Perpendicular electroplating device

A vertical electroplating and equipment technology, applied in the electrolysis process, electrolysis components, etc., can solve the problems affecting the electroplating effect of the workpiece to be electroplated, affecting the product quality, and the vibration of the electroplating hanger structure, so as to improve the electroplating effect, avoid vibration, and enhance reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

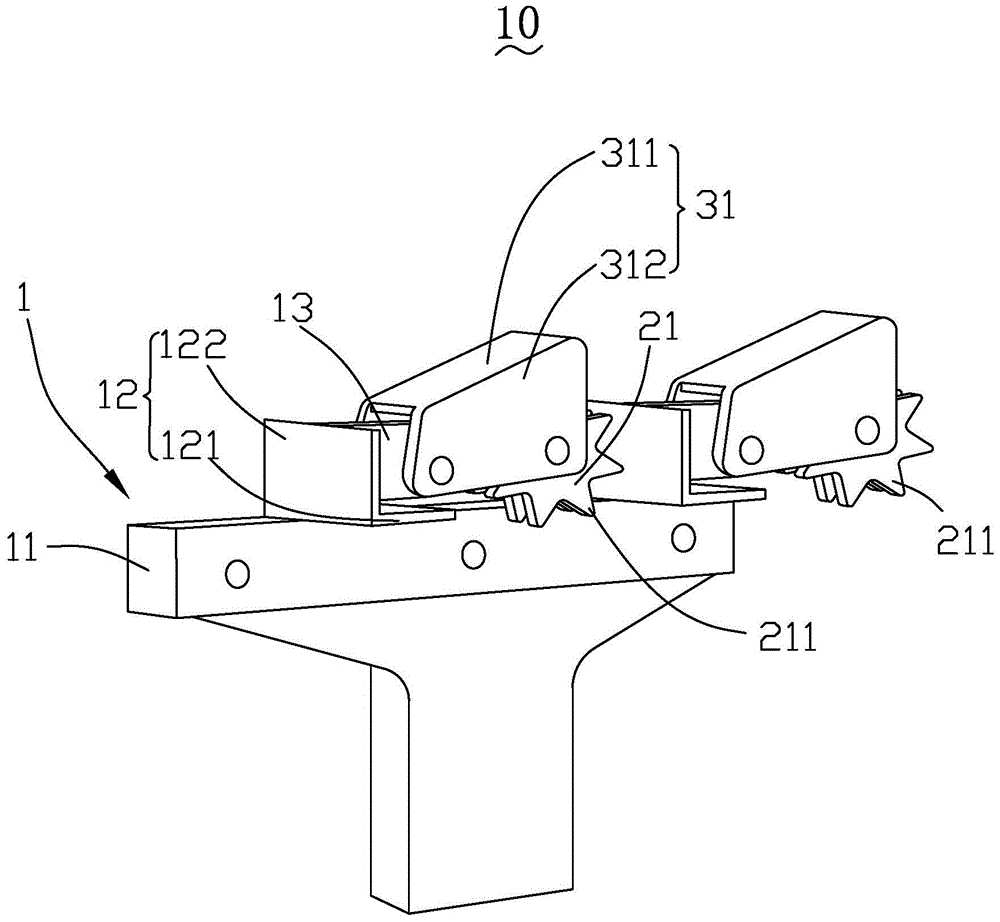

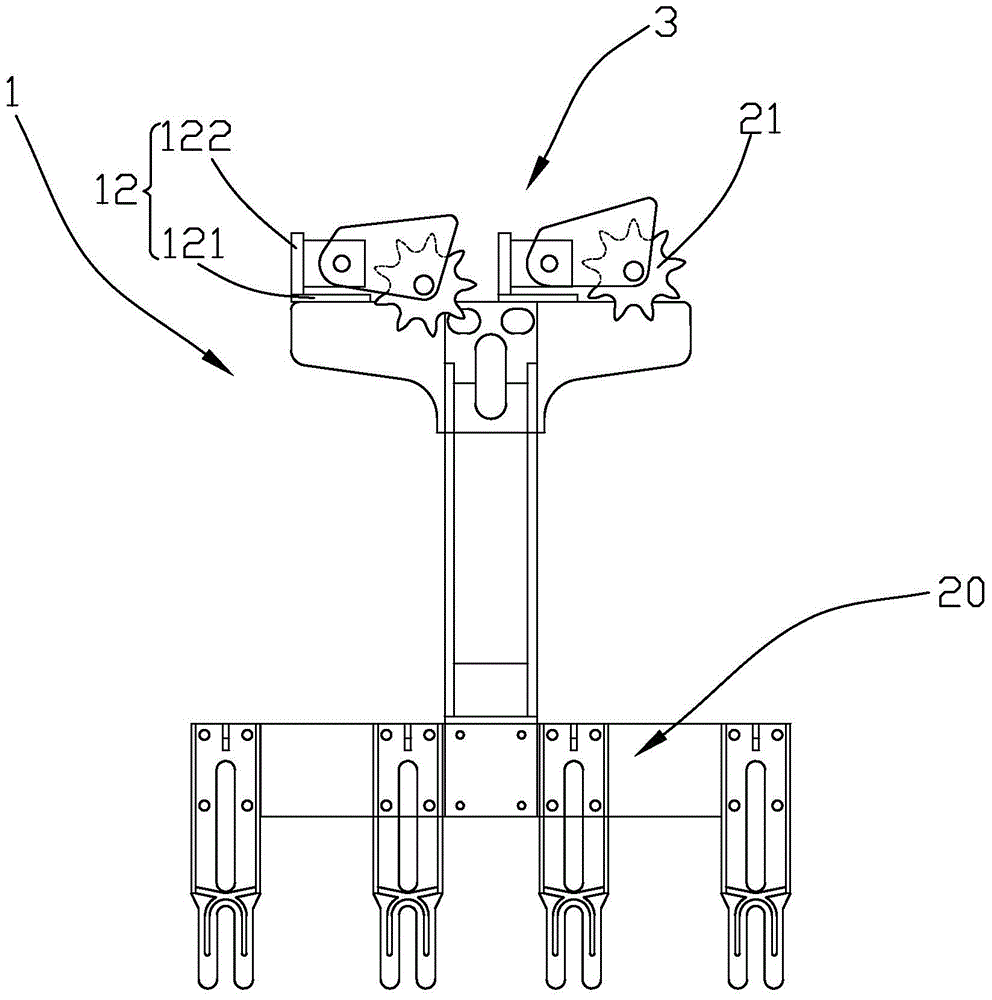

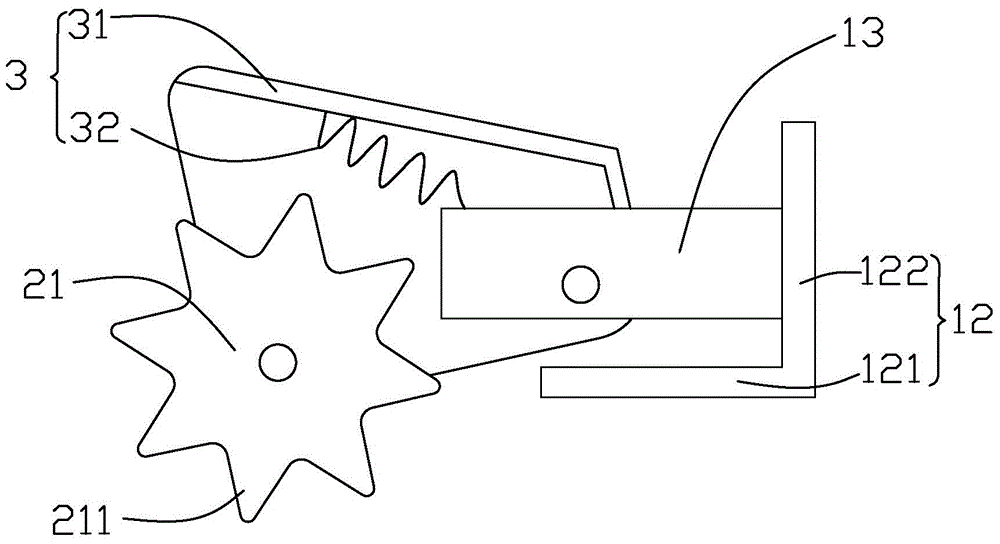

[0022] Please also see Figure 1 to Figure 3 , figure 1 It is a schematic diagram of the three-dimensional structure of the electroplating rack device of the vertical electroplating equipment of the present invention. figure 2 It is a structural schematic diagram of the assembly of the electroplating hanger device and the fixture of the vertical electroplating equipment of the present invention. image 3 It is a structural schematic diagram of a working state of the electroplating rack device of the vertical electroplating equipment of the present invention. The vertical electroplating equipment (not shown) includes a conveyor chain (not shown) and an electroplating rack device 10 hung on the conveyor chain. The electroplating hanger device 10 includes a fixed arm 1, a delivery device (not labeled) and an adaptive adjustment device 3, the delivery d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com