Detection method of running state of rolling mill position sensor

A detection method and technology for operating status, applied in the field of position sensor working status detection, can solve problems such as frequent failures, sensor wear, abnormal product quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] (1) Detection lag diagnosis: that is, the PLC presets the time Δt for the equipment to run to the given value and the time to reach the given value. The time of the given value is greater than the Δt time, and the PLC will give an alarm;

[0015] Δt=t 2 -t 1 S t 2 -S t 1 2 -S t 1 ) for failure

[0016] S t 2 -S t 1 >100% (S t 2 -S t 1 ) for failure

[0017] t 1 given position start time

[0018] t 2 Time to reach a given location

[0019] S t 1 given position initial value

[0020] S t 2 final value at given position

[0021] S t 2 at t 2 time device position value

[0022] program:

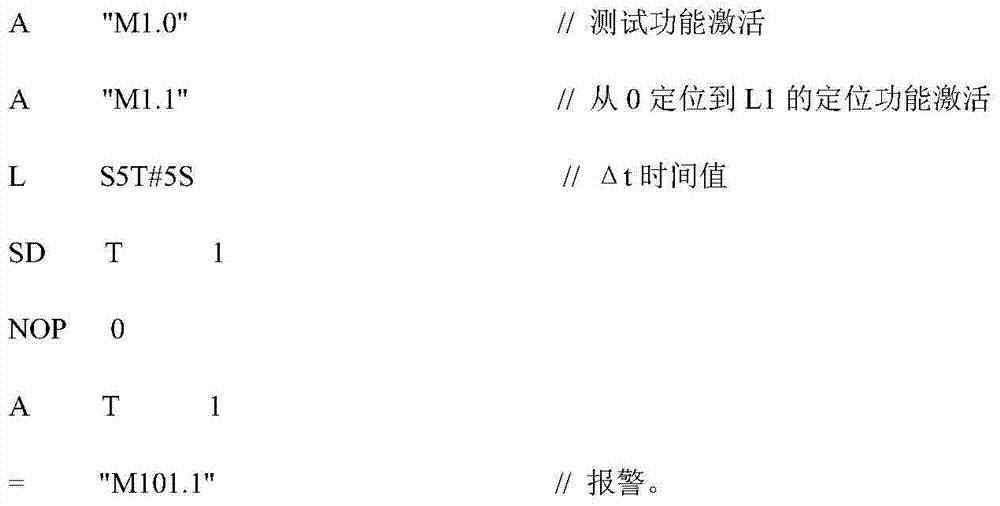

[0023]

[0024] (2) Deviation from the initial value alarm: that is, the PLC sets the initial position value of the position sensor. When the displacement of the position sensor returns to the initial position and deviates from the initial position value, the PLC alarms;

[0025] program:

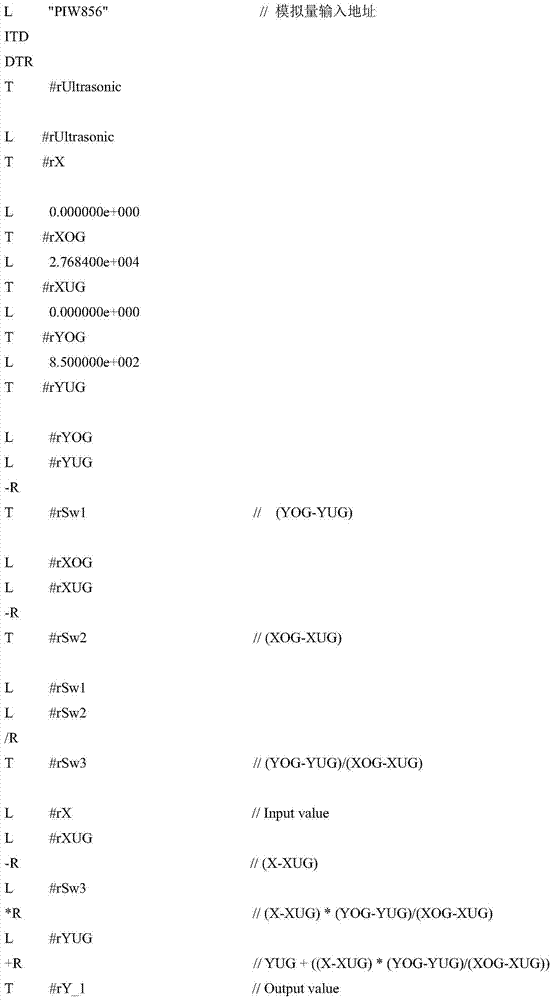

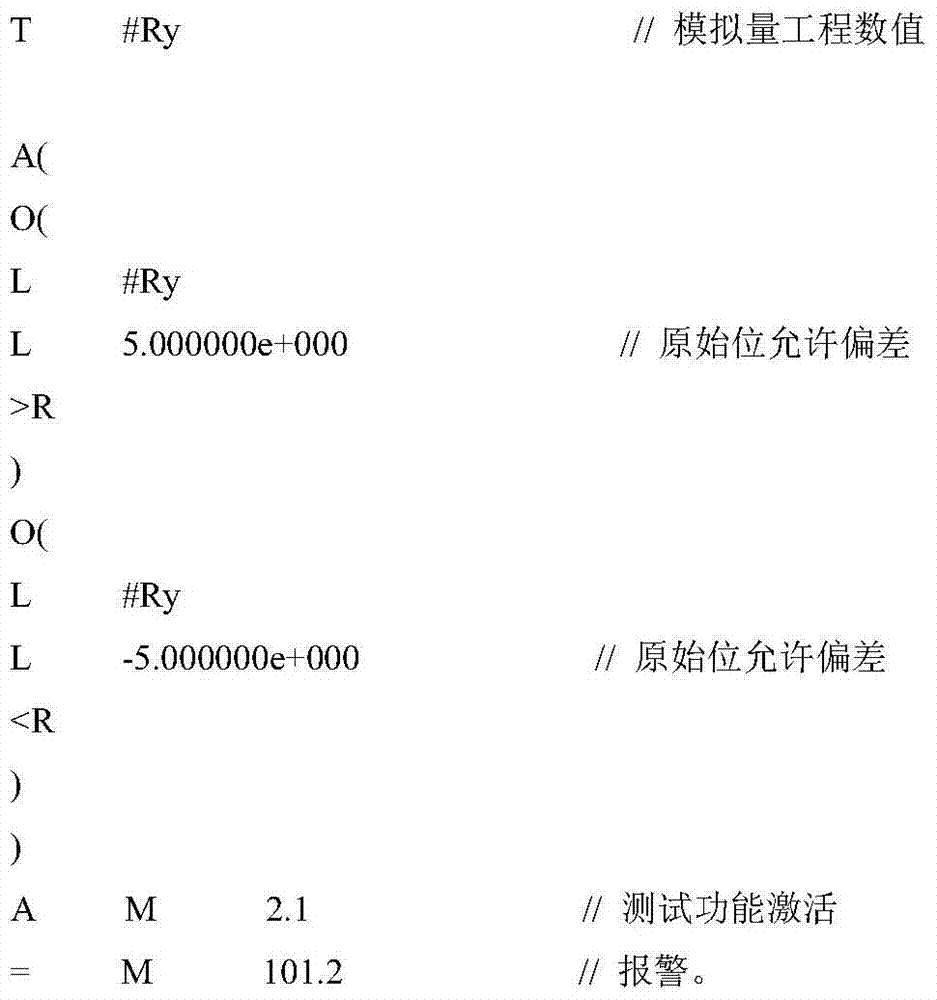

[0026]

[0027]

[0028] (3) The rate of change of the signal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com