Dust-accumulation-proof fan propeller with reverse-droplet-shaped blades and disk-shaped back plate

An anti-drop-shaped, fan impeller technology, used in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as personnel and equipment safety accidents, strong vibration, etc., to achieve reliable use, high strength, and material saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Now in conjunction with accompanying drawing, the present invention is described in further detail.

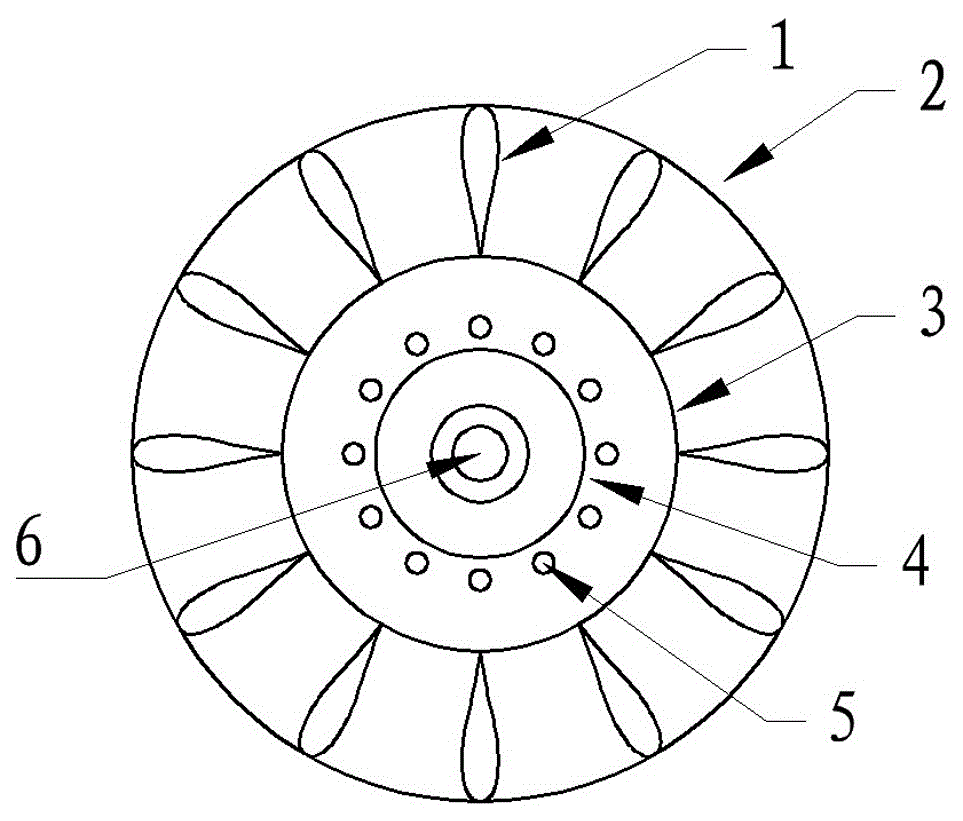

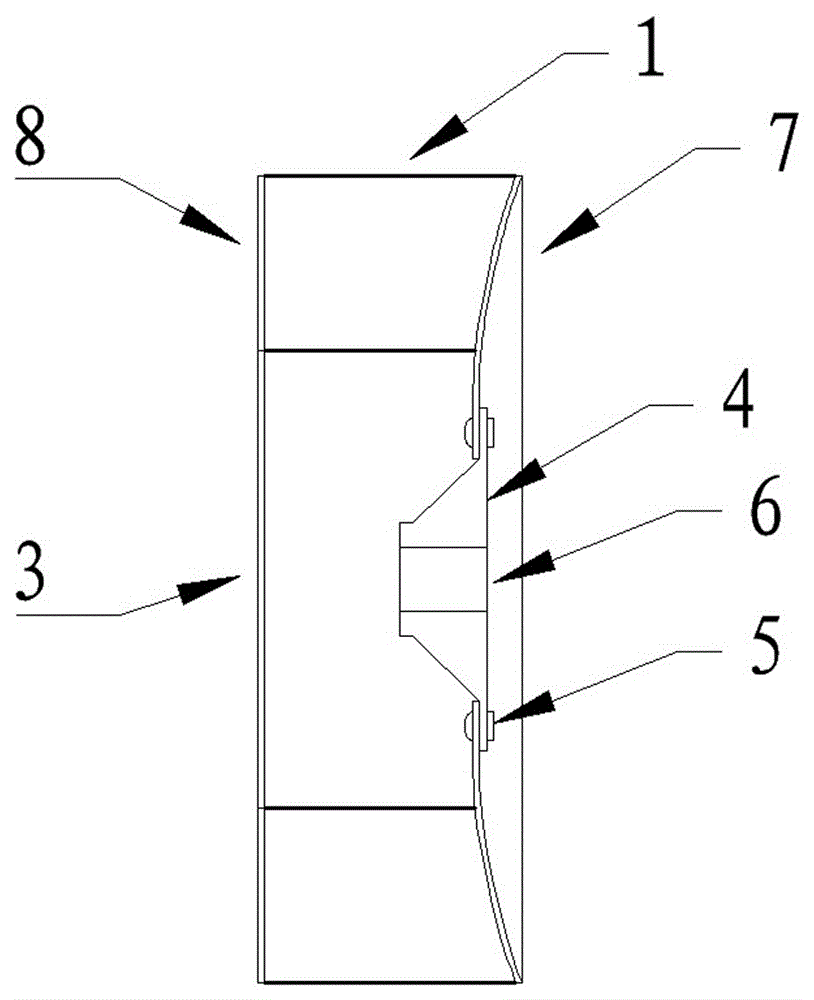

[0021] Such as figure 1 and figure 2 The impeller of the anti-dust fan with the blades shown as anti-droplets and dish-shaped backboards includes the impeller backboard 7, the impeller panel 8 and the blades 1. The blades 1 are arranged in a hollow anti-waterdrop shape radial to the impeller axis and symmetrical to the center. The impeller back plate 7 is dish-shaped; the hollow anti-drop-shaped blade 1 is connected to the impeller panel 8 and welded with the disc-shaped impeller back plate 7 to form the impeller main body; the impeller panel 8 is provided with an air inlet 3, and the disc-shaped impeller back plate 7 is fixed by rivets 5 And connect the shaft seat 4, the shaft seat 4 is matched with the fan shaft through the shaft hole 6.

[0022] The hollow anti-drop-shaped blade 1 is welded and combined by two curved metals, and has a symmetrical streamlined shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com