Pin inserting machine achieving automatic forming

A technology of automatic forming and pin insertion machine, which is applied in the direction of coil manufacturing, etc., can solve the problems of increasing product cost, rising labor costs, low production efficiency, etc., and achieve the effects of improving production efficiency, easy maintenance and inspection, and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

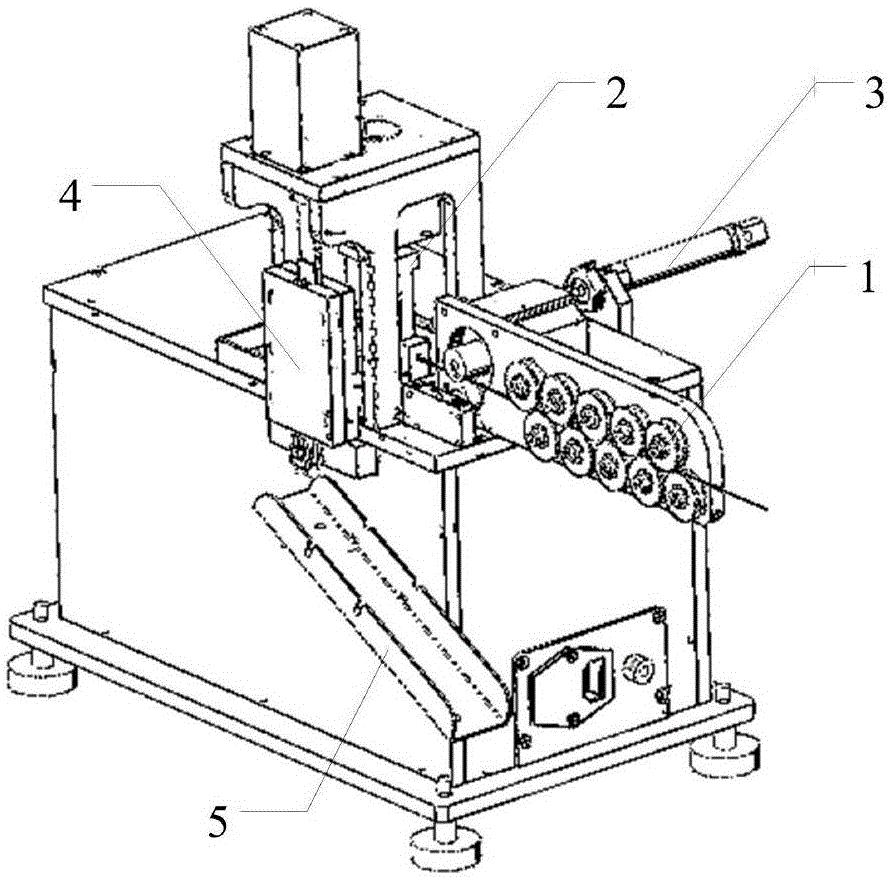

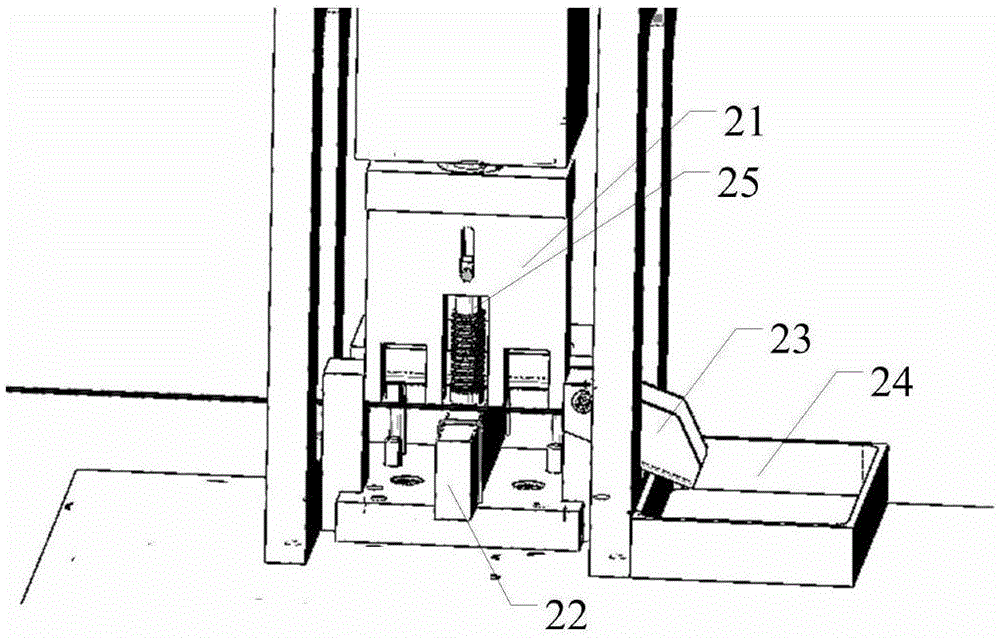

[0020] figure 1 is a schematic diagram of the present invention. The present invention includes an operation platform, on which a pressing assembly 1, a forming assembly 2, a pushing assembly 3, and an installation assembly 4 are arranged, and a driving cylinder for driving each assembly is also included. The pressing component 1 straightens the untreated bent copper wire, and then sends it to the forming component 2. The forming component 2 presses the copper wire into a U shape, and the pushing component 3 pushes the U-shaped copper wire into the installation component 4. Component 4 loads the copper wire into the skeleton.

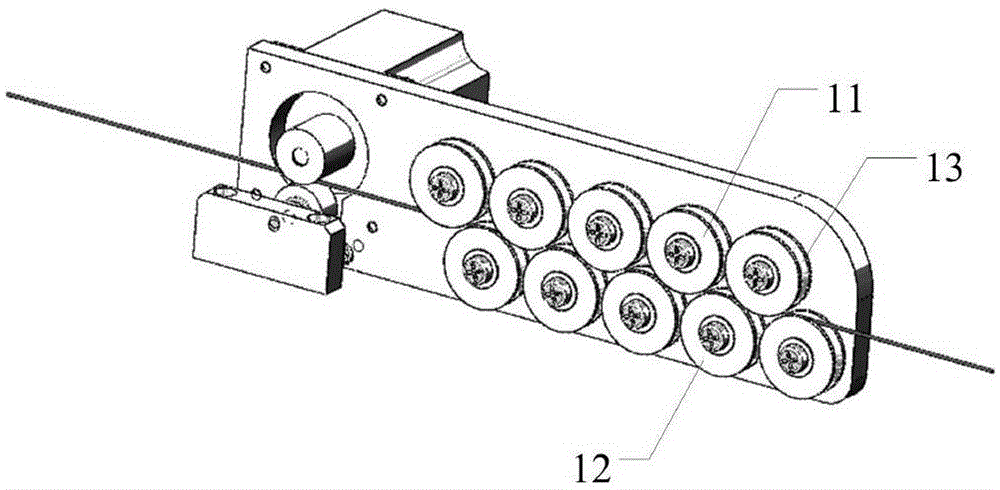

[0021] figure 2 is a schematic diagram of the pressed assembly. The pressing assembly 1 is provided with an upper set of guide bearings 11 and a lower set of guide bearings 12, and the edges of the upper set of guide bearings 11 and the lower set of guide bearings 12 are provided with grooves 13; the edges of the upper set of guide bearings 11 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com