Equipment and method for automatically disassembling and recycling power battery

A technology for power batteries and recycling equipment, applied in battery recycling, recycling technology, recycling by waste collectors, etc., can solve problems such as health hazards, battery short-circuit fire, and safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

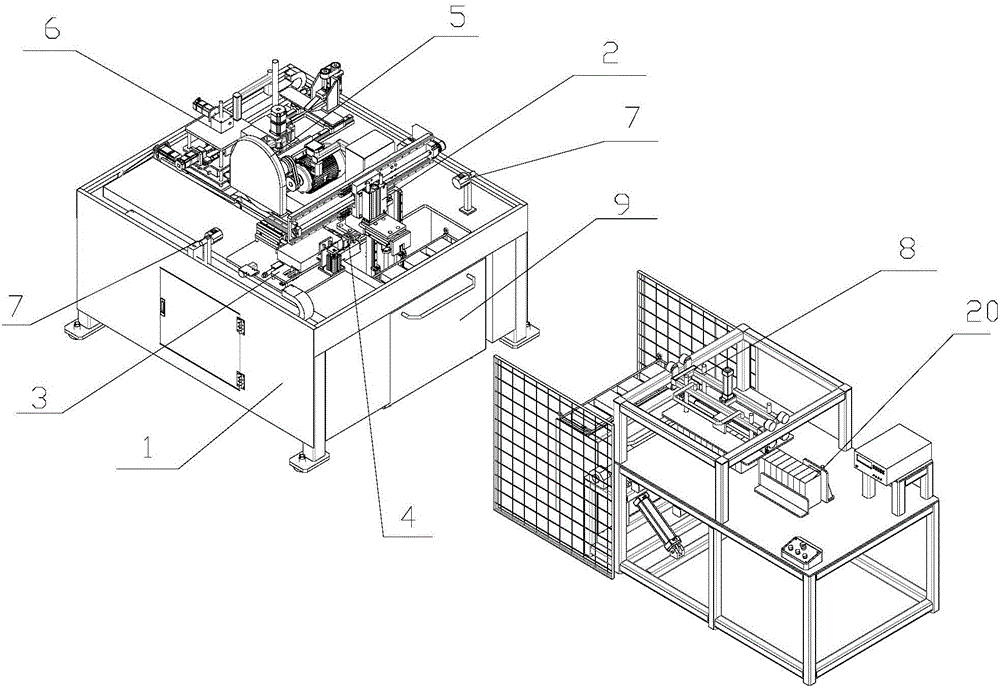

[0074] Such as figure 1 As shown, the power battery automatic dismantling and recycling equipment in this embodiment includes a frame 1, a feeding manipulator 2, a horizontal moving platform 3, a clamping and positioning mechanism 4, a cutting mechanism 5, a coring mechanism 6, and a visual system 7, and assists in loading Feeding device 8, and feeding bin 9. The power battery automatic dismantling and recycling equipment can realize a series of automatic processes such as loading, clamping, cutting of the battery head, separation of the battery cell and the battery case, and blanking of the lithium-ion power battery. At the same time, it cooperates with the vision system to realize the entire Visual remote monitoring of the process.

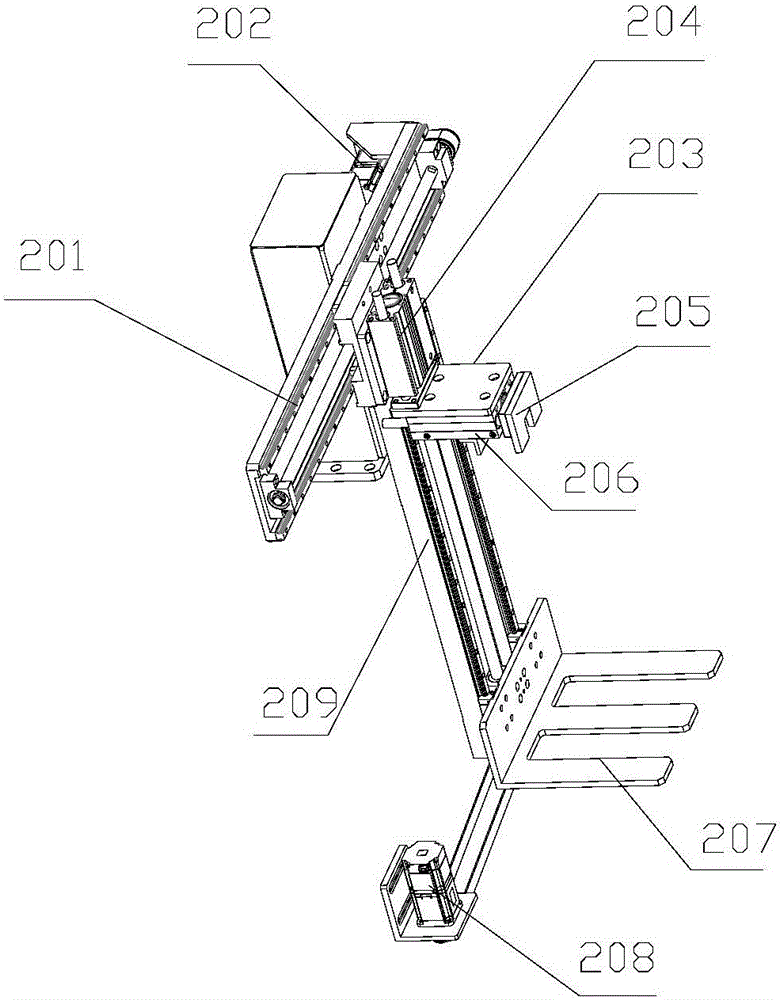

[0075] In this embodiment, the structural diagram of the feeding manipulator can be found in figure 2 , The feeding manipulator is mainly composed of a Y-axis manipulator 201, a Z-axis manipulator 203, a gripper mechanism, and a lifting mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com