LED lamp radiator

A technology for LED lamps and radiators, applied in lighting and heating equipment, cooling/heating devices of lighting devices, lighting devices, etc. Performance and other issues, to achieve the effect of improving heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

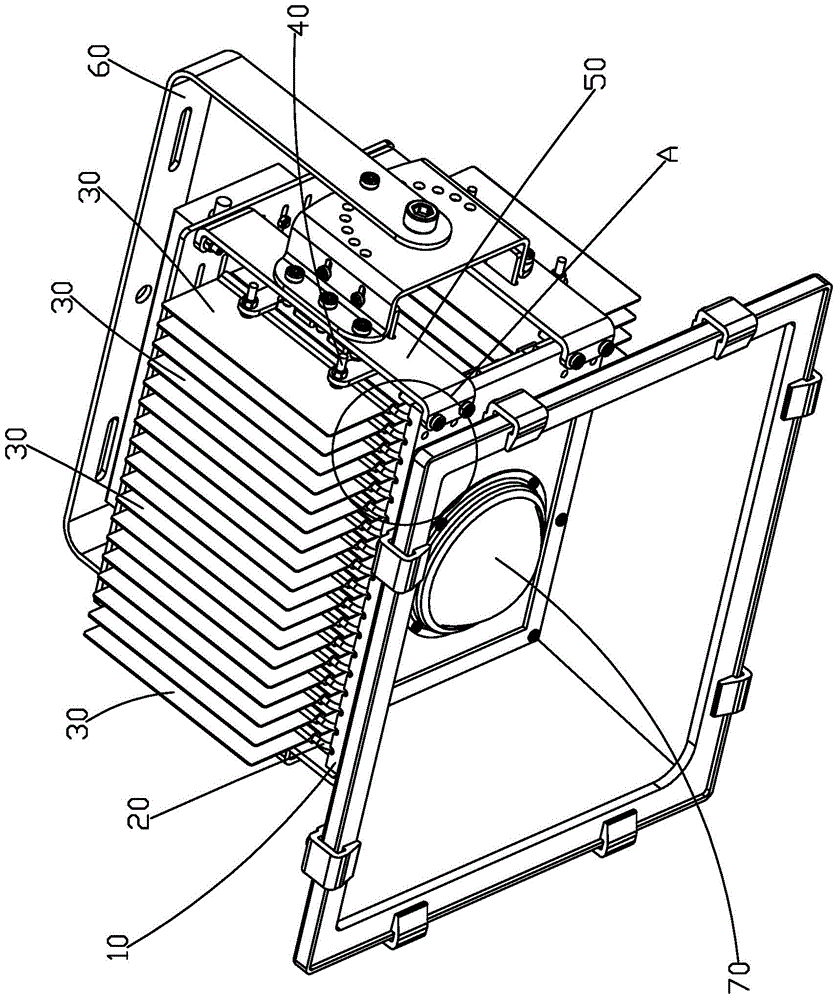

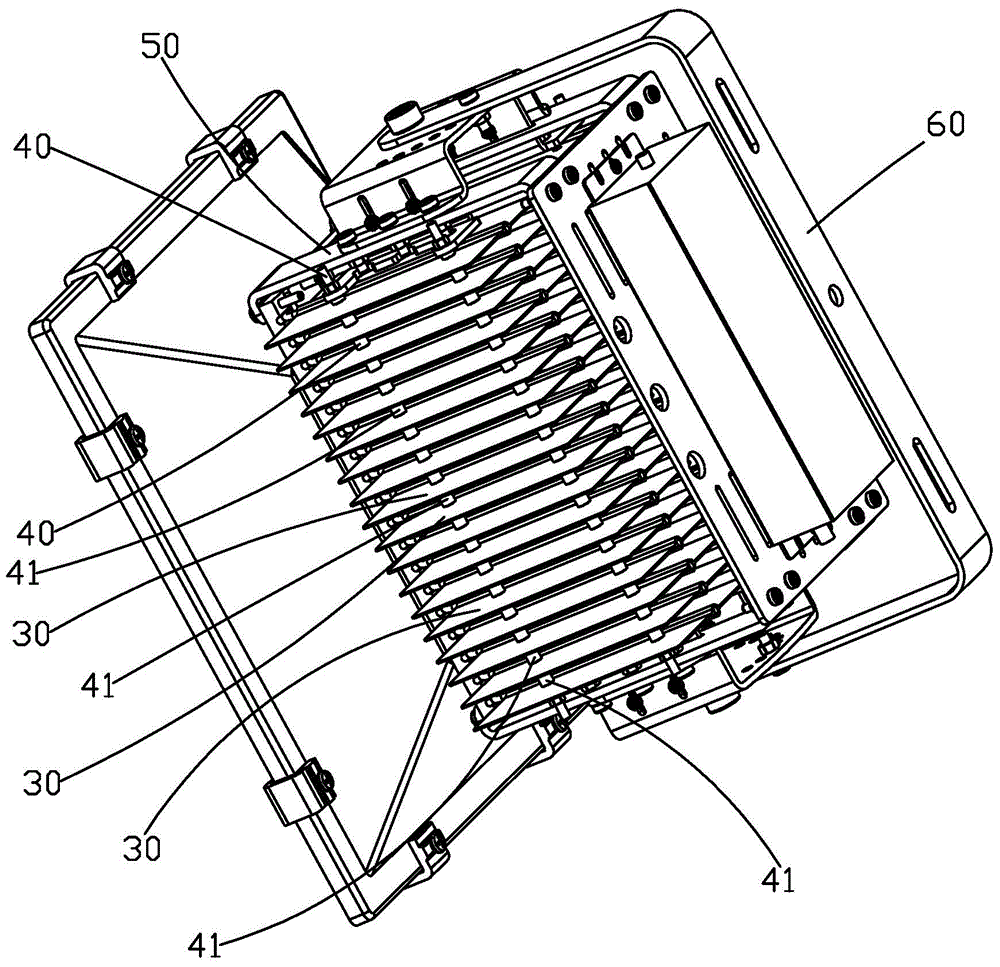

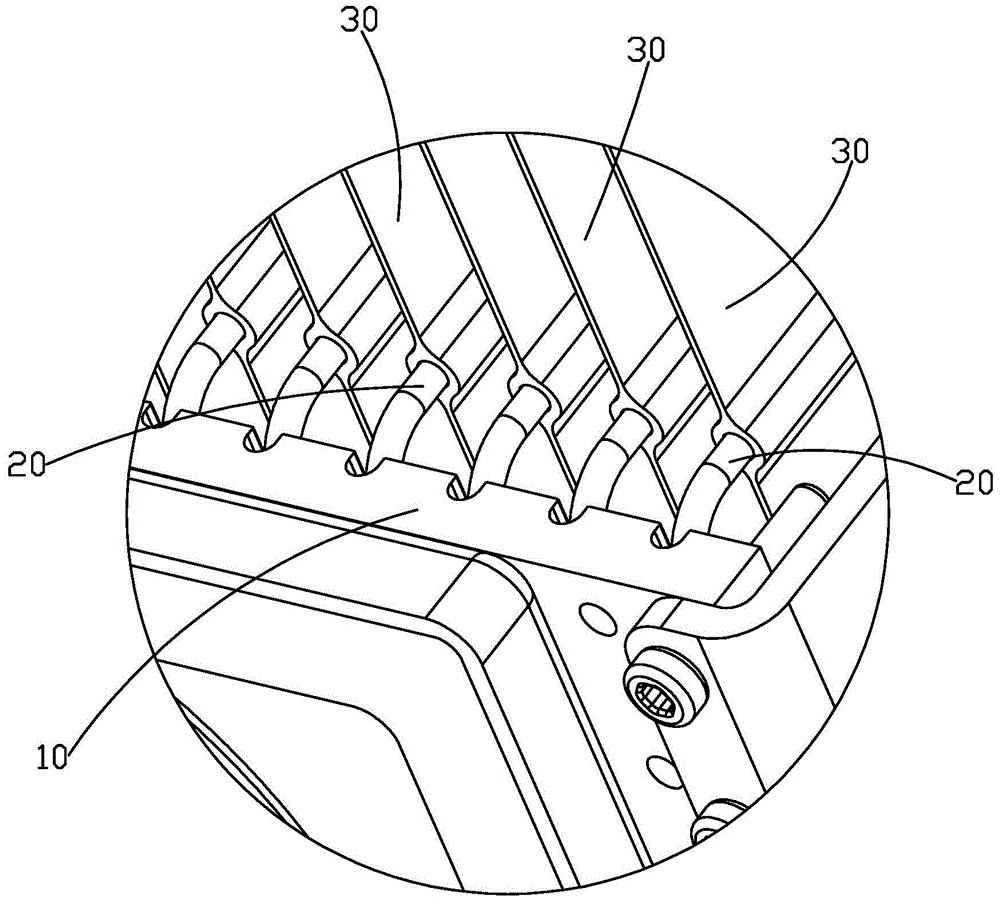

[0024] refer to Figure 1 to Figure 6 , a heat sink for LED lights, including a base 10 for installing a light source 70, a plurality of heat conduction elements 20 are arranged on the base 10, the shape of the heat conduction elements 20 is U-shaped and the heat conduction elements 20 A heat sink 30 is respectively arranged on the two U-shaped arms 21. In the present invention, in order to make the heat generated by the light source 70 work better from the base 10 to the heat sink 30, preferably, the heat conduction Part 20 is a superconducting heat pipe, and heat can be transferred from the base 10 to the heat sink 30 more efficiently by using the superconducting heat pipe to improve the heat dissipation performance of the radiator of the present invention; a plurality of heat conducting parts 20 are arranged in a row at intervals And make the cooling fins 30 on the two U-shaped arms 21 of these heat conducting elements 20 also arranged at intervals to form two rows of cooli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com