Application of bimetallic alloy in anti-carbon-deposition methane steam reforming catalyst

A reforming catalyst, carbon deposition methane technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, non-metallic elements, etc., can solve the problem of high price, NiAg and NiCu alloy cannot exist stably And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

[0019] A bimetallic alloy for an anti-coking methane steam reforming catalyst, the bimetallic alloy is composed of two metals, and the general formula is A x B y , wherein, A is one of Fe, Co, Ni, and B is one of Ga, Zn, Sn.

[0020] In order to ensure that the activity of the alloy is higher than that of the noble metal Pt, alloy A x B y In x≥y, in order to ensure the anti-carbon performance of the material, usually x≤3y.

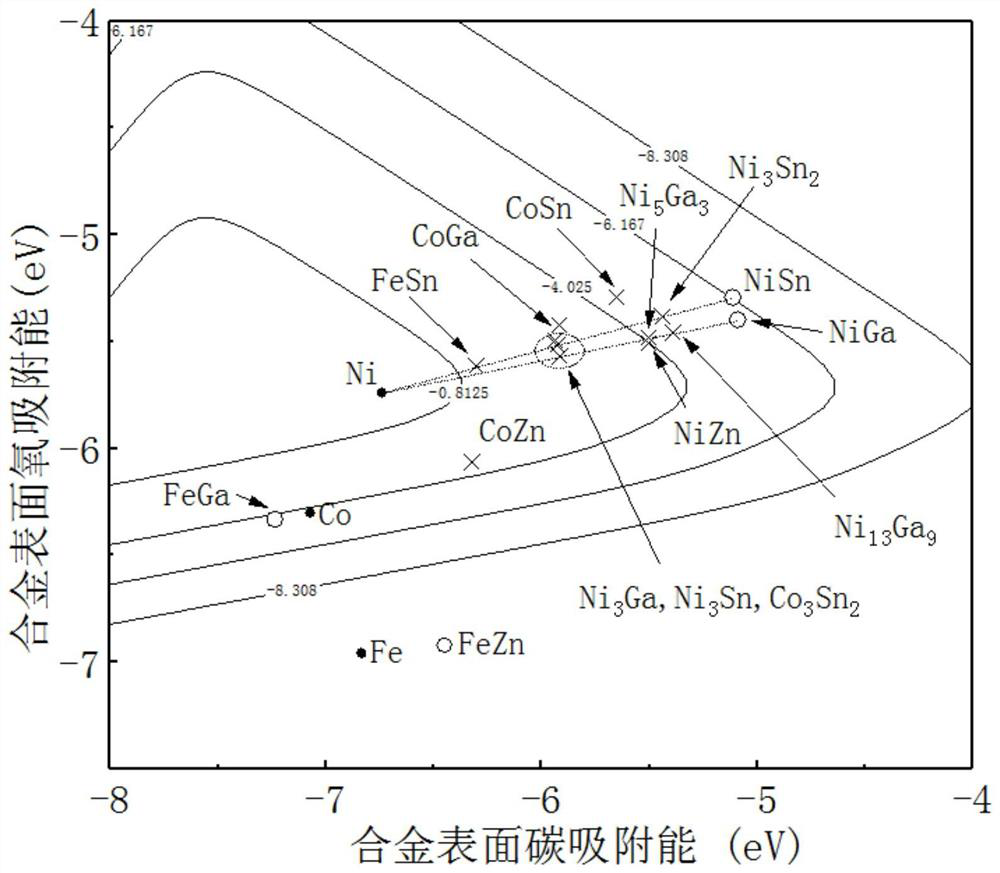

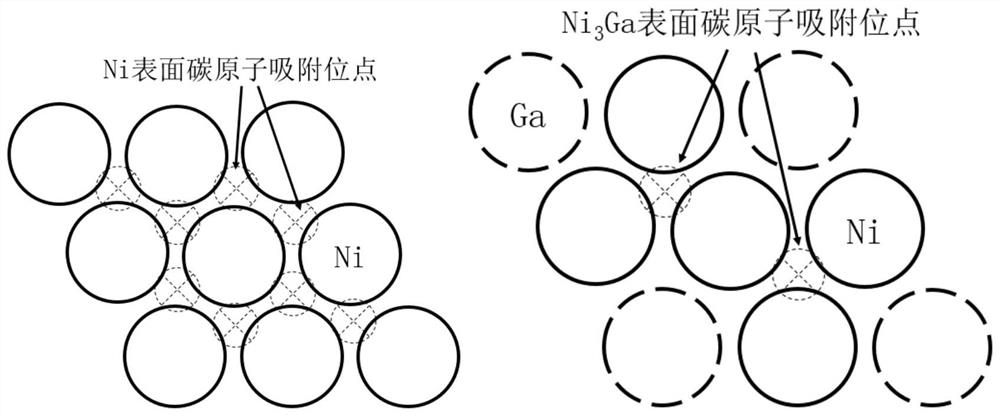

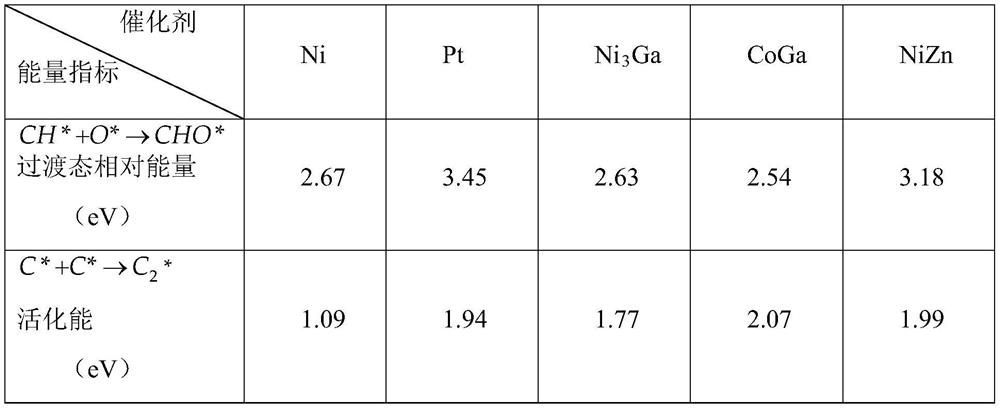

[0021] Such as figure 1 As shown, the methane water vapor reforming activity on the surface of the catalyst can be determined according to the adsorption energy of carbon and oxygen on the surface, where the curve marked with the value is the isoactivity line, the number on the line is the activity, and the value is expressed by Log 10 r is obtained, where r is the reaction rate, the unit is mol / cm 2 / s; Accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com