A kind of sintering ignition control method of sintering machine

A technology of ignition control and sintering machine, applied in the direction of furnace type, furnace, lighting and heating equipment, etc., can solve the problems of ignition heat loss on material surface, uneven distribution of sintering wind, insufficient ignition heat supply, etc., to reduce ignition fuel and Effect of air flow, optimization of sinter quality, improvement of ignition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

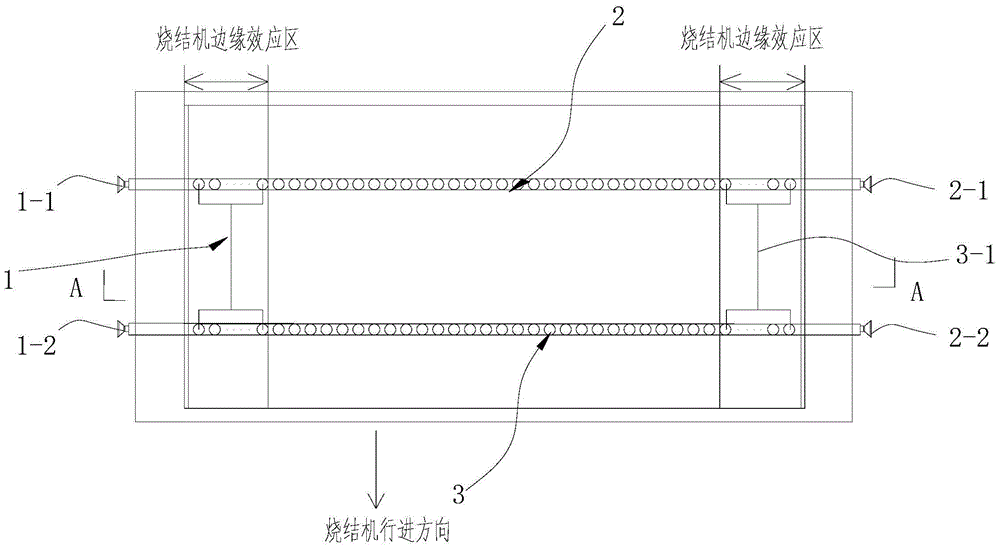

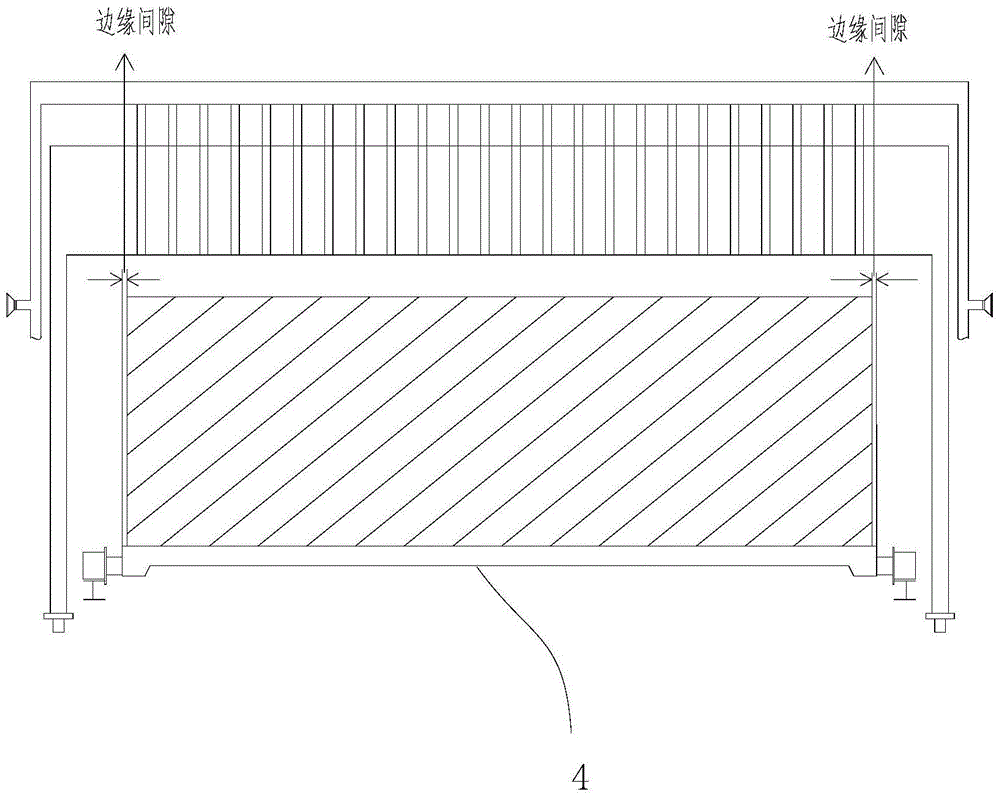

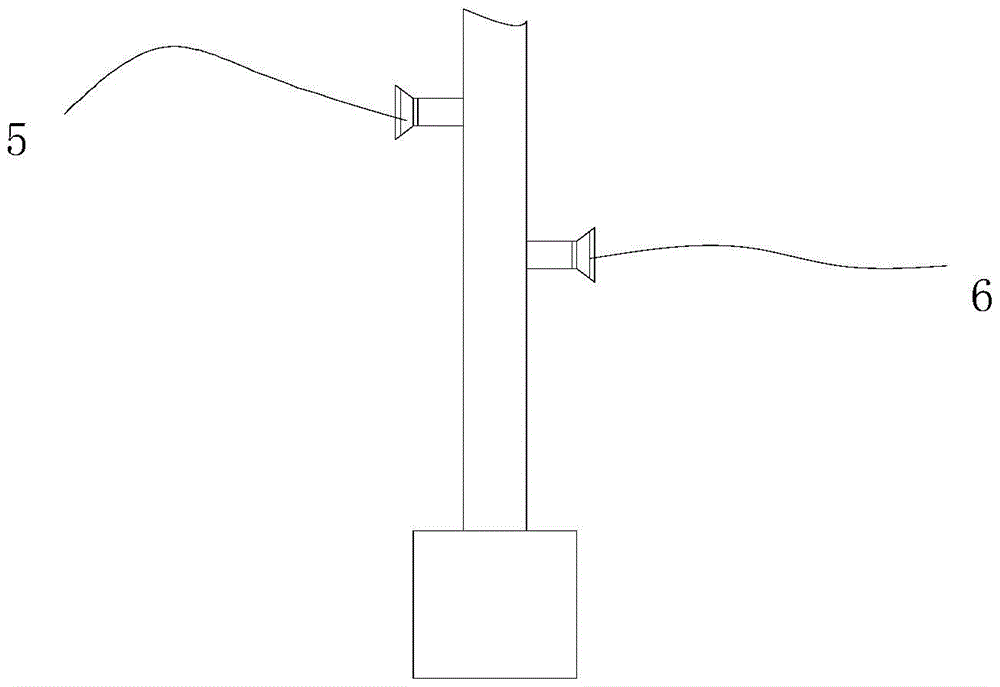

[0019] see Figure 1 to Figure 3 , a sintering ignition control method for a sintering machine, the sintering machine is arranged with several rows of ignition burners, such as the first row of ignition burners 2, the second row of ignition burners 3, etc., and the edge area of the sintering machine is arranged with several rows of edge points Fire burner 3-1, such as the first row of edge ignition burners, the second row of edge ignition burners, etc., the igniter is arranged with several ignition fuel and air flow regulating valves, such as ignition fuel flow regulating valve 1-1 , ignition fuel flow regulating valve 1-2, ignition air flow regulating valve 2-1, ignition air flow regulating valve 2-2, ignition burner fuel flow regulating v...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap