Soil in-suit boring shearing testing device

A testing device and soil technology, applied in directions such as applying stable shear force to test material strength, applying stable tension/compression to test material strength, etc., can solve the problem that absolute flatness cannot be guaranteed and the test instrument is perpendicular to the axis of the hole. Problems such as the inability to install the test device normally and the complex structure, etc., achieve the effect of simple structure, simple and accurate data, and small disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings. The specific embodiments described here are only used to explain the present invention, not to limit the present invention.

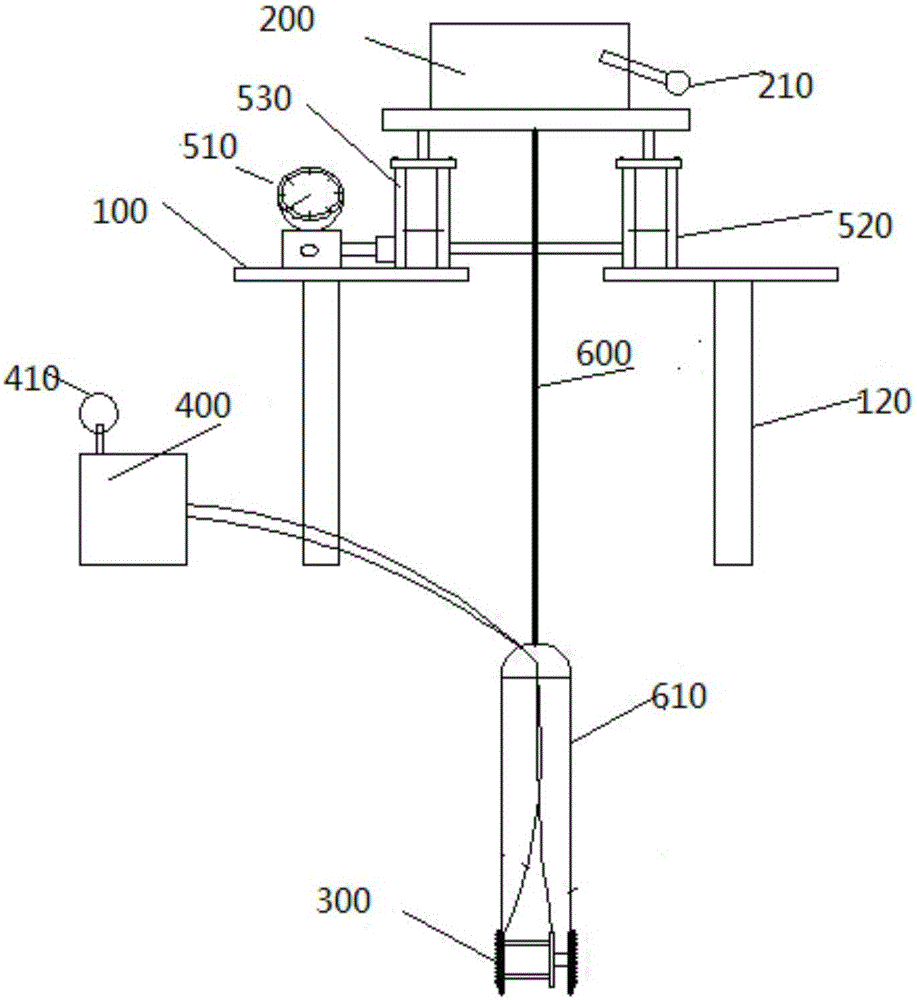

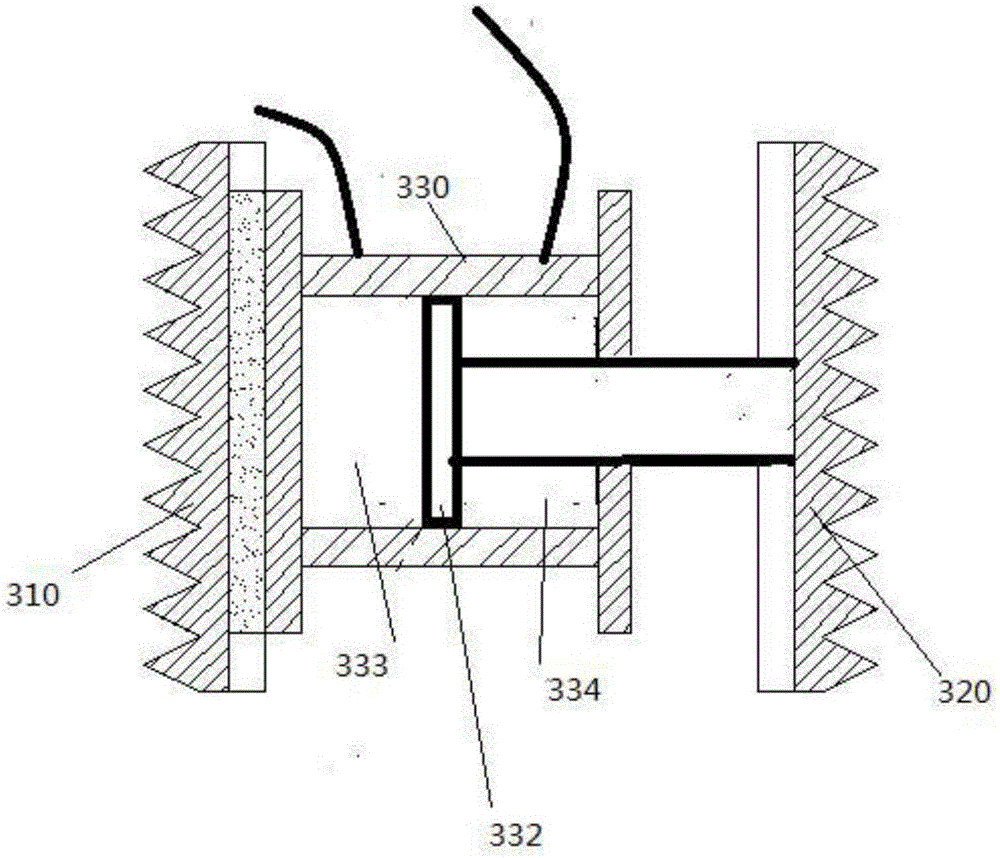

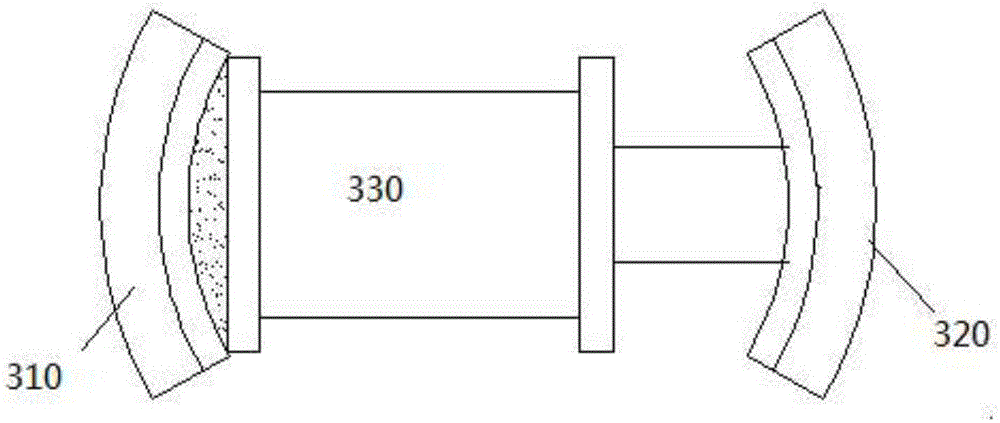

[0016] Such as Figure 1-Figure 4 It can be seen that the soil in-situ drilling shear test device of the present invention is mainly composed of an operating platform 100, a vertical tension mechanism 200, a shear probe 300, a supporting cylinder and a pressurized air pump 400; the operating platform 100 is a four-legged support (120 is one of the supports); a pair of support cylinders (520 and 530) support the vertical tension mechanism 200 on the operating platform 100; one end of the pull rod 600 is connected to the power output end of the vertical tension mechanism 200, and its One end hangs the shearing probe 300 through the flexible hanging cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com