Adhesive tape type fabric sucker for industrial sewing machine

A technology for industrial sewing machines and tapes, which is applied in the direction of sewing machine components, sewing equipment, and cloth feeding mechanisms, etc., and can solve the problems that the cloth cannot be delivered to the required processing position, the troubles of automatic processing of industrial sewing machines, and the relative displacement between the cloth and the suction cup, etc. , to achieve the effect of convenient implementation, ingenious design and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

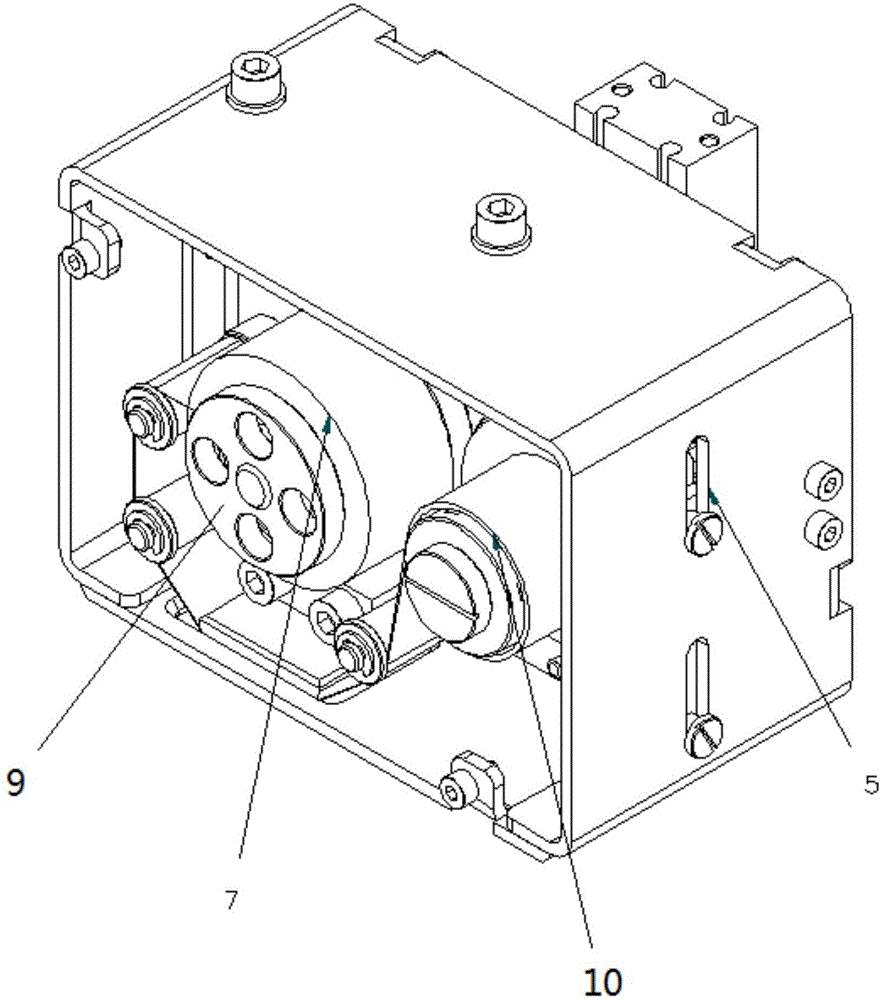

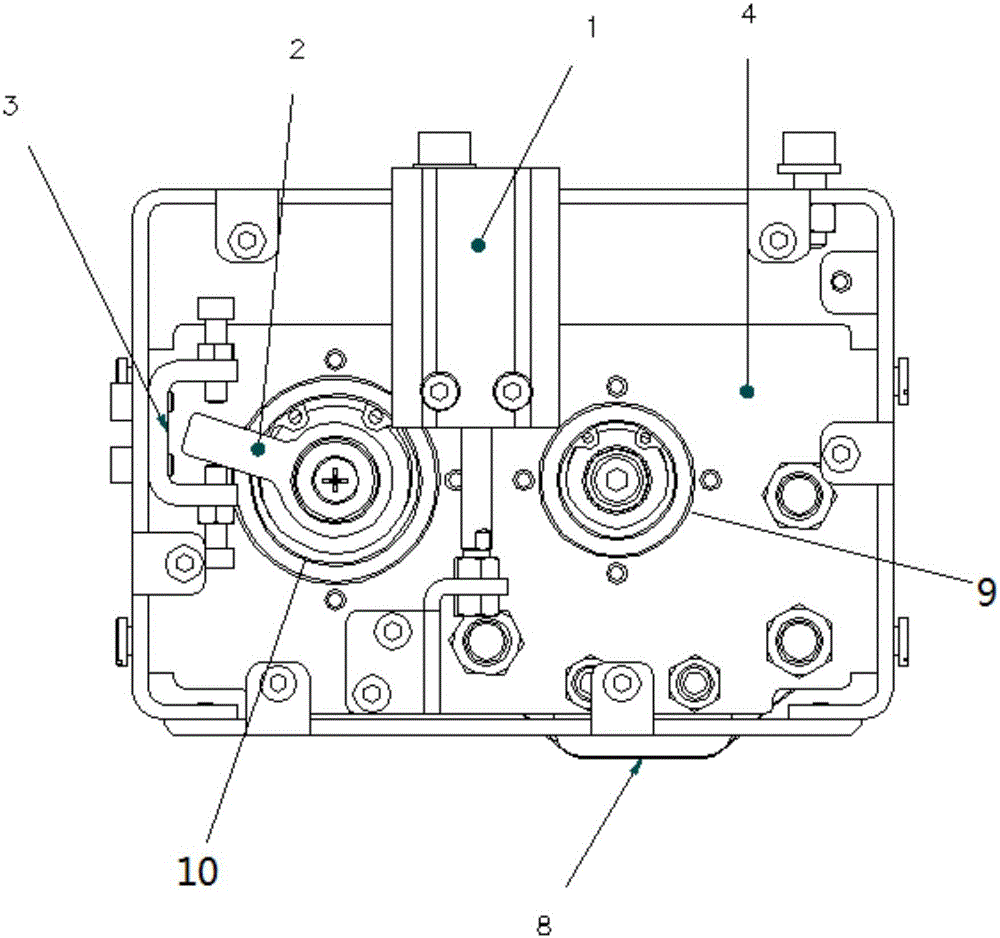

[0021] see Figure 1-Figure 2 , an industrial sewing machine tape-type cloth sucker, said comprising a housing, a cylinder 1 is vertically installed in said housing, said cylinder 1 telescopic ejector rod is fixedly connected with a tape rotating mechanism 4, and said tape rotating mechanism 4 is mounted on the cylinder 1 Driven to move up and down along the guide grooves 5 on both sides of the housing; the one-way wheel 10 and the driven wheel 9 are fixed on the tape rotation mechanism 4, the one-way wheel has a rocker arm 2, and the housing is equipped with a limiting member 3, the The rocker arm 2 is located in the upper and lower intervals of the limiting member 3; the adhesive tape 7 is wound on the one-way wheel 10 and the driven wheel 9, and the inner side of the adhesive tape is slidably attached to the suction cup 8, and the suction cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com