Projector type automatic dustproof system

A projector, automatic technology, applied in optics, instruments, projection devices, etc., can solve the problems of affecting picture quality, inability to set up protective filters to prevent dust, contamination of lenses and projector circuit boards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

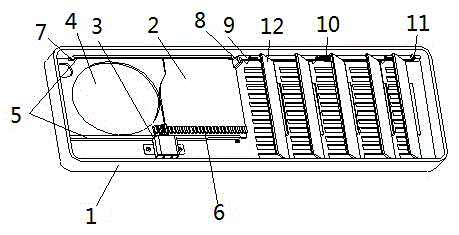

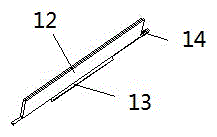

[0020] combine figure 1 , 2 As shown, the projector automatic dustproof system includes a projector front cover 1, a lens cover 2, and a stepping motor 3. A lens hole 4 is opened on the inside of the projector front cover relative to the position of the lens on the projector. Both sides of the lens hole are provided with parallel and opposite guide rails 5, and the lens cover includes a plate body, which is provided with parallel end edges, and the plate body is connected to the guide rails through its end edges, A tooth structure 6 protruding from the plate is provided along one end edge of the plate body, and the tooth structure 6 is connected to the stepping motor.

[0021] A limiting structure 7 is provided at the tail end of the guide rail.

[0022] A push rod 8 is arranged on the tail of the end of the plate body away from the tooth structure.

[0023] A rack 9, a spring 10, and a position detection element 11 are arranged on the inside of the front cover of the proje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com