Graphene-based spatial electro-optic modulator

An electro-optical modulator, graphene technology, applied in instruments, optics, nonlinear optics, etc., can solve the problems of large equivalent capacitance, modulation speed limitation, high electromagnetic loss, etc., to achieve small equivalent capacitance, easy integration, The effect of high modulation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

[0023] The following examples select a single-sided polished silicon wafer as the substrate, evaporate 150nm silver on the substrate by electron beam evaporation, deposit 16nm hBN on the Ag by radio frequency magnetron sputtering, and then use the method of chemical deposition , let graphene grow on hBN, and then use plasma chemical deposition method to form 1nm hBN on graphene. Finally, the silver bar block on the top layer is obtained by nanoimprinting method.

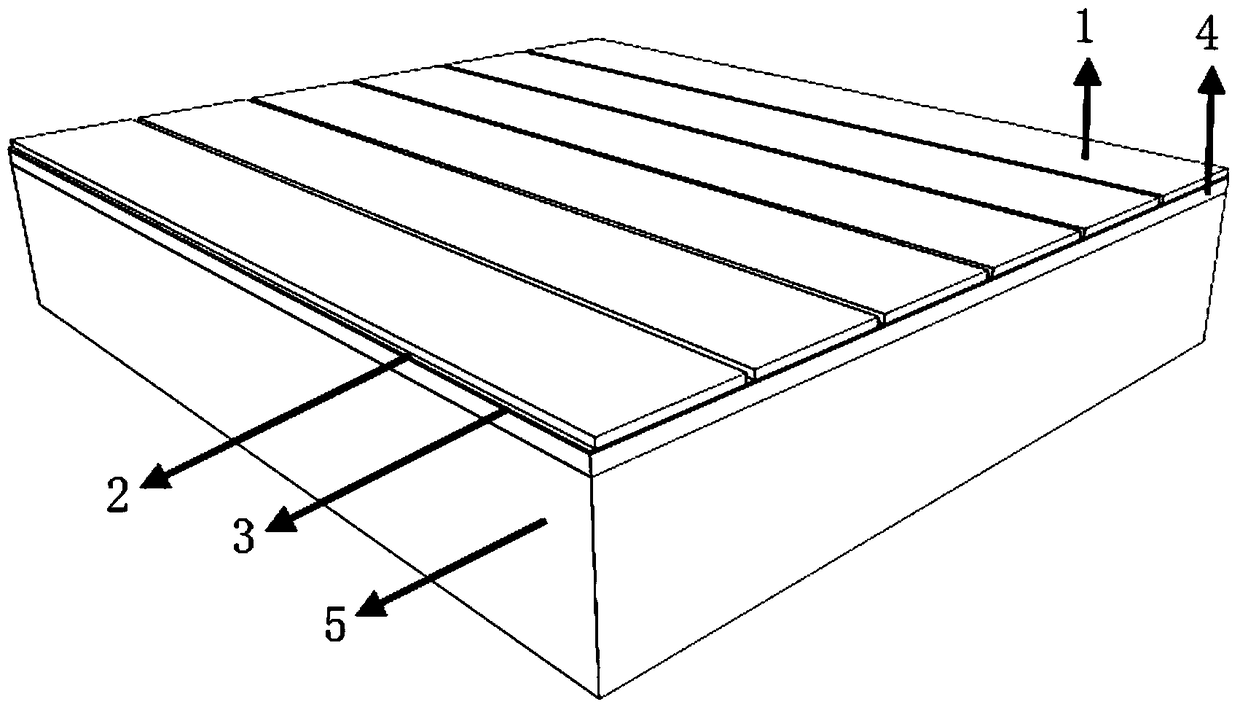

[0024] What the present invention adopts is metal layer-dielectric layer-metal layer (Metal-Dielectric-Metal) structure, and its composition sees figure 1 .

[0025] The present invention has a 5-layer structure, with an upper silver layer 1, an upper hexagonal boron nitride (hBN) layer 2, a graphene monoatomic layer 3, a lower hexagonal boron nitride (hBN) layer 4 and a lower silver layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap