Braking device integrated with safety gear and lifting mechanism

A brake device and lifting mechanism technology, which is applied in the field of brake devices and safety brake devices for elevators, can solve the problems of long installation time, high labor intensity of workers, and cumbersome installation process, so as to reduce site safety risks and improve Installation efficiency and assembly accuracy, time-saving effect of installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

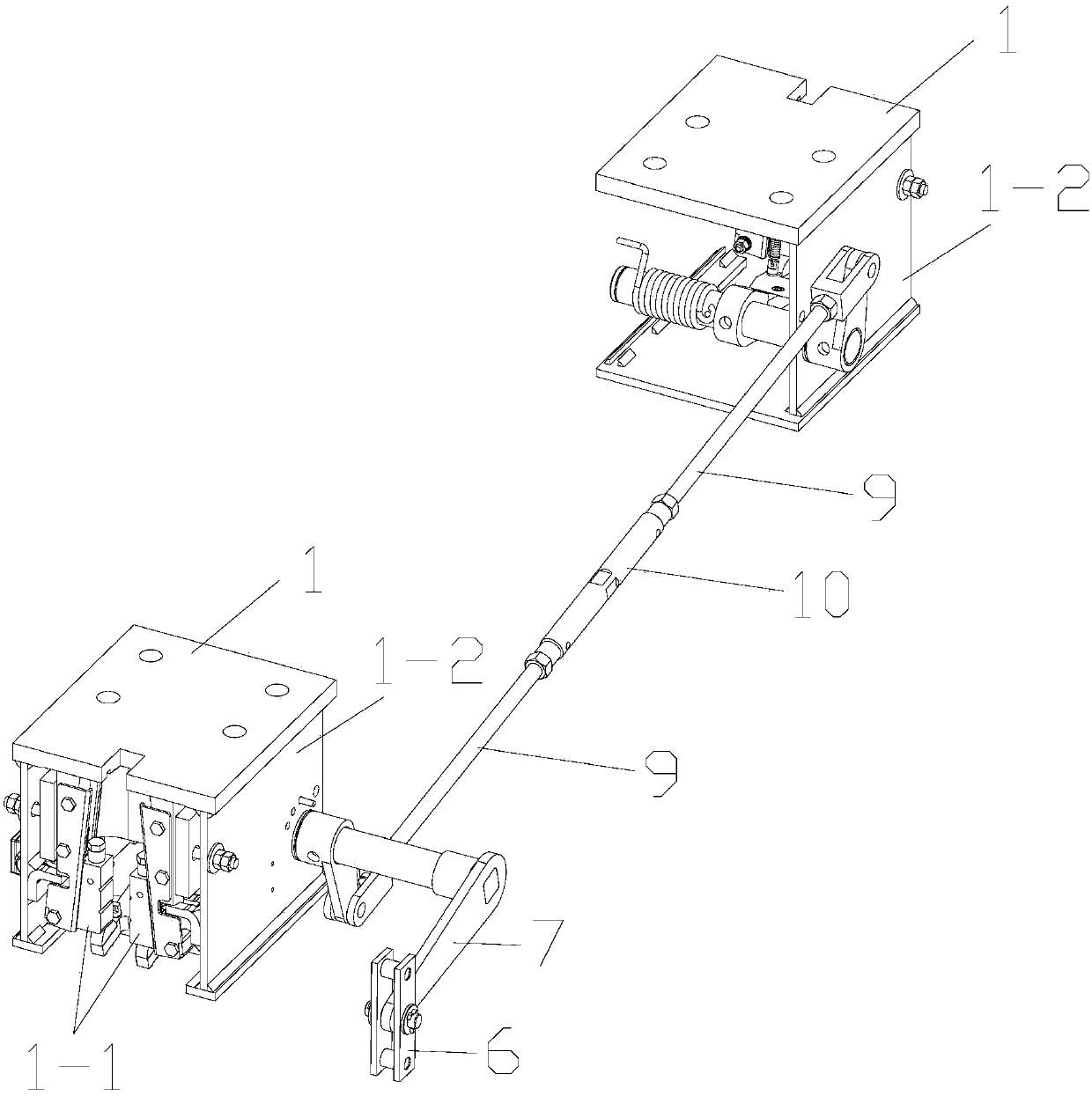

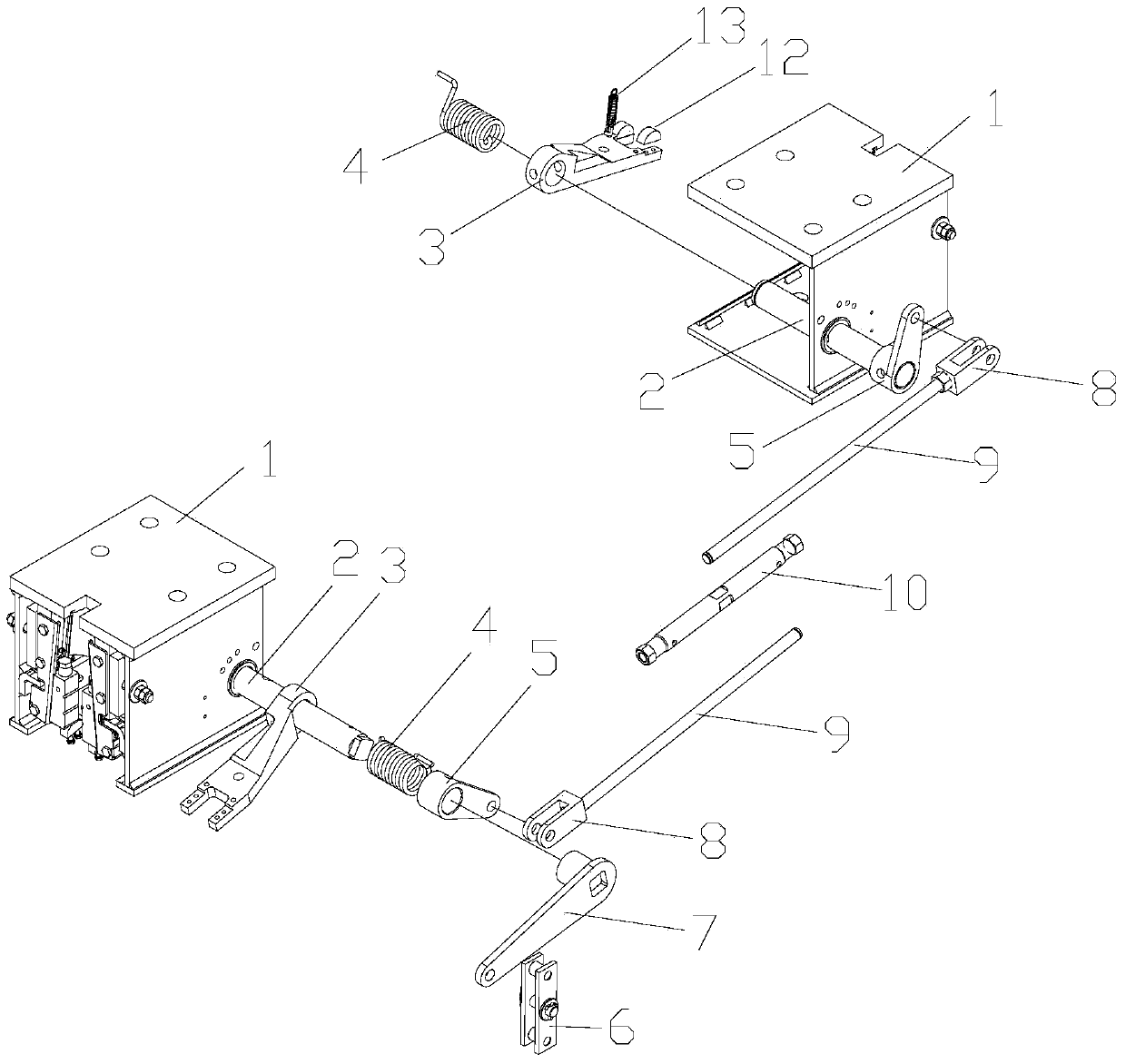

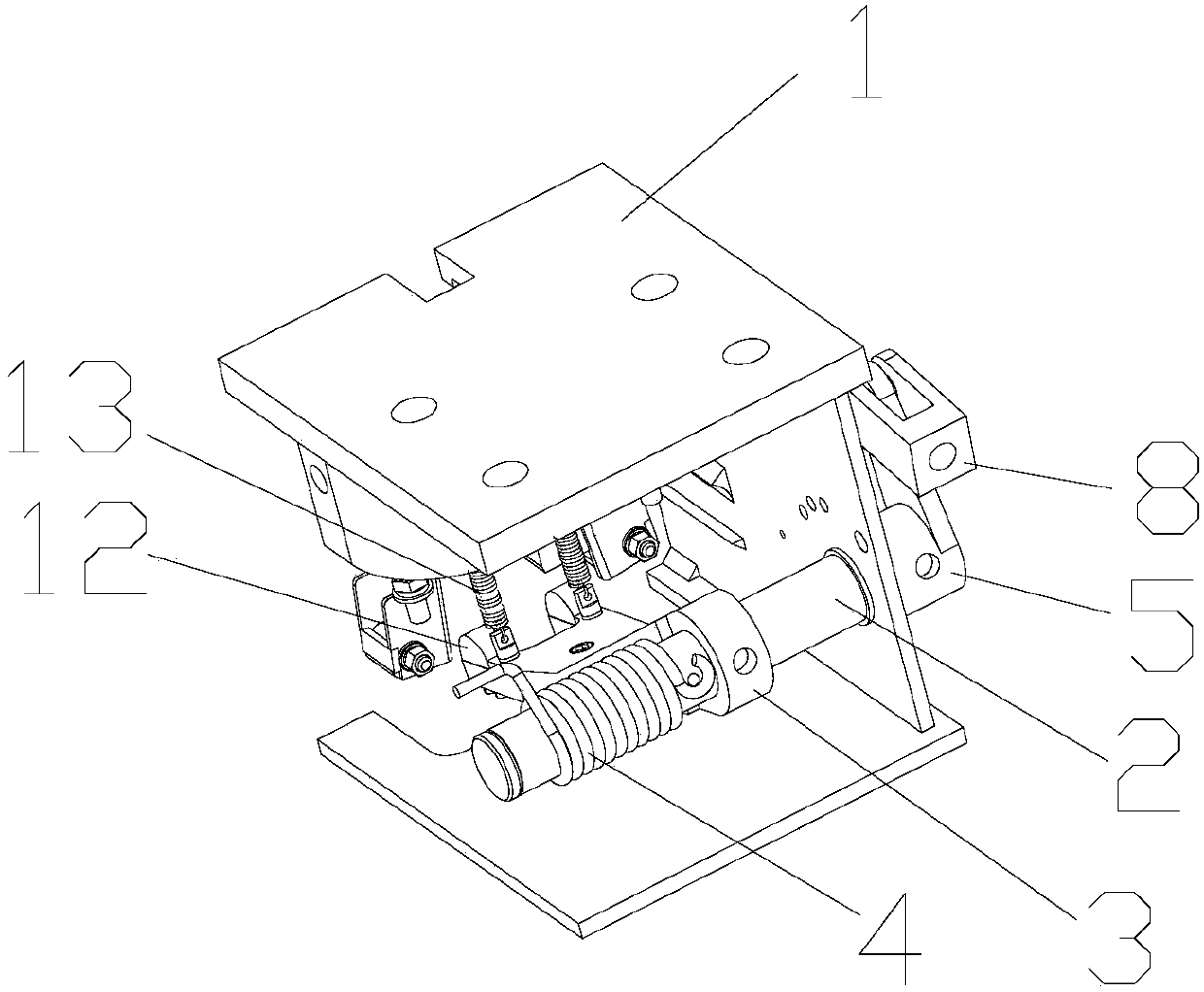

[0032] The preferred embodiments of the invention will be described in detail below in conjunction with the accompanying drawings.

[0033] see Figure 1-3 , this embodiment includes two safety gears 1, rotating shaft 2, shift fork 3, torsion spring 4, short pull plate 5, pull head 6, long pull plate 7, pull connection end 8, left and right threaded rods 9, Closed rigging turnbuckle 10, cam 12, extension spring 13, etc. The safety gear 1 shown in this embodiment is a symmetrical progressive safety gear, and its inner rear part has an installation space for a lifting mechanism; if the safety gear body is not lifted The installation space of the pulling mechanism can also be increased through the safety gear body to obtain a space for installing the pulling mechanism.

[0034] Each safety gear 1 is provided with two movable wedges 1-1 and side plates 1-2.

[0035] The rotating shaft 2 transversely passes through and rotates the side plate 1-2 matching the safety gear, its inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com