Transmission overdrive gear shaft system device

An overspeed gear and gear shaft technology, applied in transmission parts, gear lubrication/cooling, belts/chains/gears, etc., can solve the problems of limited noise reduction, shaft ablation, etc. The effect of improving bending strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

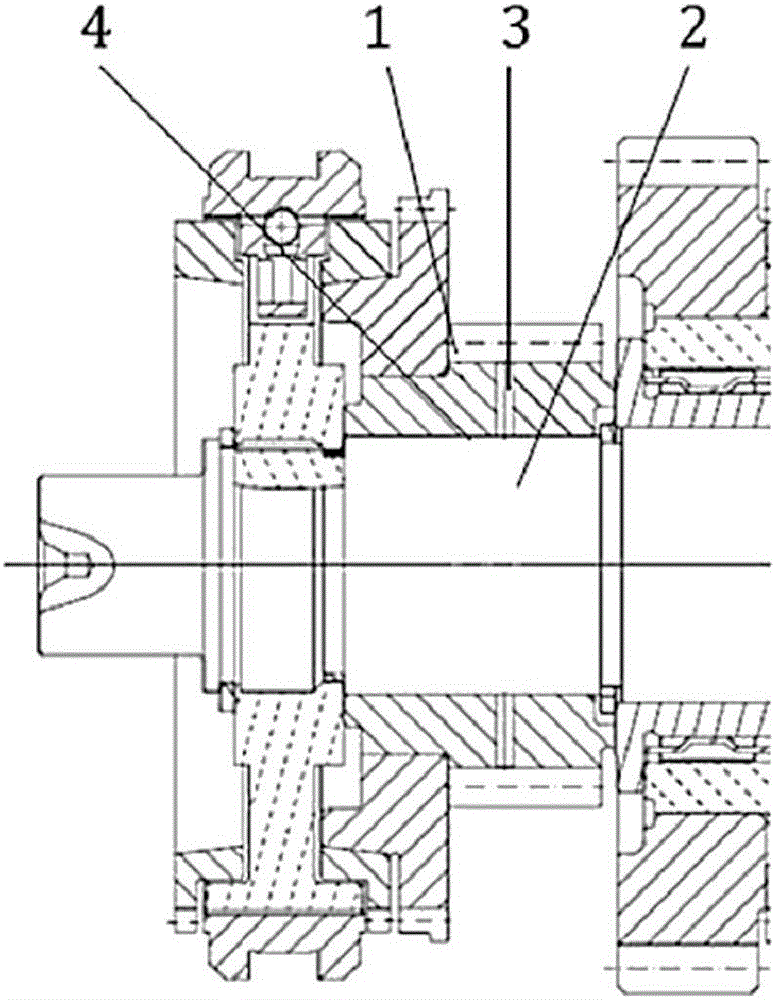

[0020] Such as figure 1 As shown, this embodiment includes: the overdrive gear passive gear 1 and the matching shaft 2, wherein: the overdrive gear passive gear 1 cooperates with the matching shaft 2 with a small gap, so that the driven gear can be suspended and rotated at high speed by the gear oil.

[0021] The gap of the small gap fit is 0.05-0.08 mm.

[0022] The matching shaft 2 is the part where the output shaft cooperates with the overdrive passive gear 1 .

[0023] A lubricating groove 4 is provided on the matching shaft 2 .

[0024] The inner surface of the overdrive passive gear 1 is provided with an oil hole 3 connected with a lubricating groove 4 .

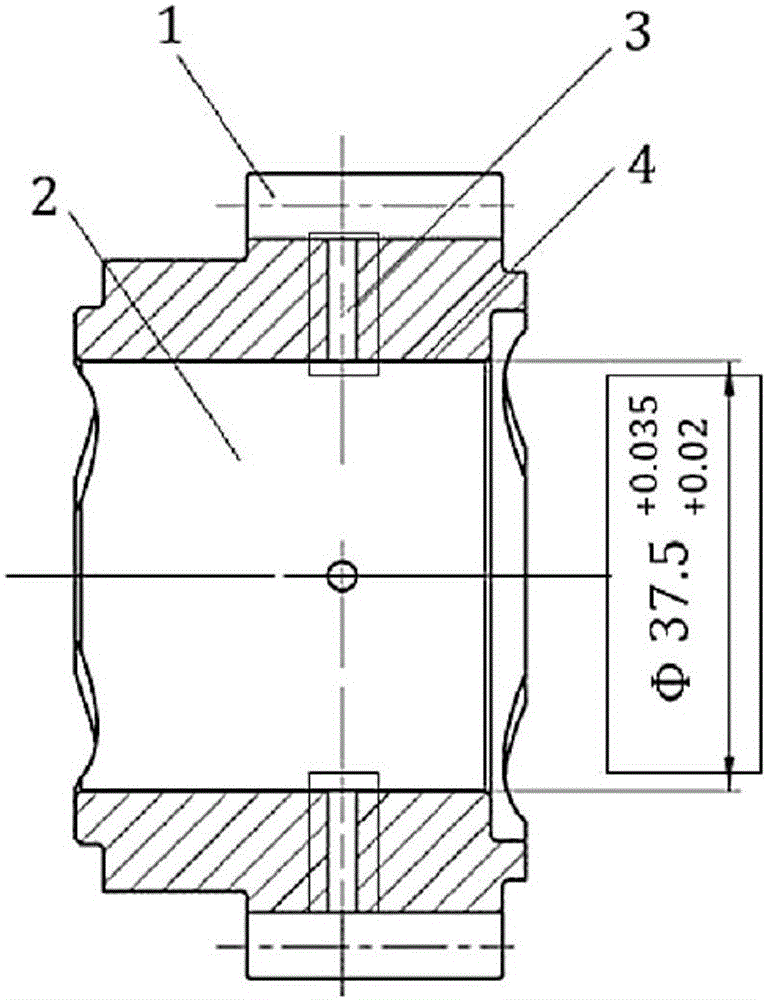

[0025] Such as figure 2 and image 3 As shown, the diameter of the matching shaft is 37.5mm, and the tolerance is 0.015mm.

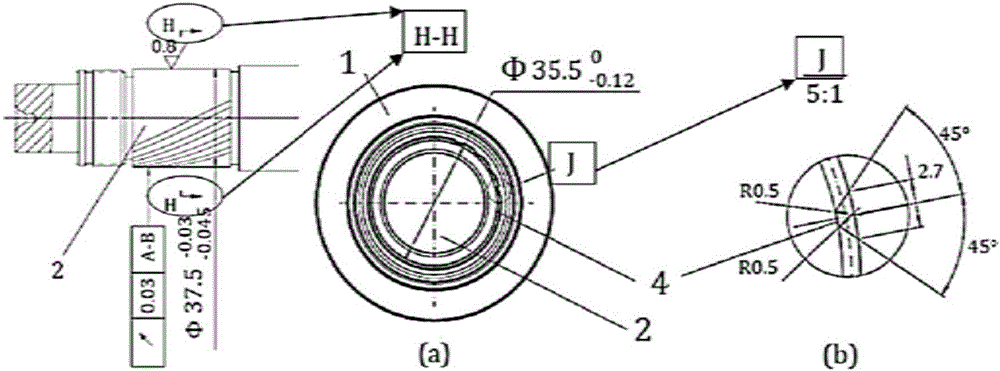

[0026] Such as Figure 4 As shown, the lubricating groove 4 is a toothed groove.

[0027] The number of teeth in the lubricating groove 4 is 19, and the left helix angle is 22°.

[0028]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gap | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com