Tool for testing degree of symmetry of gear key groove

A technology of symmetry and gear key, which is applied in the field of gear keyway symmetry inspection tools, can solve the problems of high detection cost, inability to detect the symmetry of gear keyway, complex structure, etc., and achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

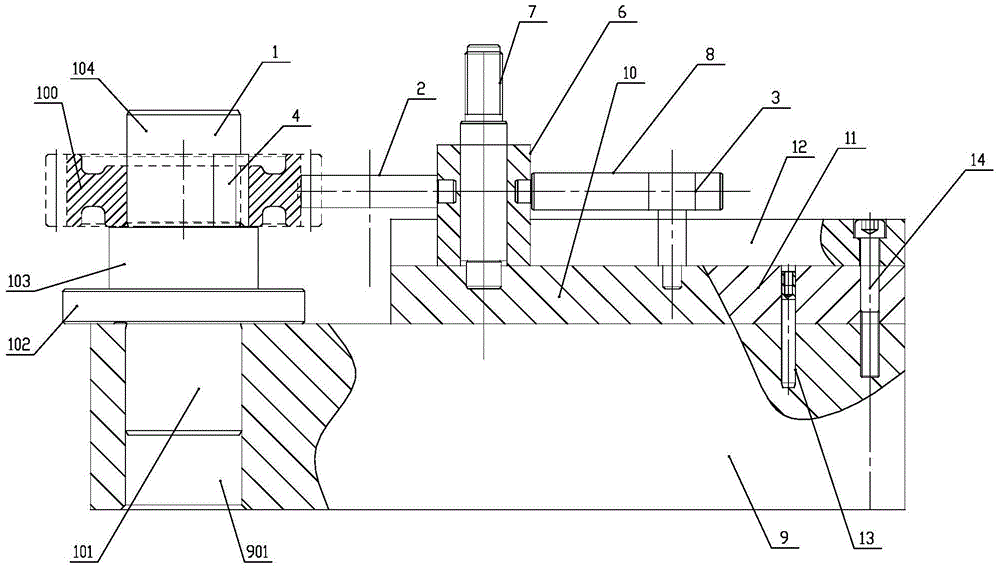

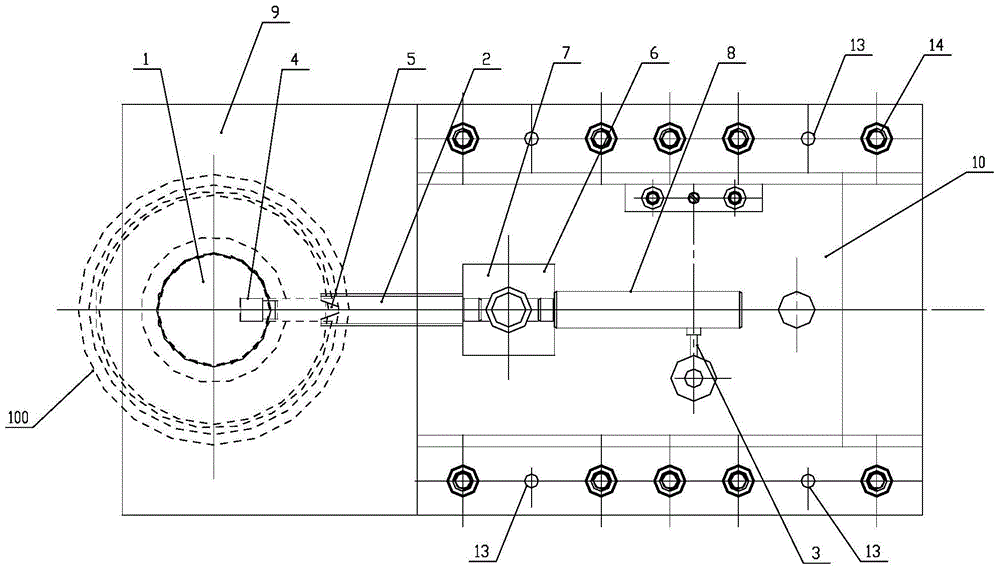

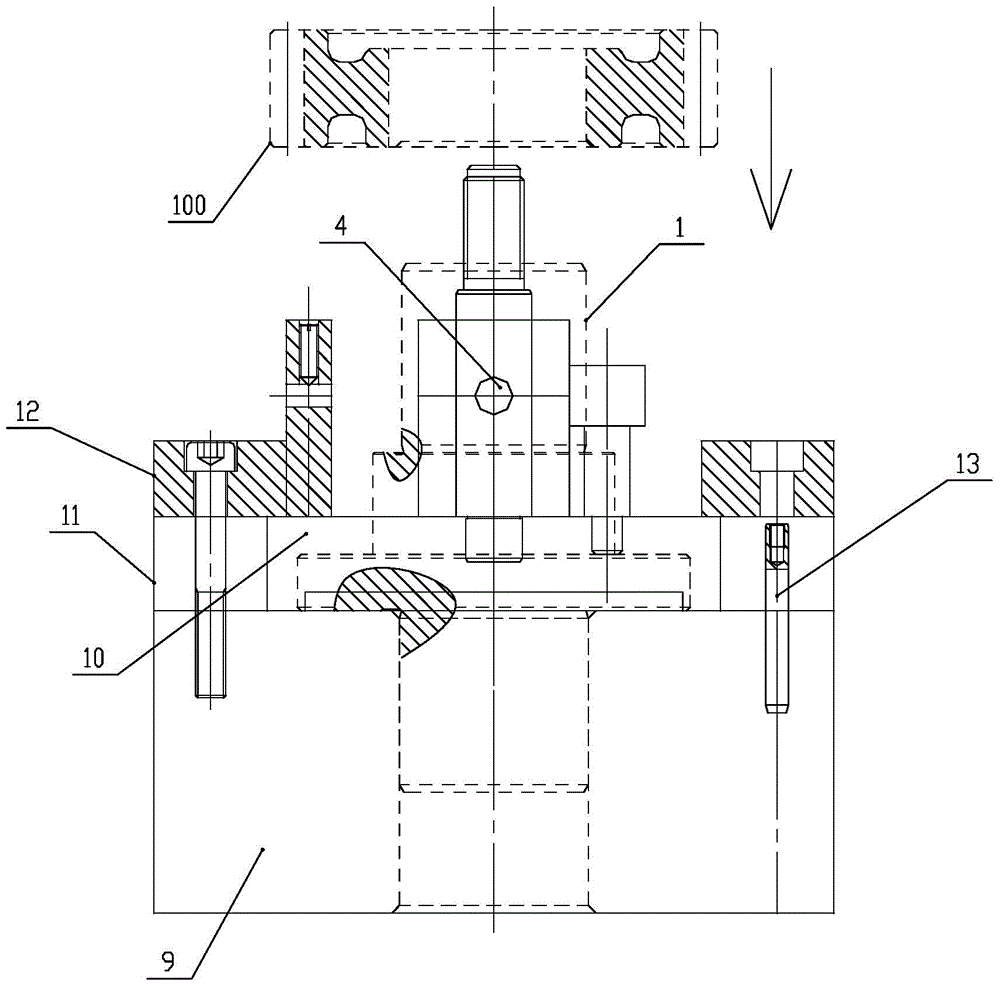

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings, as shown in the figure: the gear keyway symmetry inspection tool of this embodiment includes a mandrel 1 , a measuring column 2 and a dial indicator 3 . The mandrel 1 is a vertical stepped shaft, which includes a bottom shaft section 101, a flange 102, a transition shaft section 103 and an upper shaft section 104 from bottom to top, wherein the bottom shaft section 101 is inserted into the positioning hole 901 on the base 9, and The lower end surface of the flange 102 is lapped on the top surface of the base 9, the outer diameter of the upper shaft section 104 is equal to the diameter of the inner hole of the gear 100, and the gear 100 is inserted into the core from top to bottom along the upper shaft section 104 through its central hole. shaft 1, and the upper end face of the transition shaft section 103 supports the lower end face of the gear 100. In order to measure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com