Handmade soap model gradual change technology

A handmade soap and molding technology, which is applied in the direction of molding soap, detergent materials, chemical instruments and methods, etc., can solve the problems of soap block design damage, affecting user experience, incompleteness, etc., to reduce consumption, improve use effect, The effect of enhancing user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

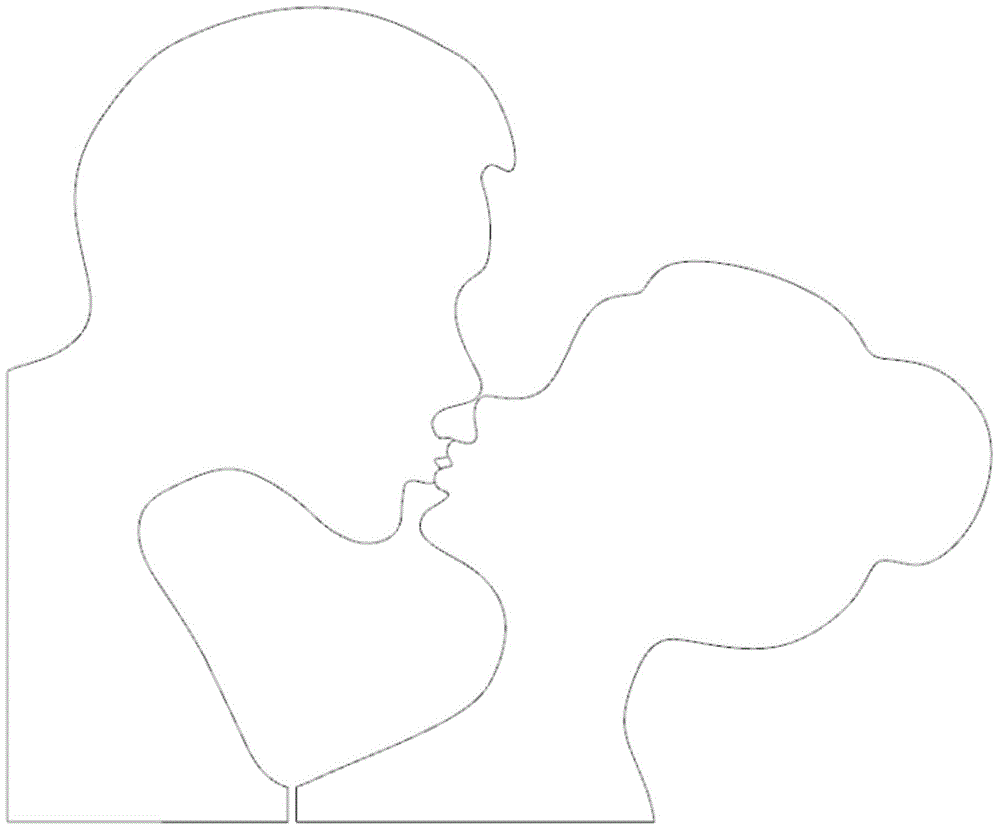

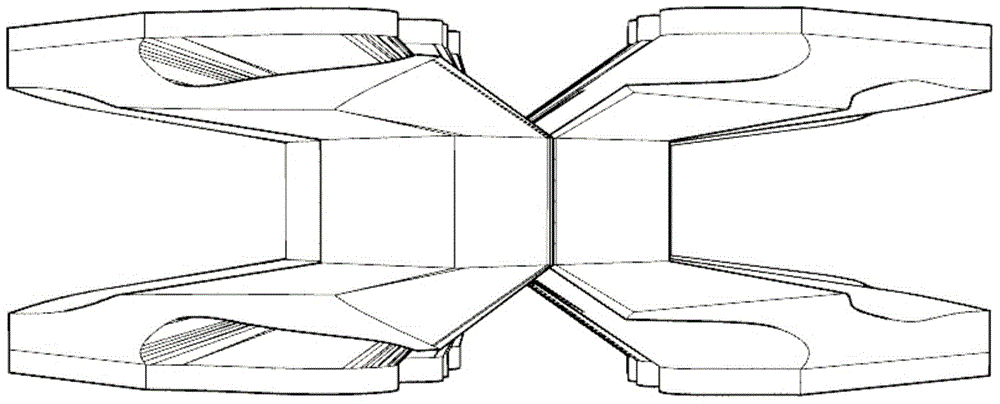

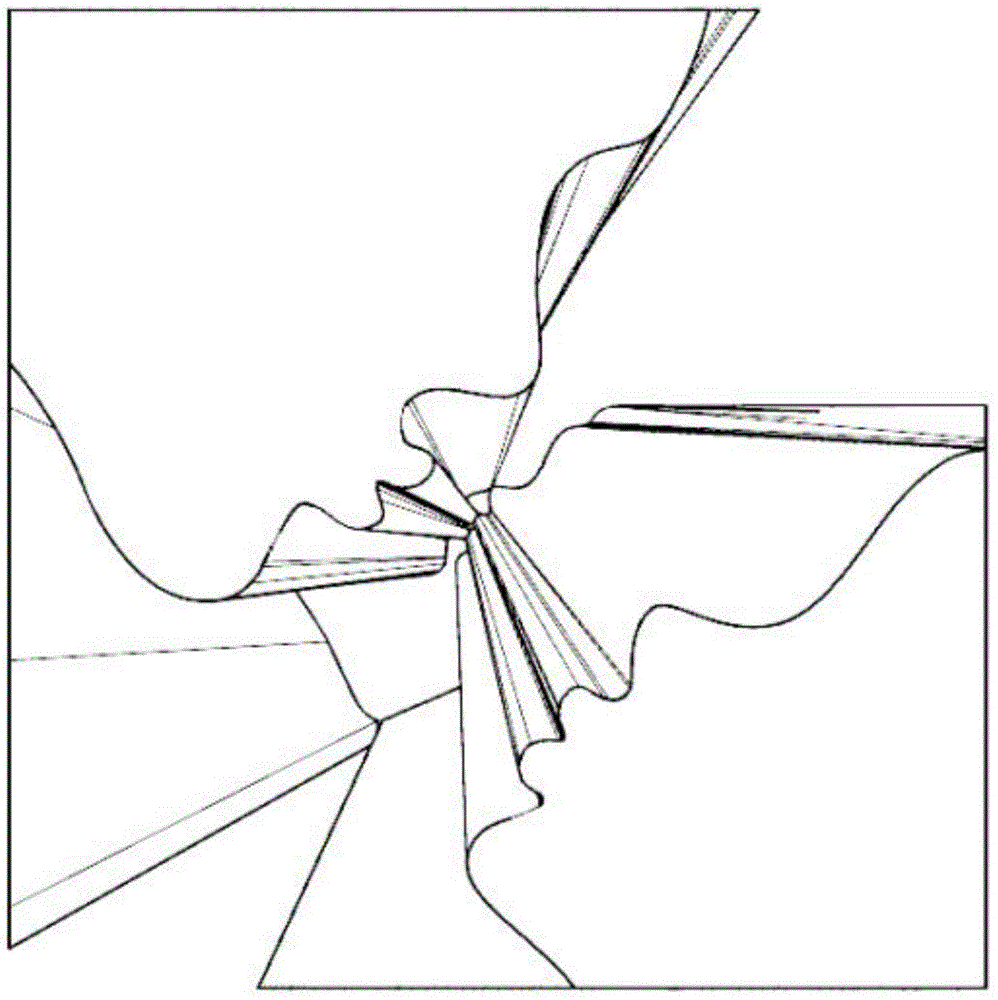

[0018] The handmade soap modeling gradient process in the embodiment of the present invention adopts a brand-new design principle of animation and projection, makes molds through 3D software and 3D printing equipment, uses fine expressive techniques, and uses handmade soap modeling to become smaller with the loss of soap blocks and can be gradually butted, so that the soap can be used from new to final use to achieve a relatively complete pattern. The handmade soap itself shrinks as it is used, so that the shape of the worn surface gradually reaches the center of the soap body and then docks to show another shape combination. Specifically, taking the lover-themed soap as an example, the manufacturing process steps are as follows:

[0019] 1) Make the first draft: Use 3D production software to formulate the final graphic scheme to be expressed and displayed. See the graphic scheme figure 1 , with the graphic scheme as the core, the animation and projection principles are used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com