpacking and unloading device, including a conveyor belt 1, a hopper 2, a frame 3, a manipulator 4 walking on the frame, and a driving mechanism 5, and a storage tank or other material equipment is attached below the hopper 2; the conveyor belt 1 extends to the edge of the hopper 2, the frame 3 is erected above the hopper 2, a pair of guide rails 31 are arranged in parallel on the frame 3, and the manipulator 4 is placed on the guide rails 31; A plurality of claws 42, connecting rods 43 and hydraulic cylinders 44 on both sides; the claws 42 on both sides are arranged opposite to each other, and the middle part of the claws on the same side is strung together through an intermediate shaft 45, which is pulled by a connecting rod 43, The other ends of the two connecting rods 43 are hinged on the same axis at the piston end of the hydraulic cylinder 44 at the same time, and the claws 42 on both sides are driven by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com