Driving mechanism of smoke barrier of smoke exhaust ventilator

A technology of driving mechanism and smoke baffle, which is applied in the direction of oil fume removal, household heating, lighting and heating equipment, etc. It can solve the problems of complex structure, oil fume backflow, flip cover cannot be completely closed, etc., and achieves small size, easy installation and production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

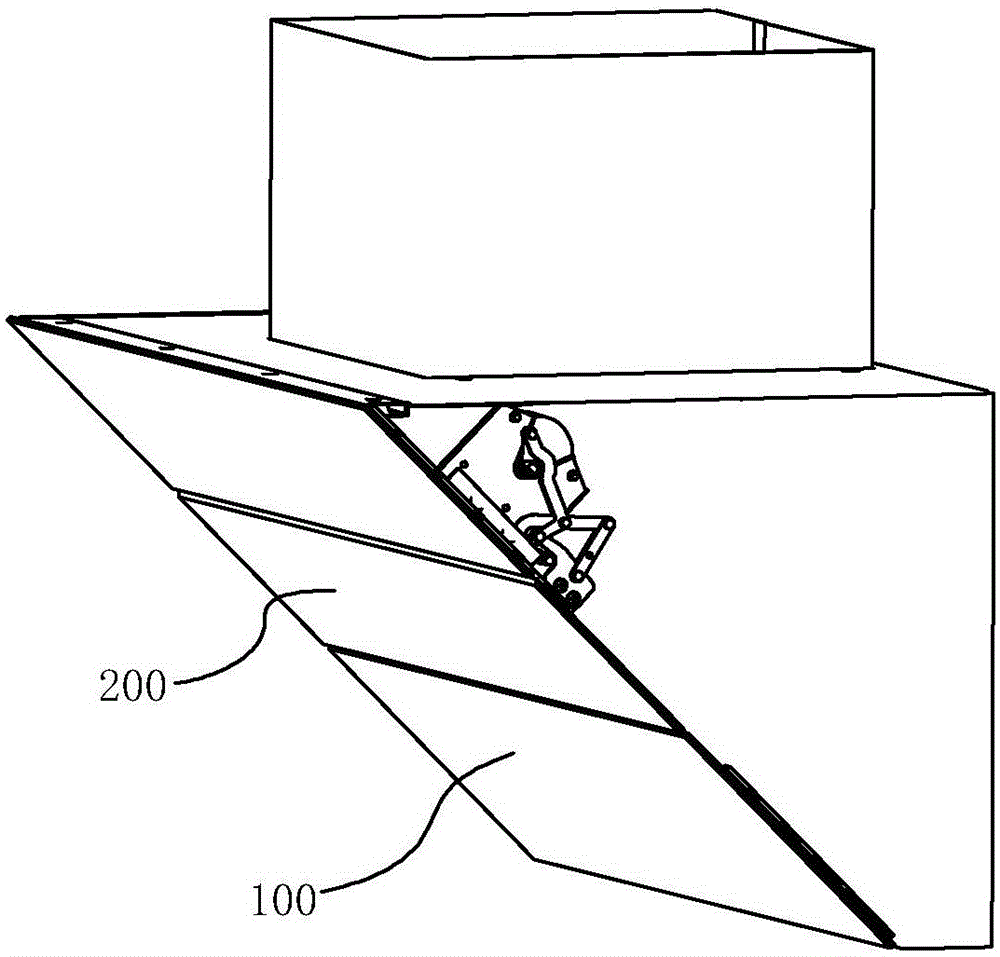

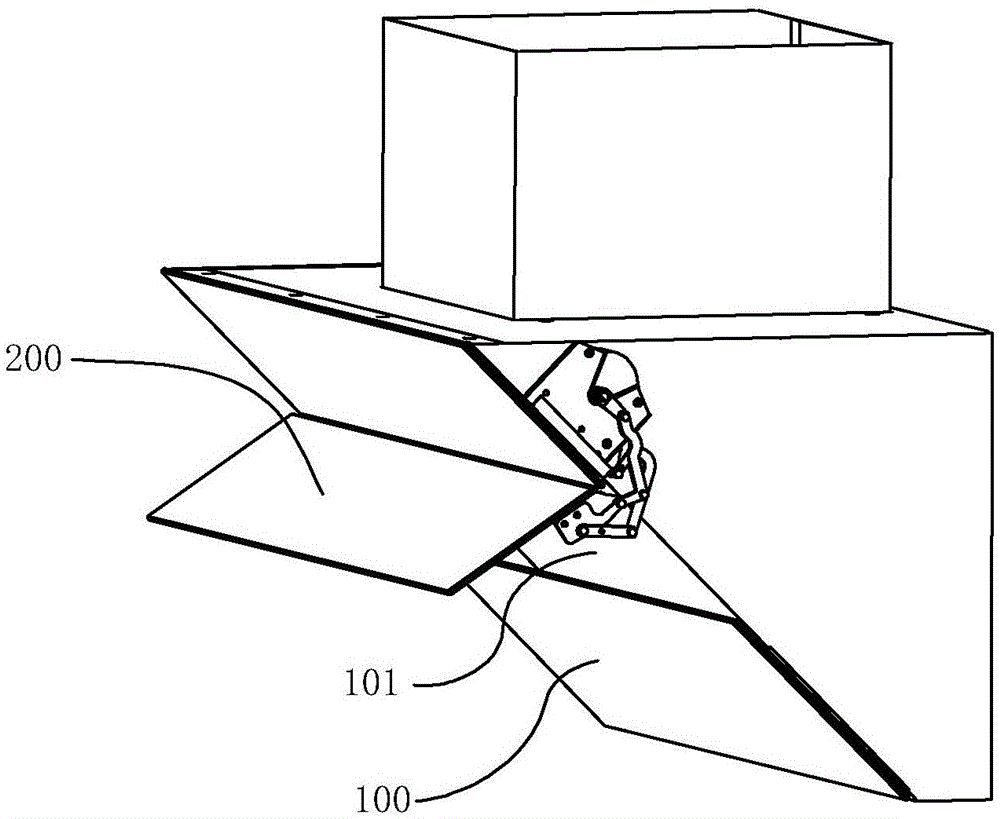

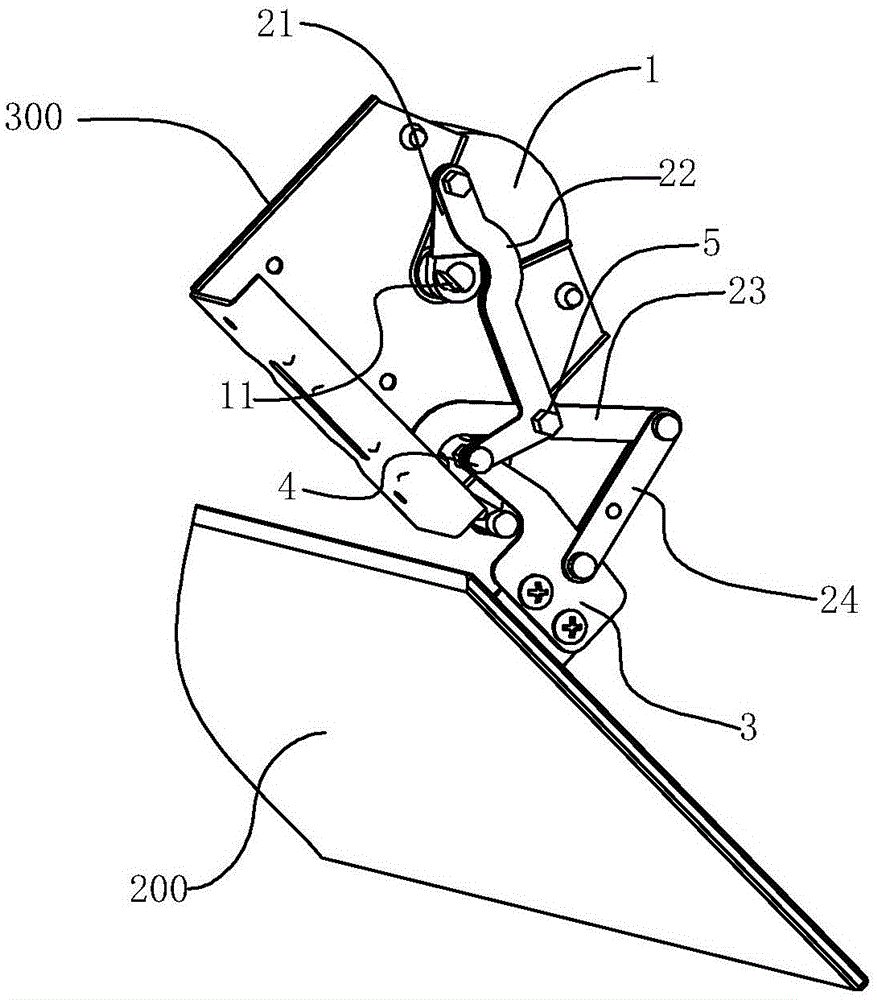

[0031] like Figure 1-5 As shown, the panel 100 of the range hood is arranged obliquely toward the operator, and has an air inlet 101 on it, and a smoke baffle 200 is arranged on the air inlet 101 . The driving mechanism of the smoke baffle plate of the range hood in the embodiment of the present invention includes a drive motor 1, the output shaft 11 of the drive motor 1 performs rotational movement, and the drive motor 1 is fixedly connected to the inner side of the panel 100 of the range hood, and Located above the smoke baffle 200 on the panel 100 . A hinge 4 is fixed inside one end of the smoke baffle 200 , preferably, the hinge 4 is located inside the upper end of the smoke baffle 200 . The driving motor 1 can also be other driving devices, as long as it has a rotating output shaft.

[0032] The driving mechanism of the smoke baffle a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com