Kitchen waste filter liquid oil removal tank and oil removal system thereof

A technology for food waste and oil tanks, which is applied in the field of food waste filtrate degreasing tanks and its degreasing system, which can solve the problem of inability to directly observe the position of the grease layer 15 in the tank, the single style of the water distribution system, and the unfavorable rise of oil slicks and other problems, to achieve the effect of easy industrial production operation, high moisture content in oil discharge, and convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

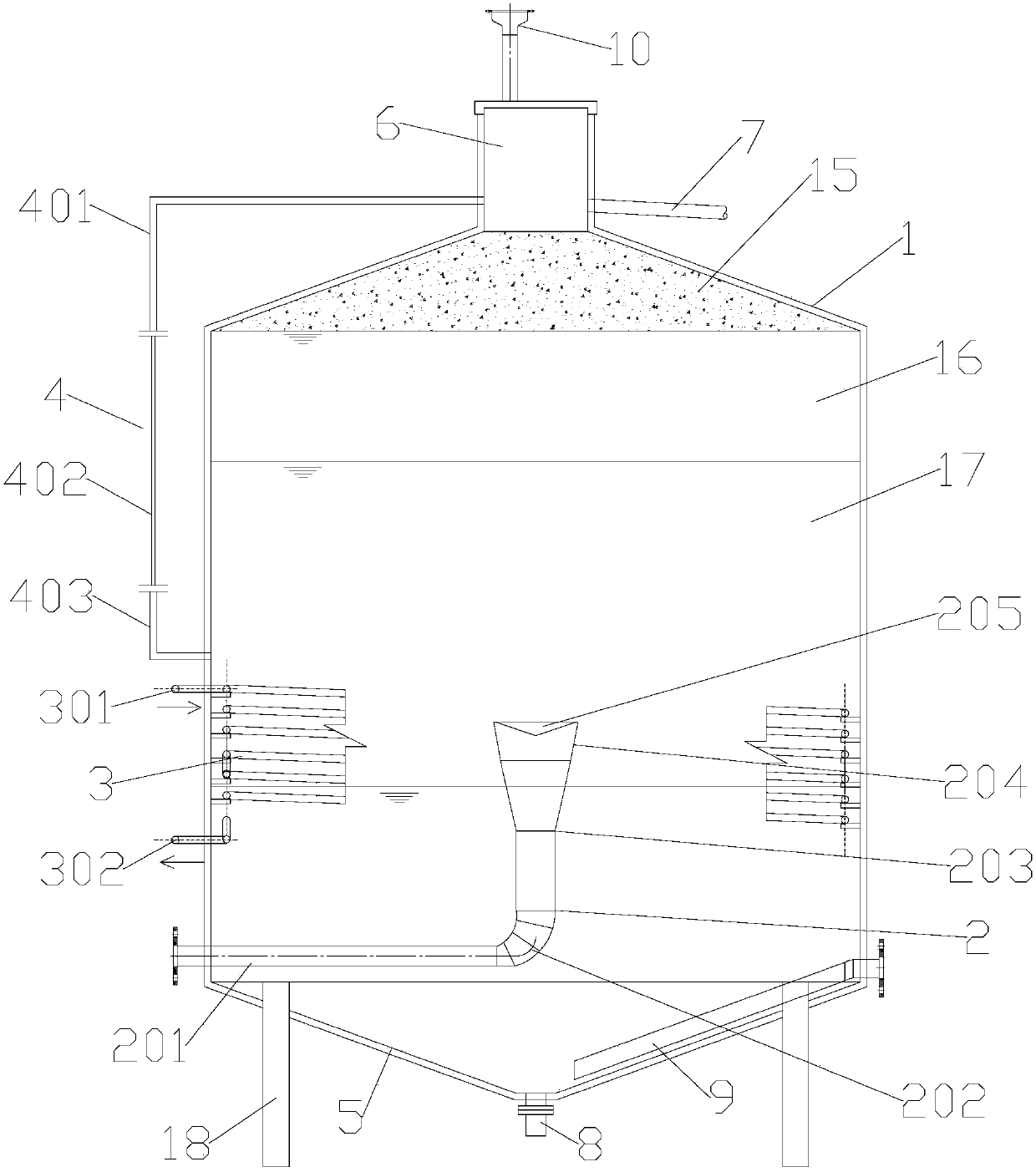

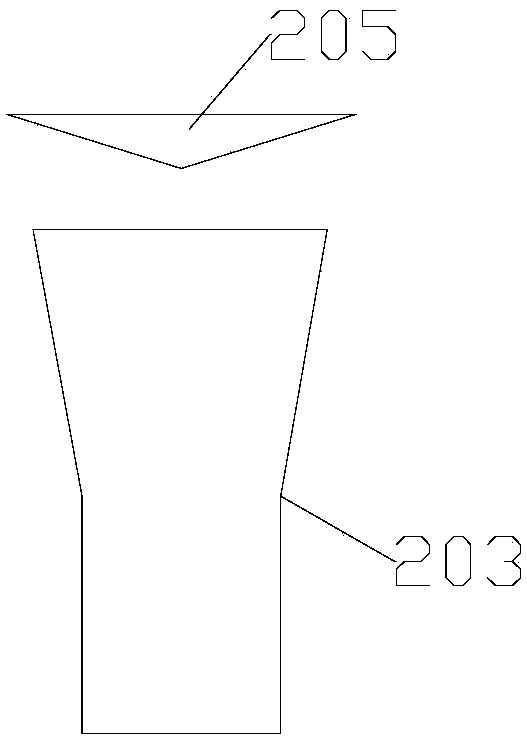

[0052] like figure 1 and figure 2 As shown, a kitchen waste filtrate degreasing tank includes a tank body 1;

[0053] The tank body 1 is provided with a water distribution device 2 and a heating device 3; an oil level observation device 4 is provided outside the tank body 1; The upper end of the water distribution device 2 extends to the position of the heating device 3, and its top height is less than the top height of the heating device 3; the heating device 3 is located in the lower middle of the tank body 1; bit observation device 4;

[0054] The oil level observation device 4 includes a plexiglass tube 402; the upper end and the lower end of the plexiglass tube 402 are respectively connected with a first stainless steel communication tube 401 and a second stainless steel communication tube 403 through flanges; the first stainless steel communication tube 401 Connected to the oil outlet 6 at the top of the tank body 1 , the second stainless steel communication pipe 403...

Embodiment 2

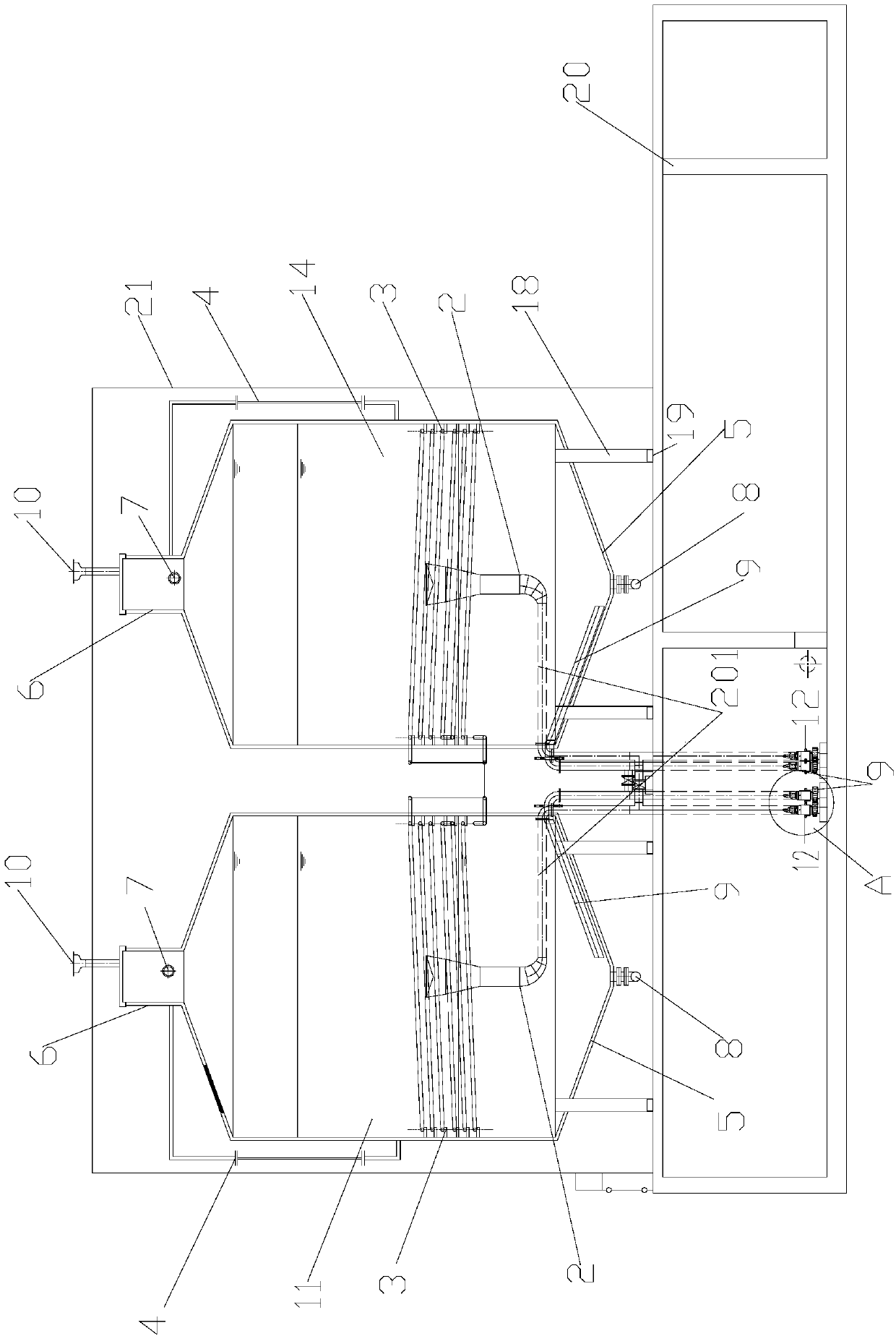

[0084] The kitchen waste filtrate degreasing tank and its degreasing system described in this embodiment are basically the same as those in Embodiment 1, except that: Figure 7-9 As shown, the elbow 2 of the water distribution device is an equal diameter elbow, preferably a 90° elbow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com