Survey mark used for control point of prefabricated structure and positioning method employing survey mark

A technology of measuring marks and prefabricated structures, which is applied in the direction of measuring point marks, etc., can solve problems such as difficult to determine precise positions, wear and tear, and easy deviation, and achieve the effects of easy guarantee of depth and position, improvement of pre-embedding accuracy, and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

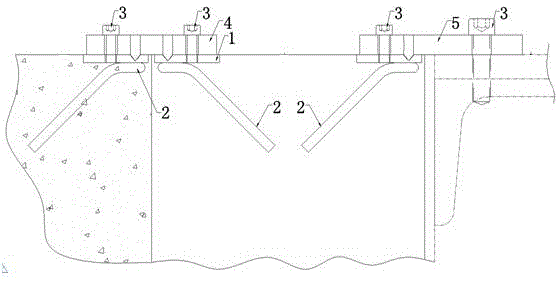

[0013] control figure 1 It can be seen that a measurement mark for a control point of a prefabricated structure comprises a pre-embedded steel plate 1, an anchoring steel bar 2, a positioning steel plate 4 and an anchoring steel plate 5, the side length of the pre-embedded steel plate is 40mm*60mm, and the thickness is 5mm. Bolt holes corresponding to the bolts are provided on the pre-embedded steel plate, and a measuring tapered hole is provided at the center, the anchoring steel bar is welded to the pre-embedded steel plate, the width of the positioning steel plate is consistent with the pre-embedded steel plate, and the length is Twice as much as the embedded steel plate, four bolt holes corresponding to the embedded steel plate are opened on the positioning steel plate, and conical raised blocks are set at the corresponding positions, the positioning steel plate and the embedded steel plate are connected by anchor bolts 3, One side of the anchoring steel plate is provided ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com