Novel motor stator and winding installing technology thereof

A motor and stator technology, which is applied in the field of new motor stator and winding installation technology, can solve the problems of low productivity, waste of manpower, labor cost, etc., achieve the effects of improving production efficiency and quality, saving a lot of costs, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

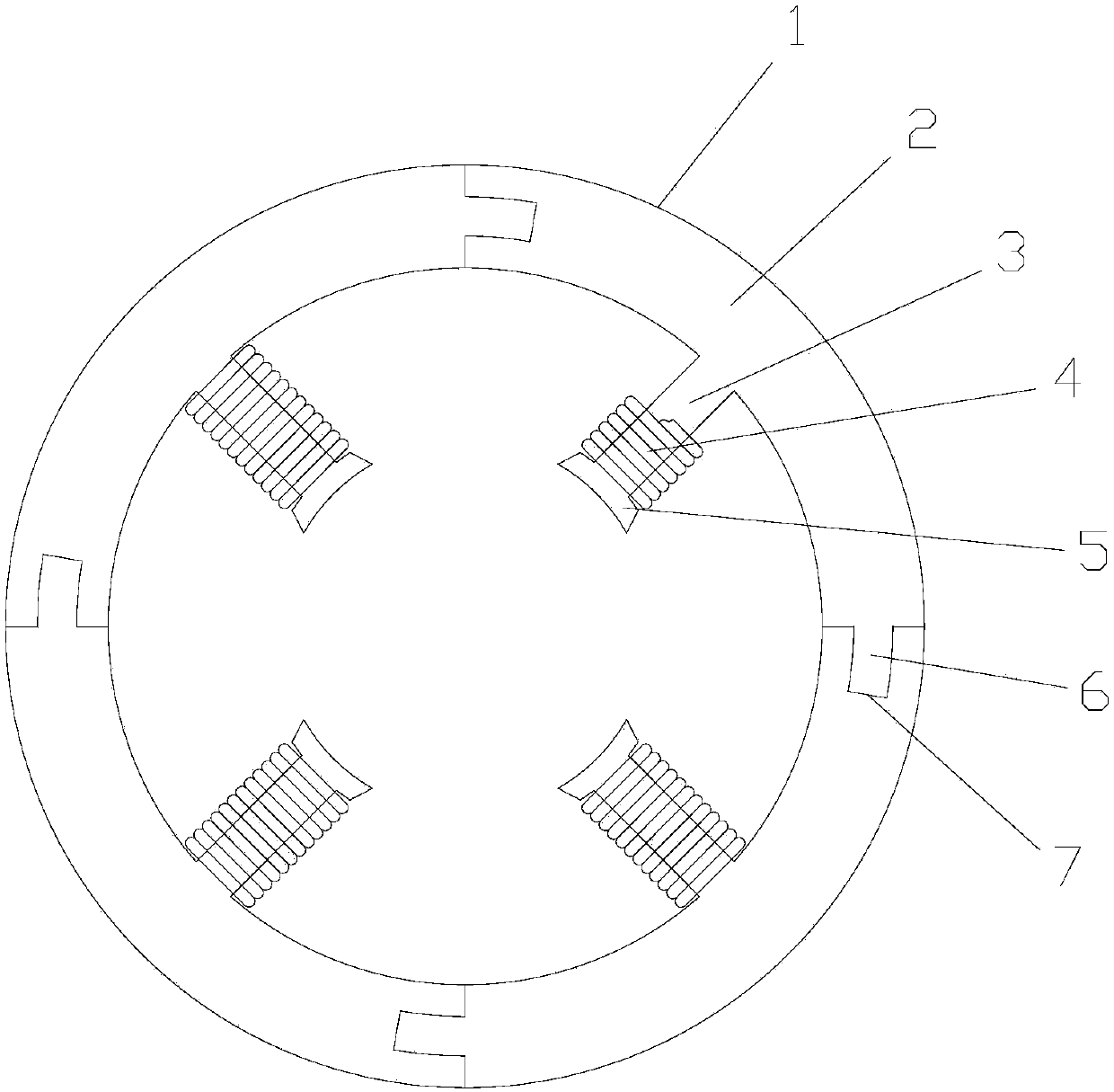

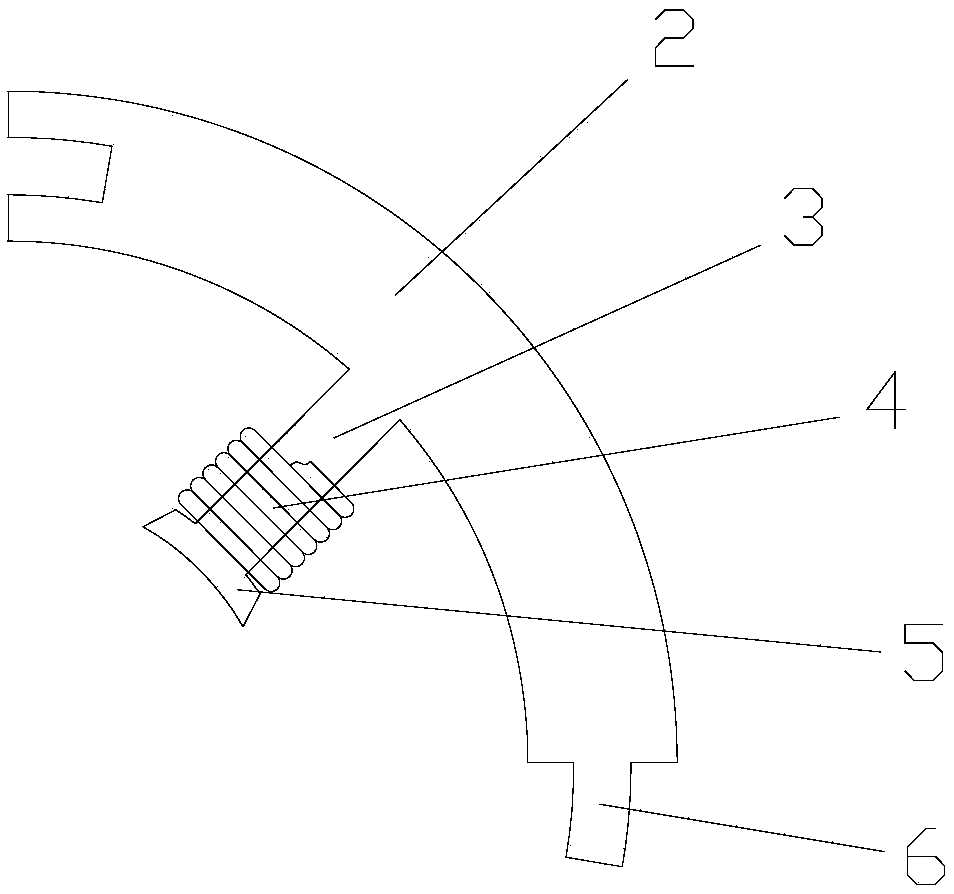

[0021] Such as figure 1 , 2 As shown, taking a four-stage motor as an example, the new motor stator of this embodiment includes a stator core 1 and a coil 4 wound on the stator core 1, and the stator core 1 includes a plurality of core blocks 2; The iron core blocks 2 are arc-shaped and each iron core block 2 is connected end to end along the circumferential direction to form a circular stator core 1. The structure of each iron core block 2 is the same, which is convenient for batch manufacturing and mechanized production. The structure of the stator core 1 can respectively wind the coil 4 on each core block 2 constituting the stator core 1, which solves the technical problem of limited operating space for winding the coil 4 in the prior art, and the production efficiency and quality are compared Compared with the existing technology, it can save a lot of cost; the core blocks 2 are connected through the flange 6 and the groove 7, and the corresponding configuration of the fl...

Embodiment 2

[0024] The novel motor winding installation process of the present invention specifically comprises the following steps:

[0025] a. First stack each silicon steel sheet of each iron core block 2, press them tightly with a machine, and each part forms a separate iron core block 2;

[0026] b. Wind the coil 4 to the magnetic pole 3 of the iron core block 2 with a winding machine, throw out the two wire ends separately, and wait to be connected with the wire ends of the coil 4 on other magnetic poles 3 to form a stator winding;

[0027] c. Press the iron core blocks 2 with the stator windings together from top to bottom according to the order, so that the adjacent iron core blocks 2 are connected into a closed circle through the flange 6 and the groove 7, forming stator;

[0028] d. Put the installed stator into the motor casing, then put it into the motor rotor, and put on the end cover to form a complete motor.

[0029] Compared with the existing technology, the production e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com