Pressure testing machine for propping agent test

A pressure test and proppant technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of numerical inaccuracy of crushing rate, high noise of hydraulic source, high maintenance cost of hydraulic components, etc. The wheel mechanism is simplified, the high processing cost is avoided, and the effect is remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

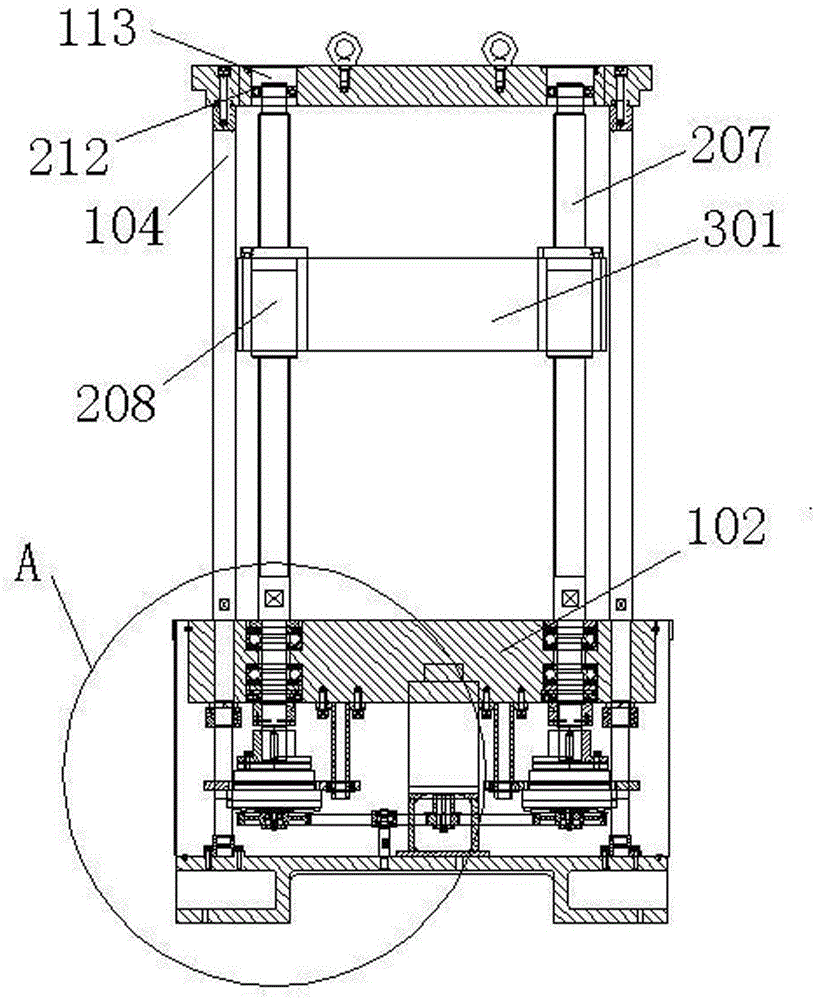

[0025] The technical scheme of the present invention will be described in detail below in conjunction with the accompanying drawings.

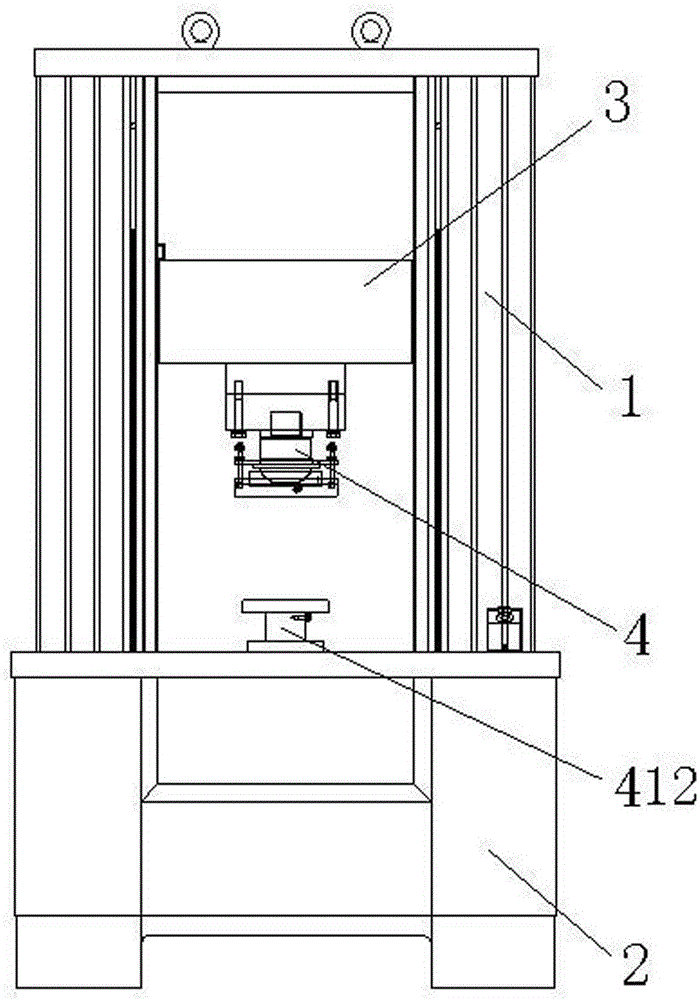

[0026] Such as figure 1 As shown, a pressure testing machine for proppant testing of the present invention is mainly used in "ISO13503-2 Pressure Proppant Performance Evaluation Method", "SY / T5108-2006 Fracturing Proppant Performance Index and Test Recommended Method", The test of proppant anti-fragmentation ability in "Q / SY125-2007 Fracturing proppant performance tabulation and evaluation test method" and "SY / T6302-2009 Recommended method for short-term conductivity evaluation of fracturing proppant packing layer" Test the short-term conductivity of the proppant pack. It is mainly composed of a main frame 1, a transmission system 2, a beam adjustment mechanism 3 and a pressing plate assembly 4.

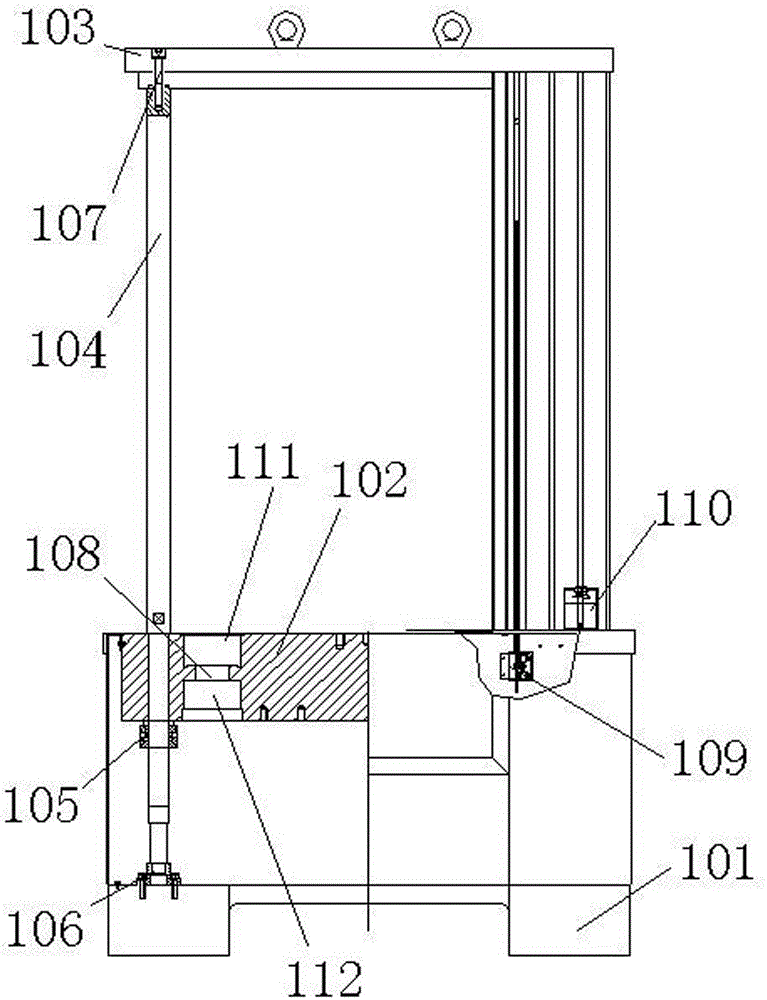

[0027] Such as figure 2 As shown, the main frame 1 includes a base 101 , a lower beam 102 , an upper beam 103 and a column 104 .

[0028] The m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com