Glass cutting device

A glass cutting and cutting knife technology, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of high cutting temperature, short service life, excess glass debris, etc., to ensure smoothness and prolong service life , the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing of description, the present invention will be further described.

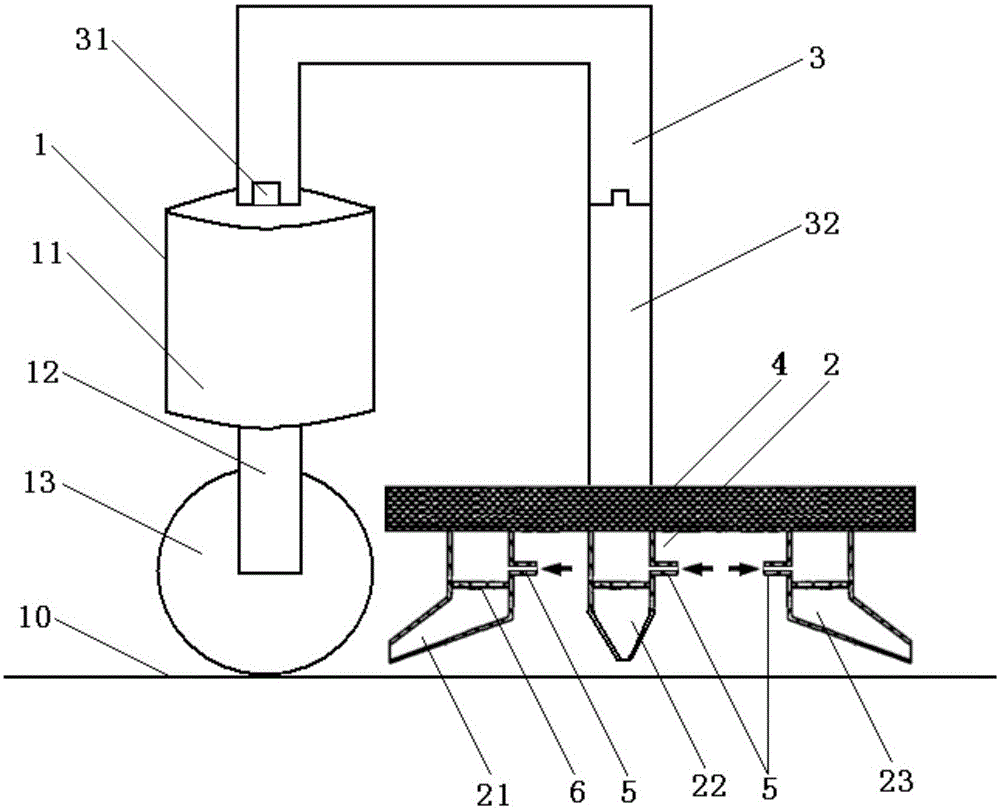

[0021] Such as figure 1 The shown glass cutting device includes a cutter body 1, a cooling device 2 arranged side by side with the cutter body 1, and an inverted U-shaped bracket 3 connecting the cutter body 1 and the cooling device 2; the cutter body 1 , the support 3 and the cooling device 2 are sequentially distributed along the cutting movement direction.

[0022] The cutter body 1 includes a cutting frame 11 connected to one end of the support 3, and is connected to the cutter wheel 13 at the bottom of the cutting frame 11 through a wheel pin 12; the cooling device 2 includes a support plate 4 connected to the other end of the support 3, The first air nozzle 21 is arranged on the bottom surface of the support plate 4 and faces the cutter wheel 13 ; the first air nozzle 21 is supplied with cooling gas through the air pipe 5 . An air screen 6 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com